Most Popular Products

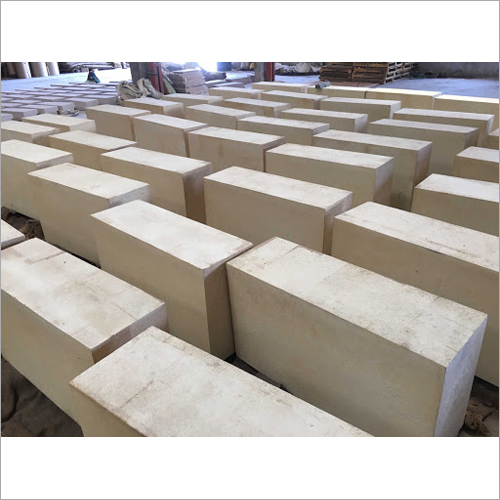

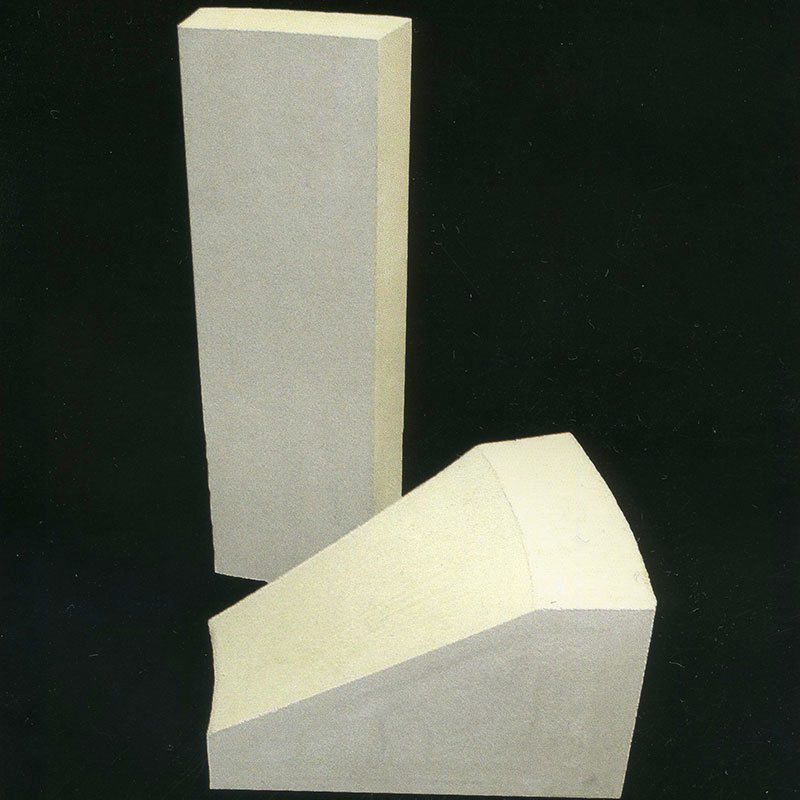

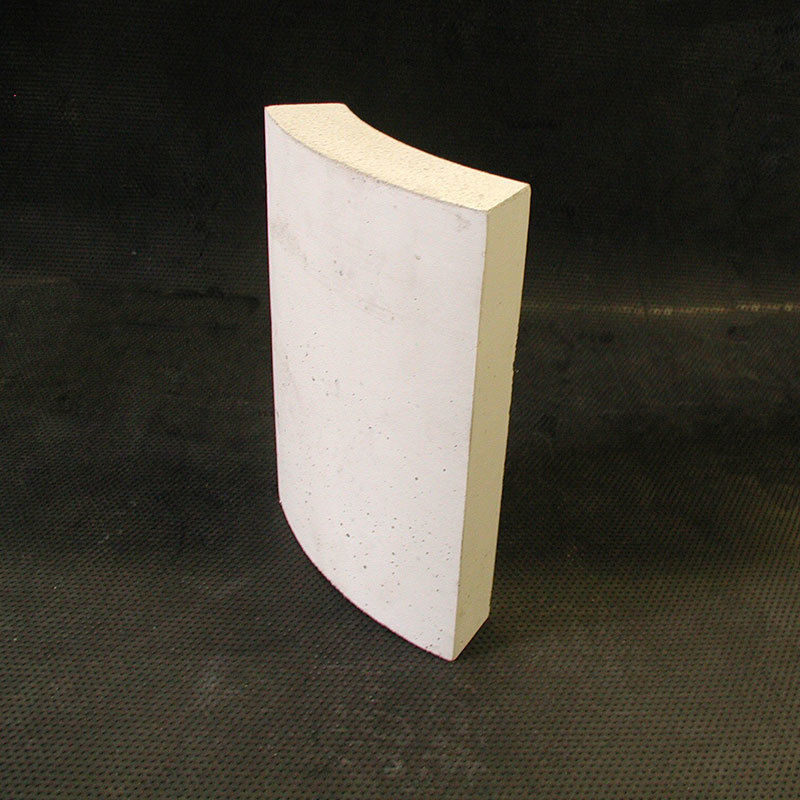

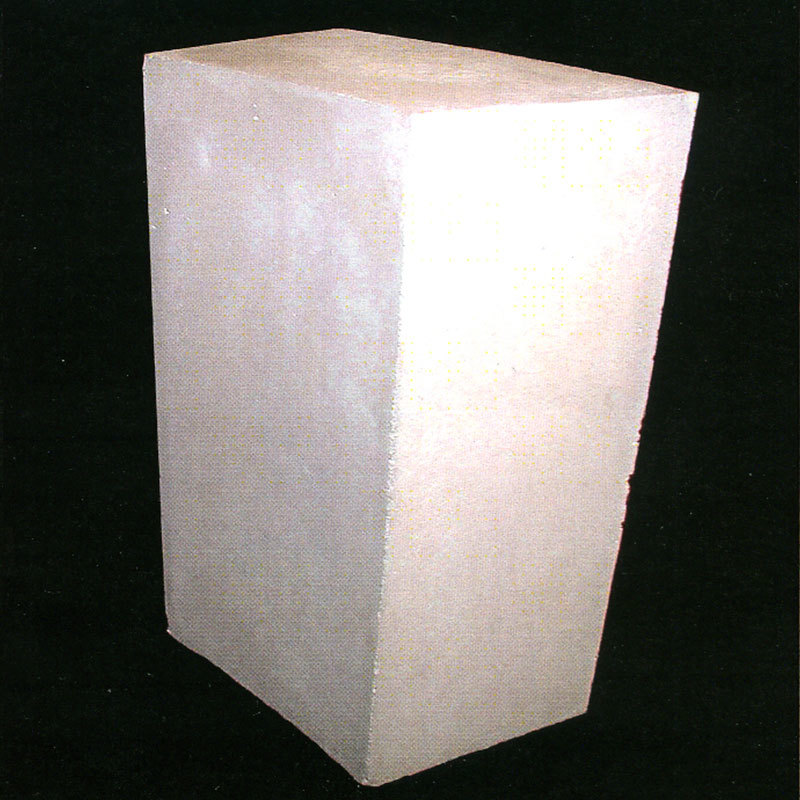

Refractory Tiles

Price 0.15 USD ($)/ Piece

MOQ : 3000 Pieces

Refractory Tiles Specification

- Form

- Solid

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Water Absorption

- <18%

- Application

- Furnace lining, kilns, incinerators, boiler walls, stove lining

- Chemical Composition

- Alumina, Silica, Clay

- Surface Finish

- Smooth

- Purity(%)

- >90%

- Hardness (%)

- >80%

- Usage & Applications

- Industrial furnaces, chimneys, reactors, glass lining, metal melting units

- Melting Point

- Up to 1700C

- Product Type

- Refractories

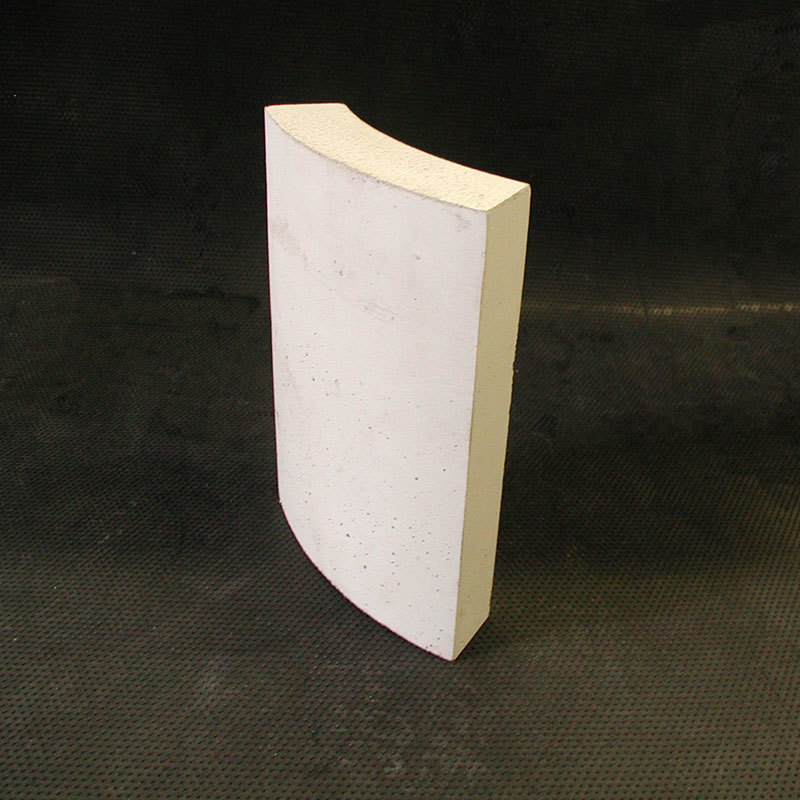

- Types of Refractories

- Acidic, Neutral, Basic

- Shape

- Rectangular, Square and customized

- Porosity

- 18-22%

- Dimensional Stability

- Superior at high temperatures

- Strength

- High cold crushing strength (130-250 kg/cm)

- Specific Gravity

- 2.35 - 2.65

- Thermal Conductivity

- Low (approx. 0.8-1.2 W/mK at 1000C)

- Color

- Light Brown

- Thermal Shock Resistance

- Good to Excellent

- Compressive Strength

- 35-55 MPa

- Modulus of Rupture (MOR)

- >35 kg/cm²

- Abrasion Resistance

- Excellent

- Size Tolerance

- ±2 mm

- Bulk Density

- 1.95 g/cm³

- Storage Condition

- Store in dry covered area to prevent moisture absorption

- Alkali Resistance

- Very High

- Flexural Strength

- 25-40 MPa

- Service Temperature Range

- Up to 1600°C

Refractory Tiles Trade Information

- Minimum Order Quantity

- 3000 Pieces

- FOB Port

- Mundra

- Payment Terms

- Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 30000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Asia, North America, Africa

About Refractory Tiles

Refractory TilesRefractorytiles are a block of refractory ceramic material used in lining furnaceskilns fireboxes and fireplaces They are manufactured with a unique slurrycasting process which creates a network of micro porosities producing lowthermal conductivity and good thermal shock characteristics Their strength isconsistent at room and high temperatures and they provide excellent service inspecial atmospheres in part due to their resistance to alkali Refractory tilesoffered by CMS INDUSTRIES is known for its chemical and physical properties inthe foreign markets

Refractorytiles can be cut to size and are made of a fireclay with the right balance ofsilica and alumina making them an excellent structural insulation materialmade to withstand high temperatures abrasion and chemical attack It isdesigned mainly to withstand high heat but should also usually have a lowthermal conductivity to save energy Bricks have excellent strength at room andhigh temperatures and are particularly good for special atmospheres We are aleading Manufacture Supplier and Exporter of Best Quality of Refractory tilesas per the customers needs and requirements

Superior Performance in Extreme Conditions

With a service temperature range up to 1600C and a melting point of 1700C, these refractory tiles are built to endure intense heat and thermal shocks. Their excellent abrasion and alkali resistance ensure longevity and minimal maintenance in industrial environments, even under cyclical heating and cooling.

Versatile Applications Across Industries

Due to high strength, low porosity, and remarkable dimensional stability, these tiles are suited for furnace linings, chimneys, glass industry units, metal melting plants, boiler walls, stove linings, and reactors. Their adaptability is enhanced by various shapes and customizable dimensions to fulfill diverse project requirements.

Quality Composition for Lasting Durability

Made from high-purity alumina, silica, and clay, our refractory tiles offer a purity level above 90% and a density of 2.3 g/cm3. The low water absorption (<18%) and high hardness (>80%) further protect structural integrity. Store in a dry, covered area to maintain optimal performance during installation.

FAQ's of Refractory Tiles:

Q: How should Refractory Tiles be stored before installation?

A: Refractory Tiles must be kept in a dry, covered environment to prevent moisture absorption, which can compromise their performance and longevity.Q: What processes are used in manufacturing these refractory tiles?

A: These tiles are manufactured from a blend of alumina, silica, and clay, shaped (rectangular, square, or customized), and fired at high temperatures to achieve a high degree of purity, strength, and dimensional stability.Q: When is it recommended to use these tiles in industrial settings?

A: These tiles are ideal for use in situations requiring resistance to high temperatures (up to 1600C), chemical attack, thermal shock, and abrasion-such as furnaces, kilns, and incinerators.Q: Where are refractory tiles most commonly applied?

A: They are extensively used for lining furnaces, chimneys, kilns, incinerators, boiler walls, stove linings, reactors, as well as glass and metal melting units.Q: What benefits do these refractory tiles offer compared to conventional linings?

A: Refractory Tiles provide superior thermal shock resistance, low thermal conductivity, high alkali and abrasion resistance, and extended service life even in aggressive industrial environments.Q: How does the chemical composition affect tile performance?

A: The combination of alumina, silica, and clay imparts high purity, strength, and chemical resistance, making the tiles capable of withstanding both acidic and basic attack as well as providing stability at elevated temperatures.Q: What types of refractory tiles are available for different applications?

A: Tiles are available in acidic, neutral, and basic types, allowing for selection based on the specific chemical environment and requirements of each industrial process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Tiles & Blocks Category

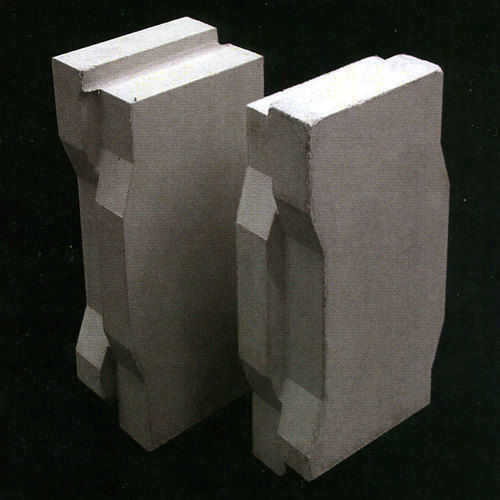

PCPF Blocks

Price Range 40.00 - 95.00 USD ($) / Piece

Minimum Order Quantity : 200 Pieces

Hardness (%) : 60%80%

Dimensional Stability : Other, Excellent at High Temperatures

Purity(%) : 85%98%

Specific Gravity : 1.8 2.3

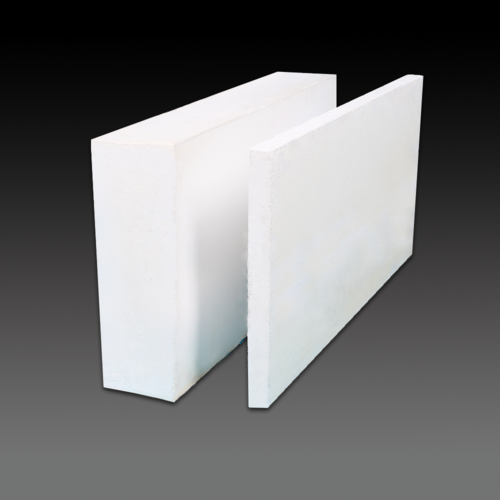

Calcium Silicate Blocks

Price Range 1.50 - 10.00 USD ($) / Piece

Minimum Order Quantity : 200 Pieces

Hardness (%) : High, retains rigidity at high temperatures

Dimensional Stability : Other, Excellent at high temperatures, minimal shrinkage

Purity(%) : >90% (Calcium Silicate content)

Specific Gravity : ~1.2 to 1.5

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry