Silicon Carbide Refractories

Silicon Carbide Refractories Specification

- Chemical Composition

- SiC >90%, Fe2O3 <1%, Free SiO2 <1.5%

- Purity(%)

- Above 90%

- Melting Point

- 2700C

- Density

- 2.85 Gram per cubic centimeter(g/cm3)

- Application

- Used in furnaces, kilns, incinerators, and reactors; ideal for non-ferrous metal industries, ceramic, glass, cement, and petrochemical sectors.

- Form

- Solid

- Usage & Applications

- Furnace linings, kiln furniture, crucibles, incinerator linings, and wear-resistant linings.

- Hardness (%)

- Mohs 9.0+

- Surface Finish

- Smooth, Uniform

- Water Absorption

- <1%

- Product Type

- Refractories

- Types of Refractories

- Silicon Carbide (SiC)

- Shape

- Brick, Block, Customized Shapes

- Porosity

- 1318%

- Dimensional Stability

- Excellent at high temperatures

- Strength

- High crushing strength (> 300 MPa) at room temperature

- Specific Gravity

- 2.653.10 g/cm

- Thermal Conductivity

- Excellent (at 1200C: ~1016 W/mK)

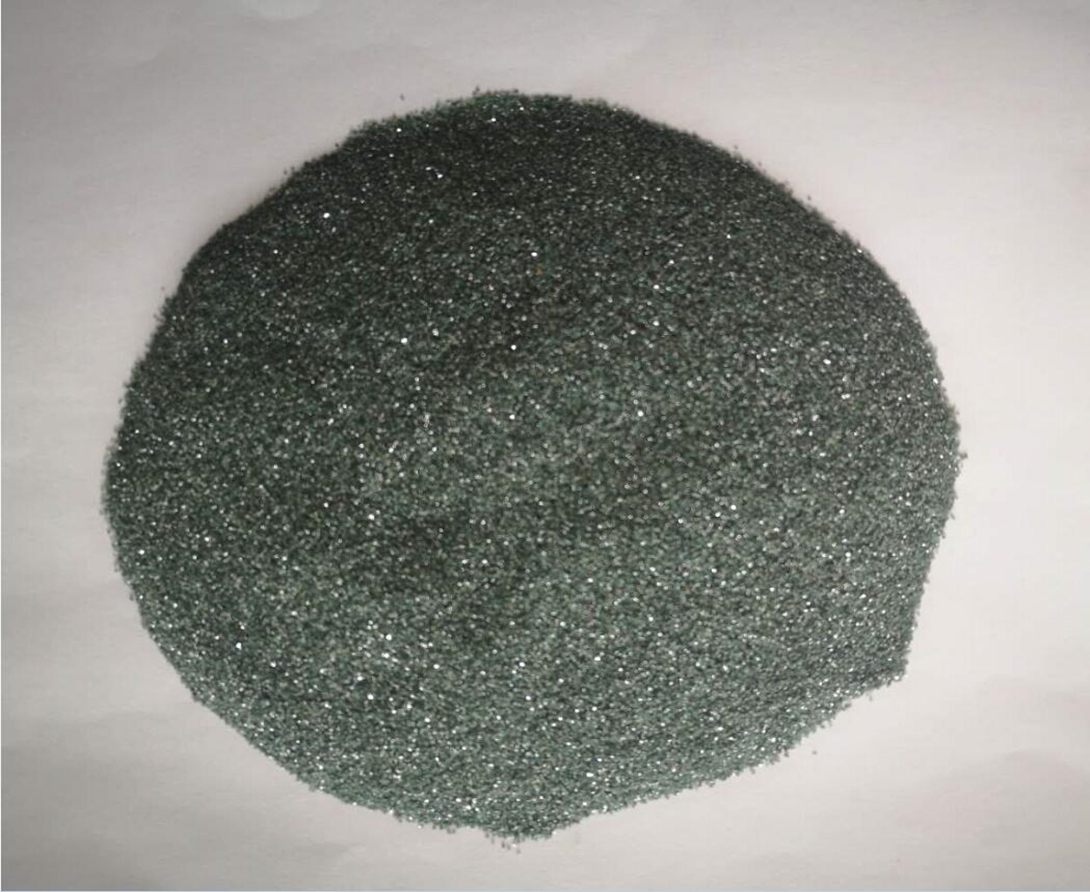

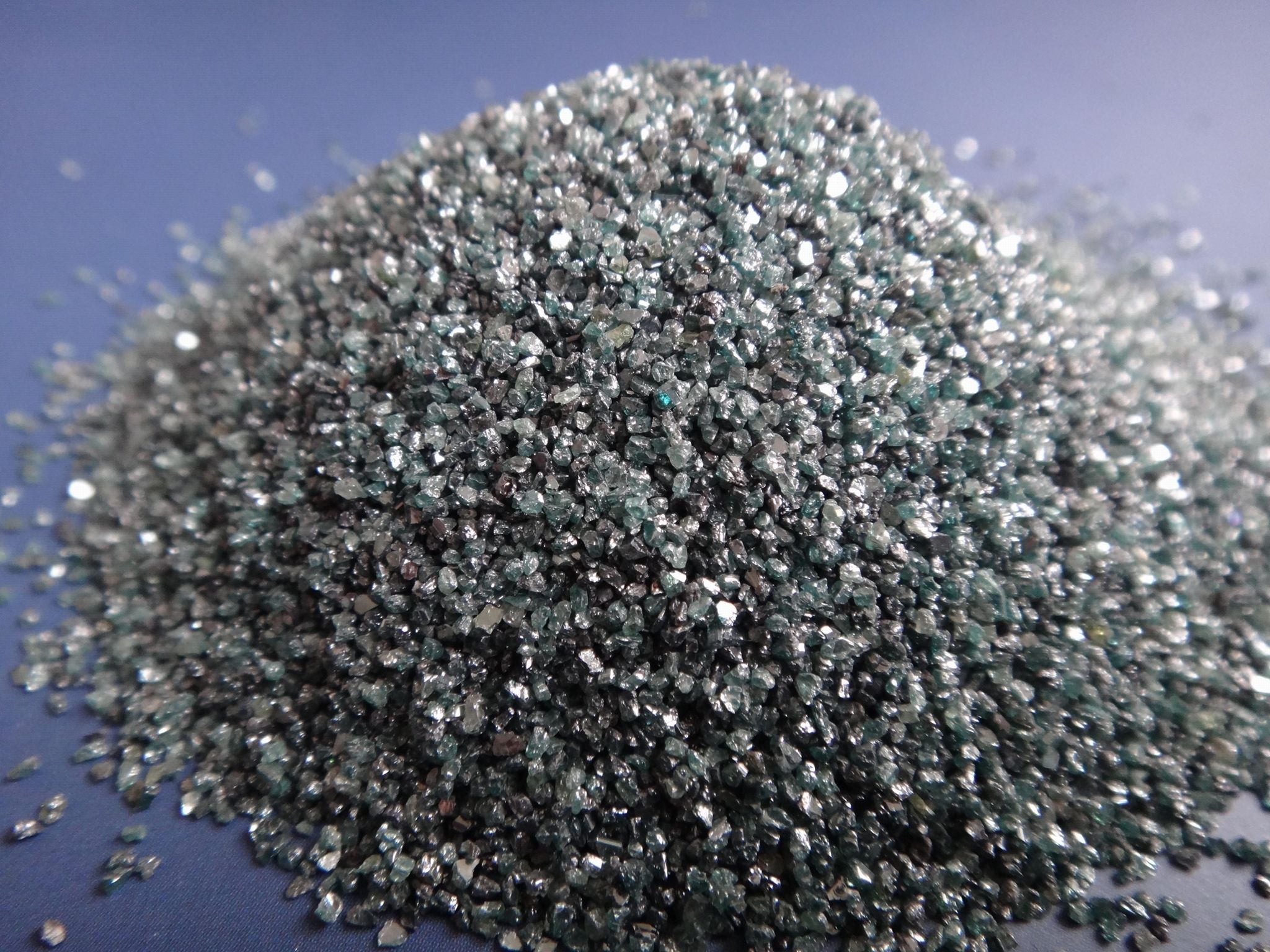

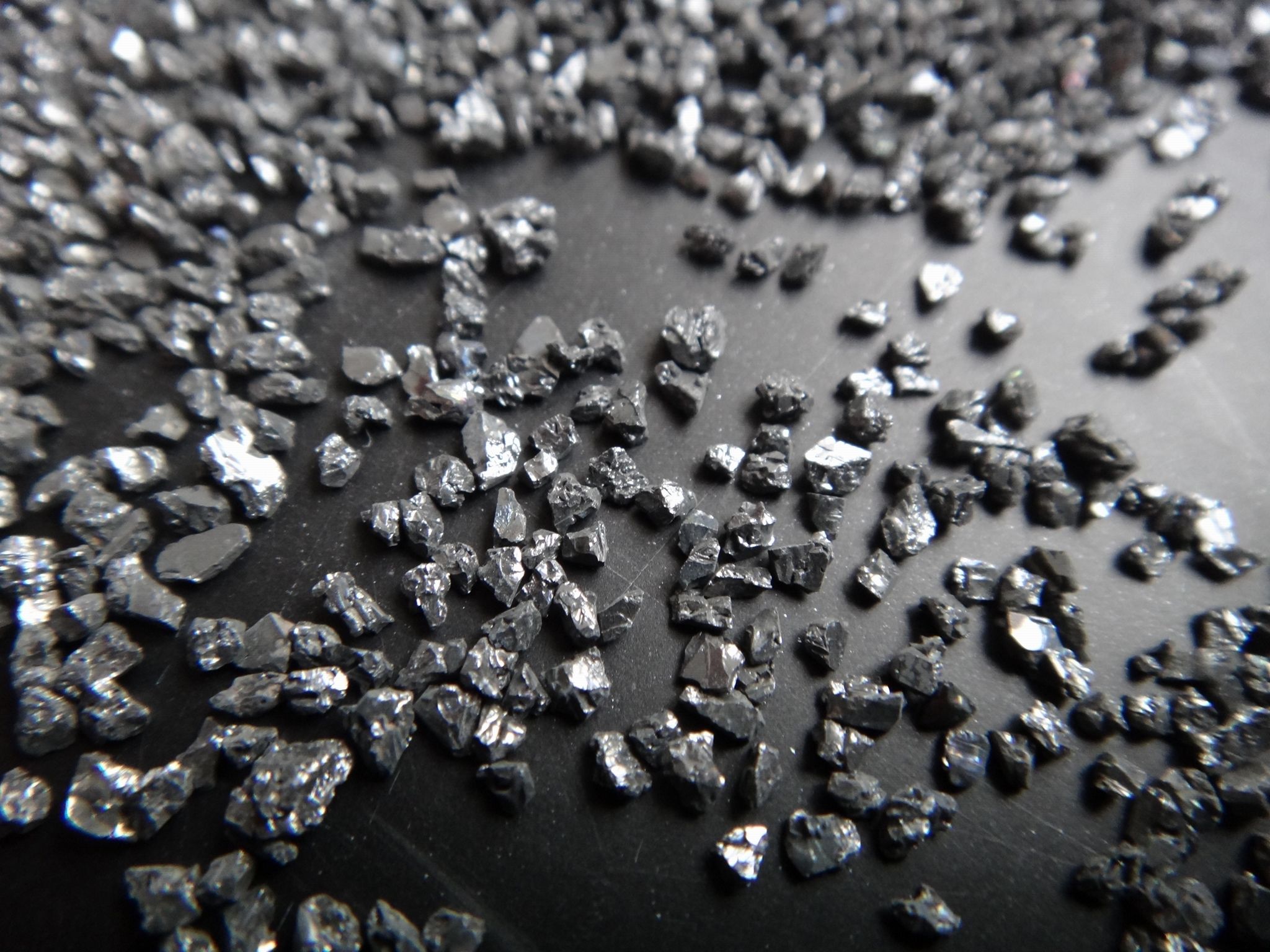

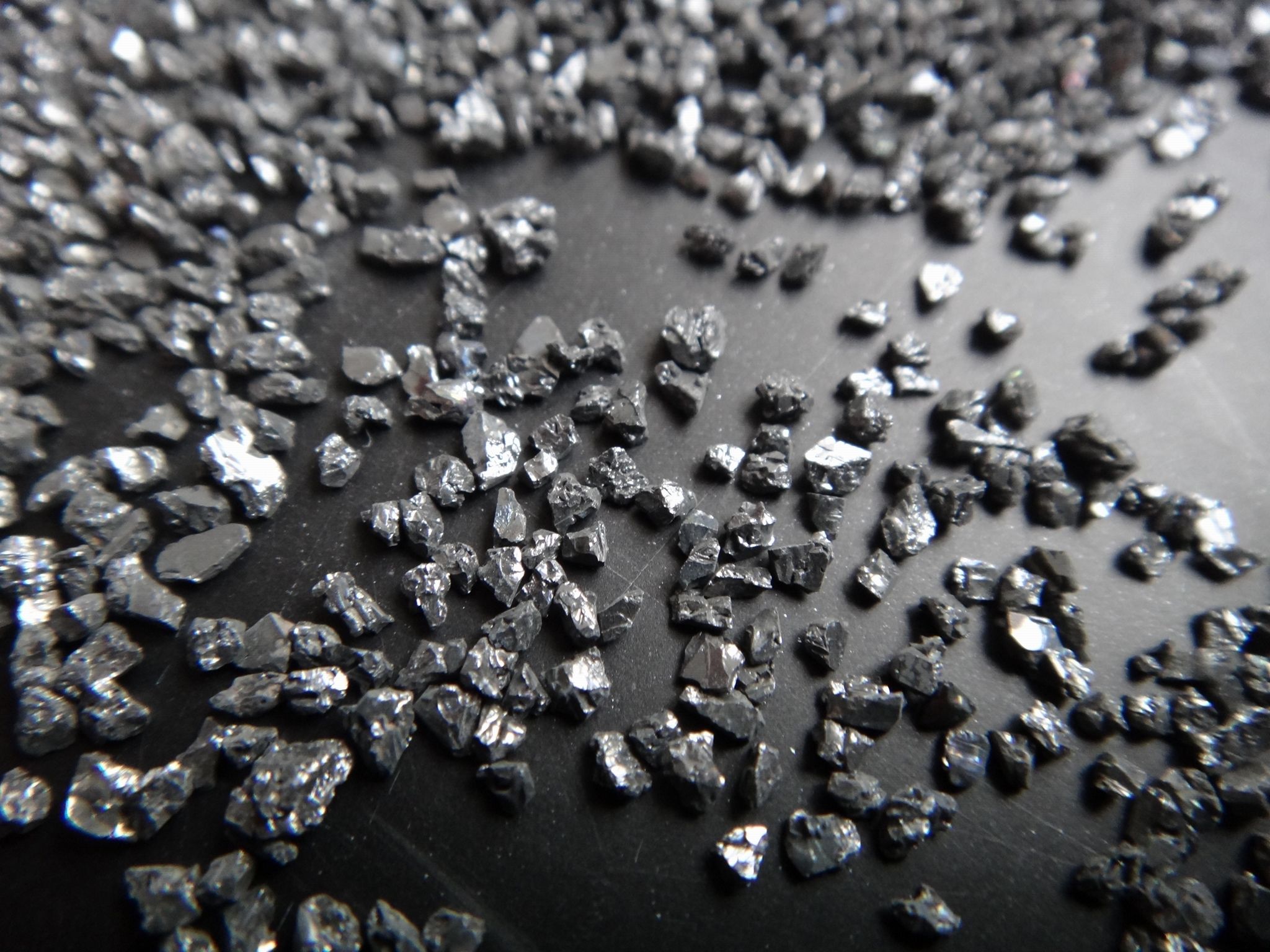

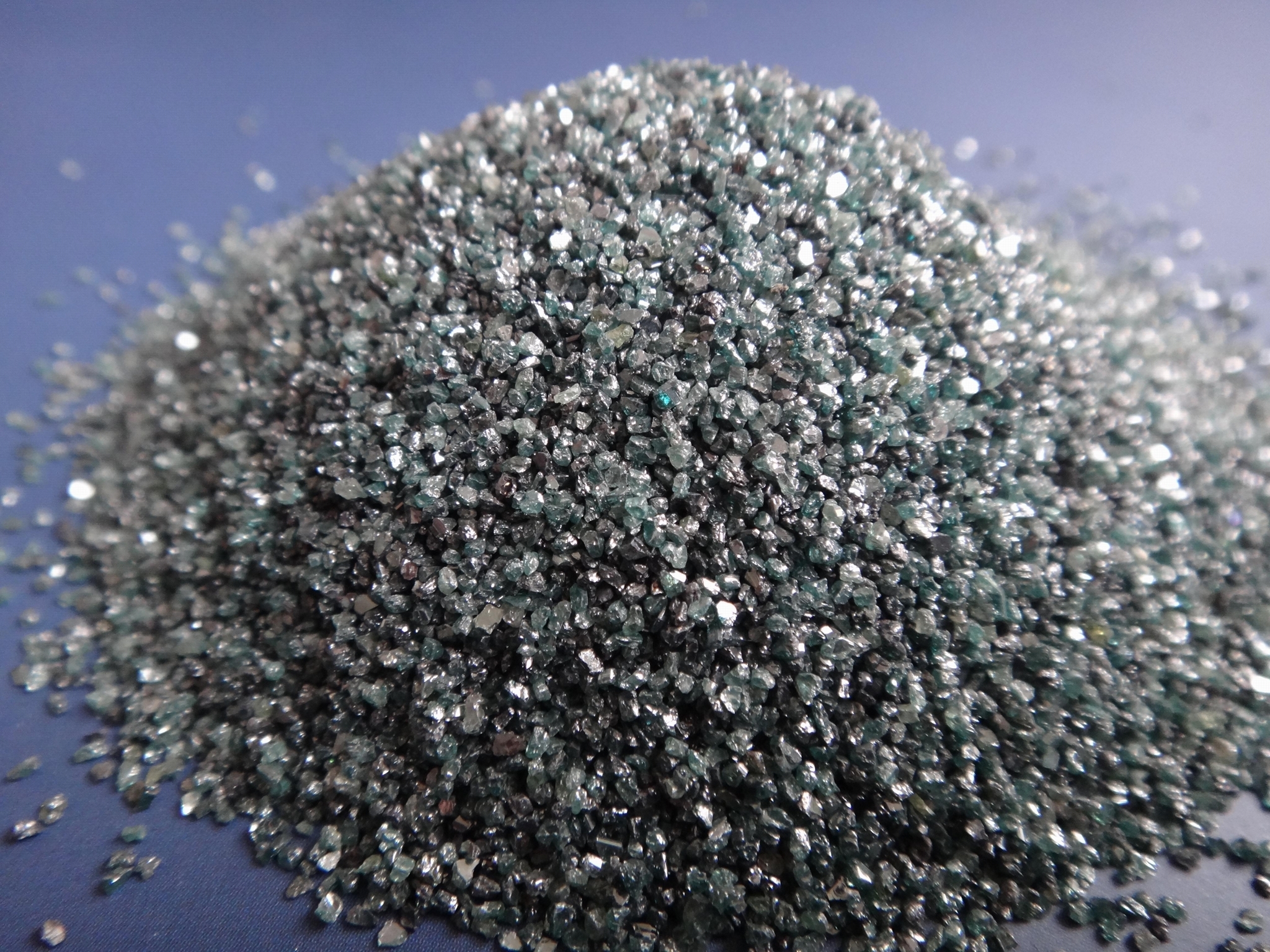

- Color

- Black/Grey

Silicon Carbide Refractories Trade Information

- Minimum Order Quantity

- 20 MT Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Days after Acceptance (DA)

- Supply Ability

- 1000 Metric Tons Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

About Silicon Carbide Refractories

Silicon Carbide Refractories

Silicon carbide is the primary raw material that is processed to produce silicon carbide refractories. This product is produced when silicon and carbon react together. The refractories are chemically inert, resistant to erosion, corrosion and abrasion, and have high thermal conductivity. The industries where these refractories find use are not limited to sanitary ware, electronics, semiconductor, metallurgy, ceramic and more. The main applications include tap hole lining, chamber fronts, kiln furniture, etc.

Superior Thermal and Mechanical Performance

With the ability to withstand rapid temperature fluctuations and intense mechanical loads, Silicon Carbide Refractories offer excellent thermal shock resistance and high bulk modulus. Their dimensional stability and low creep deformation above 1500C make them ideal for extreme environments.

Versatile Shapes and Reliable Quality

These refractories are available in a variety of standard and customized shapes. They feature smooth, uniform surfaces, and each unit is offered with palletized packaging or as required. Compliance with IS and international refractory standards ensures reliability and consistent performance.

Broad Industrial Applications

Silicon Carbide Refractories are utilized in furnace and incinerator linings, kiln furniture, and crucibles. Their high purity, density, and abrasion resistance make them suitable for non-ferrous metal, ceramic, glass, cement, and petrochemical industries.

FAQ's of Silicon Carbide Refractories:

Q: How do Silicon Carbide Refractories resist thermal shock during rapid temperature changes?

A: Their excellent thermal shock resistance stems from stable chemical and physical properties, allowing them to withstand abrupt temperature variations without cracking or spalling, making them suitable for demanding operations such as furnace linings and kiln furniture.Q: What industries commonly use Silicon Carbide Refractories, and why are they preferred?

A: Industries such as non-ferrous metals, ceramics, glass, cement, and petrochemicals favor Silicon Carbide Refractories for their high abrasion resistance, mechanical strength, and reliable performance under high temperatures and oxidizing conditions.Q: When is it recommended to choose Silicon Carbide Refractories over other refractory materials?

A: Silicon Carbide Refractories are recommended when the application involves high temperatures (continuous up to 1800C), rapid temperature shifts, high mechanical loads, or severe abrasion, such as in incinerators, furnaces, and reactors.Q: Where can Silicon Carbide Refractories be installed within an industrial facility?

A: They are typically used in locations demanding durability and thermal stability, such as furnace linings, kiln furniture, crucibles, incinerator linings, and wear-resistant areas within metal, glass, ceramic, and chemical processing plants.Q: What is the process for customizing shapes and sizes of Silicon Carbide Refractories?

A: Manufacturers and suppliers offer standard and customized shapes based on client drawings or specifications. The process involves precise molding and firing, ensuring uniformity, smooth surfaces, and adherence to industry standards for each order.Q: How do Silicon Carbide Refractories benefit overall operational efficiency?

A: Their high resistance to thermal shock, abrasion, and creep deformation ensures prolonged service life, minimal downtime, and reduced maintenance, resulting in improved operational efficiency and cost-effectiveness for industrial facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Basic Refractories Category

Basic Monolithics

Price Range 100.00 - 800.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Thermal Conductivity : Low to Medium

Shape : Other, Monolithic

Form : Powder, Castable, Ramming Mix

Porosity : Low

Refractory Concrete

Price Range 100.00 - 800.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Thermal Conductivity : Low

Shape : Other, Powder or Cast Shapes

Form : Powder / Cast Shape

Porosity : Low

Silicate Cement

Price Range 1350.00 - 1450.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Thermal Conductivity : Low (approx. 0.2 0.25 W/mK)

Shape : Other, Powder/ Paste

Form : Powder / Paste

Porosity : Low

Refractory Cement

Price Range 100.00 - 300.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Thermal Conductivity : Low, approx. 1.2 W/mK

Shape : Other, Powder / Granules

Form : Powder

Porosity : Low

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry