Acid Resistant Mortar Powder

MOQ : 20 MT Metric Tons

Acid Resistant Mortar Powder Specification

- Melting Point

- >1700C

- Water Absorption

- <1%

- Application

- Industrial flooring, chemical plants, acid storage tanks, reactors, effluent treatment plants

- Purity(%)

- 98%

- Chemical Composition

- Silica-based compound

- Density

- 2.1 Gram per cubic centimeter(g/cm3)

- Surface Finish

- Smooth, even

- Form

- Powder

- Usage & Applications

- Acid proof lining, flooring, and joint filling

- Hardness (%)

- Up to 98%

- Product Type

- Refractories

- Types of Refractories

- Acid Resistant

- Shape

- Powder

- Porosity

- Low

- Dimensional Stability

- Excellent dimensional stability under severe chemical attack

- Strength

- High compressive and bonding strength

- Specific Gravity

- 2.2 to 2.4

- Thermal Conductivity

- Low

- Color

- Grey

Acid Resistant Mortar Powder Trade Information

- Minimum Order Quantity

- 20 MT Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Days after Acceptance (DA), Letter of Credit (L/C), Western Union, Delivery Point (DP), Telegraphic Transfer (T/T)

- Supply Ability

- 1000 Metric Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, Eastern Europe, Middle East, Central America, South America, Africa

About Acid Resistant Mortar Powder

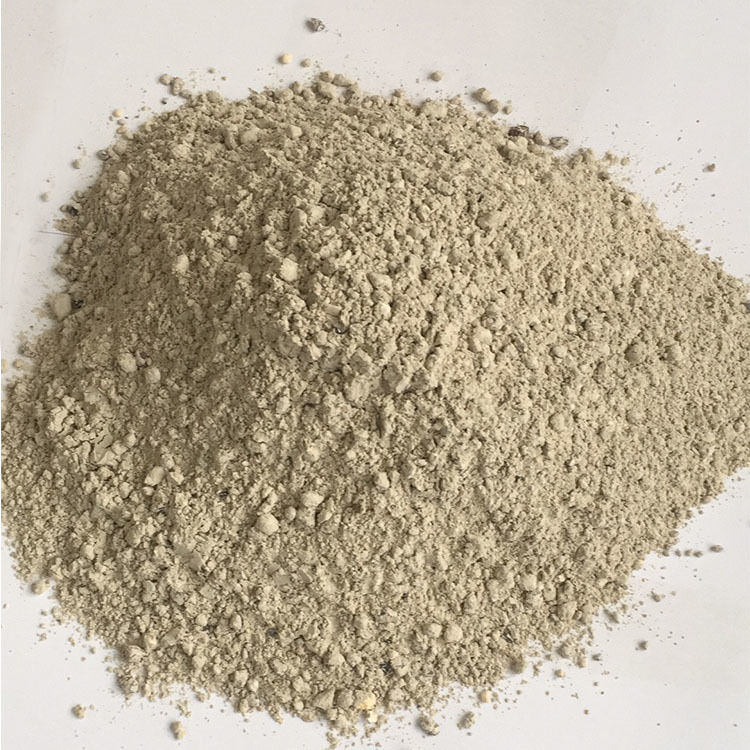

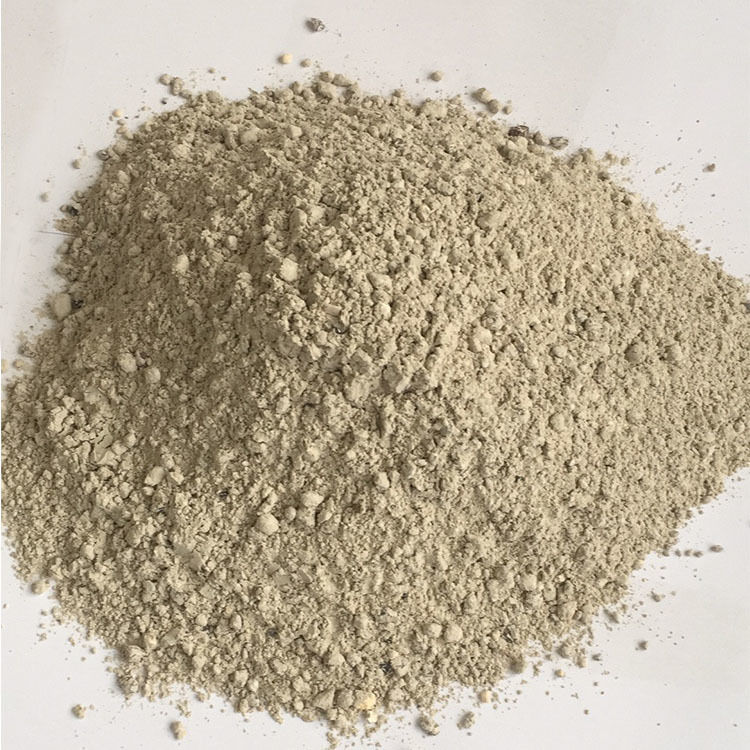

Acid Resistant Mortar Powder

Acid Resistant Mortar Powder exhibits excellent adhesion to acid resistant bricks/tile, concrete, MS surface. This powder is very effective and is resistant to wide range of chemicals. This powder has very low absorption and very high chemical & physical properties. This powder is tested under numerous parameters to ensure its effectiveness and flawlessness. Acid Resistant Mortar Powder can be used for acid resisting brick/tile lining. This powder is very cost effective and can be easily availed at cheaper rates, in bulk quantities.

Superior Chemical Resistance

Designed with a robust silica-based composition, this mortar is resistant to both strong acids and alkalis (excluding hydrofluoric acid). Its high purity and dense structure help safeguard critical infrastructure in chemical plants and storage areas from corrosive damage.

Easy Handling and Application

Packaged in 25 kg or 50 kg HDPE bags for easy transport and storage, the powder mixes well, cures in air, and spreads smoothly, ensuring an even, secure finish. Its quick initial set of 4-6 hours allows for efficient operational turnaround, making it suitable for time-sensitive projects.

Long-Term Performance and Stability

Thanks to its excellent dimensional stability, low water absorption (below 1%), high hardness (up to 98%), and minimal thermal conductivity, the mortar keeps structures protected under extreme chemical attack and elevated temperatures, maintaining integrity for years.

FAQ's of Acid Resistant Mortar Powder:

Q: How is Acid Resistant Mortar Powder typically used in industrial applications?

A: This mortar is mainly used for acid proof lining, flooring, and joint filling in industrial settings such as chemical plants, acid storage tanks, reactors, and effluent treatment plants. It creates a dense and durable barrier against aggressive chemicals.Q: What is the recommended curing process for this mortar powder?

A: After application, the mortar is air-cured, which eliminates the need for water curing. It achieves its initial set within 4-6 hours, with final strength developing after 24 hours, ensuring strong chemical bonding and surface integrity.Q: When should Acid Resistant Mortar Powder be applied during construction projects?

A: The mortar is ideal for installation at any project stage where acid and alkali protection is crucial, particularly before any chemical exposure occurs. Ensure the substrate is clean and dry before application for optimal bonding.Q: Where should I store the mortar powder to maintain its shelf life?

A: For maximum efficacy, store the mortar in its original sealed HDPE bags in a cool, dry place, away from moisture and direct sunlight. Under these conditions, it retains its properties for at least 12 months.Q: What are the key benefits of using this silicate-bonded mortar?

A: Key benefits include excellent acid and alkali resistance, high compressive and bonding strength, smooth surface finish, low porosity and water absorption, as well as proven dimensional stability under severe chemical attack.Q: Is there any acid the mortar cannot withstand?

A: Yes, while the mortar resists most strong acids and alkalis, it is not suitable for use with hydrofluoric acid, which can compromise both silica and silicate bonds.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Acid Resistant Products Category

Acid Resistant Tiles

Price Range 2.10 - 4.50 USD ($) / Square Meter

Minimum Order Quantity : 3000 Square Meters

Shape : Other, Rectangular, Square

Product Type : Refractories

Acid Proof Bricks

Price Range 0.15 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Shape : Brick

Product Type : Refractories

Acid Resistant Bricks

Price Range - 2.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Shape : Brick

Product Type : Refractories

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry