Bottom Pouring Sets

Bottom Pouring Sets Specification

- Surface Finish

- Smooth, well cured

- Hardness (%)

- Approx. 65% 70%

- Chemical Composition

- Al2O3, SiO2, CaO, Fe2O3; Alumino-Silicates

- Water Absorption

- 10% 15%

- Usage & Applications

- Bottom Pouring of Ingots, Steel Casting

- Melting Point

- Up to 1700C

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Purity(%)

- 85% 92% (Alumina & Silica)

- Application

- Used in steel and foundry industries for bottom pouring of molten metal in ingots

- Form

- Sets/Built assemblies

- Product Type

- Refractories

- Types of Refractories

- Fireclay, High Alumina

- Shape

- Round, Oval, Custom Shapes

- Porosity

- 18% 22%

- Dimensional Stability

- High dimensional stability at elevated temperatures

- Strength

- Cold Crushing Strength > 350 kg/cm

- Specific Gravity

- 2.3 2.6 g/cm

- Thermal Conductivity

- Low thermal conductivity (0.350.65 W/mK at 1000C)

- Color

- Light Brown / Beige

Bottom Pouring Sets Trade Information

- Minimum Order Quantity

- 400 Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Days after Acceptance (DA)

- Supply Ability

- 4000 Metric Tons Per Month

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

About Bottom Pouring Sets

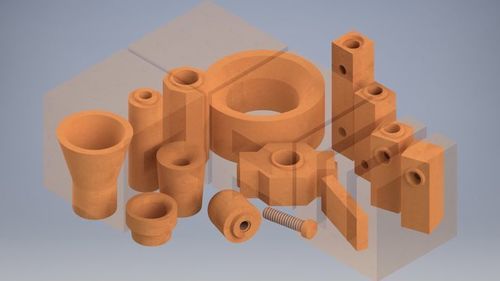

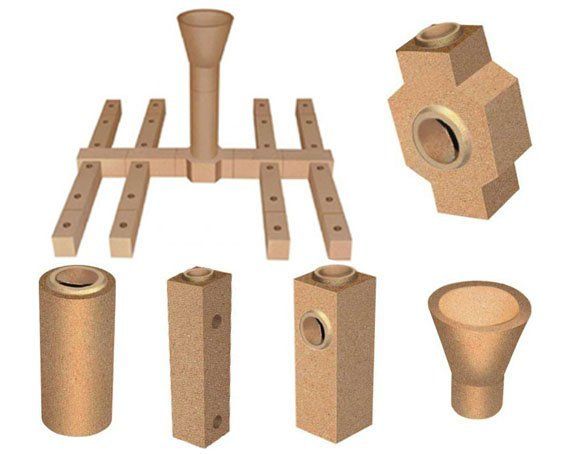

Bottom Pouring Sets

Bottom Pouring Sets are a complete combination set of runner bricks and special hollow shapes for bottom pouring molten metal. These shapes are processed from refractory grog, plastic fire clays and non-plastic clays. The sets consist of the runner bricks which have hollow shape so that it is easy to pour the molten metal. The hollow shapes which you find in every Bottom Pouring Sets are made by using the plastic fire clays or sometimes the non-plastic clay is also put to use.

Exceptional Performance at High Temperatures

Bottom Pouring Sets maintain their strength and structural integrity during continuous operation at temperatures up to 1500C. With a melting point of up to 1700C and high cold crushing strength, they are ideally suited for the critical demands of steel casting and foundry applications. Their resistance to slag attack and abrasion ensures consistent performance over multiple pours.

Versatile Design and Tailor-Made Solutions

Offered in both standard and custom sizes as well as shapes (round, oval, custom), these sets can be adapted to specific bottom pouring system requirements. Their precise construction, dimensional stability, and smooth surface finish support efficient and reliable molten metal transfer, ensuring optimal results in your casting processes.

Reliable Packaging and Export Quality

Each Bottom Pouring Set is securely packed on wooden pallets using export-grade materials to protect against moisture and damage during transit, guaranteeing that products reach international and domestic clients in perfect condition. High purity and well-cured assemblies ensure quality right from installation.

FAQ's of Bottom Pouring Sets:

Q: How are Bottom Pouring Sets installed in steel and foundry applications?

A: Bottom Pouring Sets are assembled using specialized refractory mortar to ensure a secure and stable fit within the bottom pouring system. The process involves precise alignment of components for optimal molten metal flow and minimized leakage during castings.Q: What benefits do these sets offer for multiple pours in steel casting?

A: They provide long service life and high abrasion resistance, enabling reliable operation over multiple pours without frequent replacement. Their resistance to slag attack helps reduce downtime and maintenance in steel and foundry operations.Q: When should I consider using tailor-made Bottom Pouring Sets?

A: Tailor-made sizes and shapes are ideal when your bottom pouring system requires non-standard configurations, or when you seek to optimize compatibility and efficiency for specific casting needs. Customized solutions ensure the best fit and performance for complex projects.Q: Where are these Bottom Pouring Sets manufactured and exported from?

A: These sets are manufactured in India by trusted exporters, manufacturers, and suppliers. Export-quality packaging ensures safe delivery worldwide, maintaining the integrity and performance of the assemblies.Q: What is the process for selecting the right Bottom Pouring Set for my application?

A: Selection depends on your system's compatibility requirements, operating temperature, batch size, and desired shape or dimensions. Consultation with the manufacturer allows you to choose between standard or custom assemblies tailored to your steel or foundry processes.Q: How do these sets contribute to efficiency in bottom pouring operations?

A: Thanks to their low thermal conductivity, high dimensional stability, and smooth surface finish, Bottom Pouring Sets facilitate efficient molten metal transfer, minimizing heat loss and maximizing yield during ingot production.Q: What is the typical usage of Bottom Pouring Sets in the foundry industry?

A: Bottom Pouring Sets are primarily used for controlled pouring of molten metal into ingot molds during steel casting. Their compatibility with major bottom pouring systems and robust construction make them indispensable in foundry operations focused on quality and consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Alumina Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Water Absorption : Low (<1%)

Chemical Composition : Alumina (65%), Magnesia (1525%), Carbon (815%)

Types of Refractories : Basic Refractory

Strength : >40 MPa (Cold Crushing Strength)

Magnesite Bricks

Price Range 2.00 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Water Absorption : < 2%

Chemical Composition : MgO (Magnesium Oxide): 8595%, SiO2: 36%, Fe2O3: 12%

Types of Refractories : Other, Basic Refractories

Strength : Cold Crushing Strength (CCS): 3060 MPa

Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Water Absorption : 0.3%

Chemical Composition : MgO > 70%, C = 1020%

Types of Refractories : Basic Refractory

Strength : Cold Crushing Strength: 2535 MPa

Insulating Fire Bricks

Minimum Order Quantity : 500 Pieces

Water Absorption : 3550%

Chemical Composition : AluminaSilicate

Types of Refractories : Other, Insulating Refractory Brick

Strength : Cold Crushing Strength: 1535 kg/cm

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry