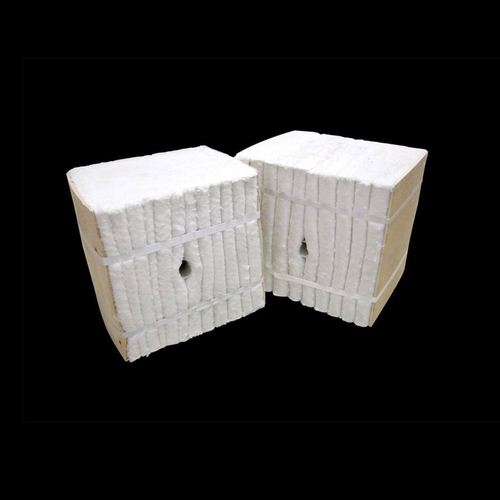

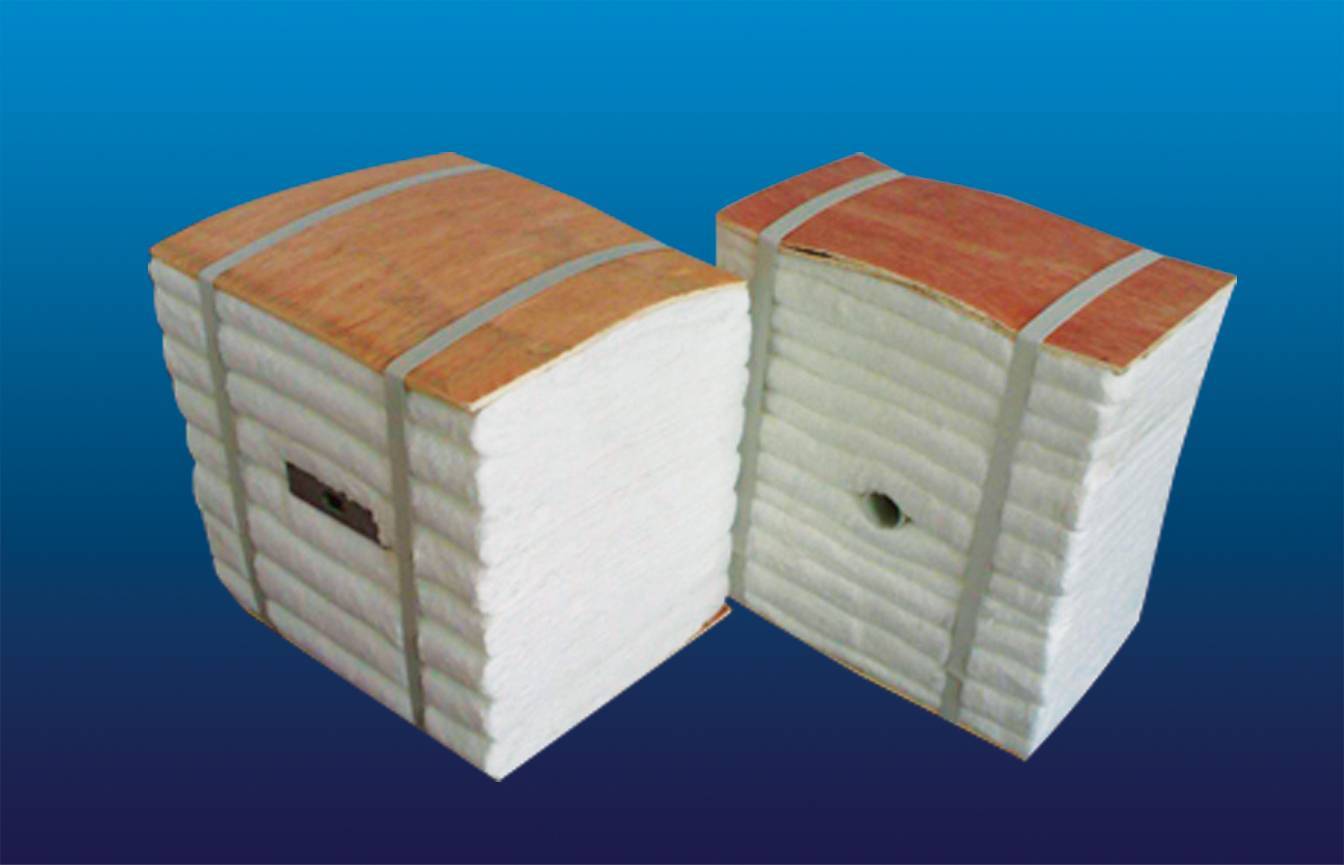

Ceramic Fiber Module

Ceramic Fiber Module Specification

- Purity(%)

- >96%

- Application

- Kiln lining, Furnace insulation, Boiler insulation, Petrochemical, Power Generation

- Melting Point

- >1790C

- Density

- 180 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Al2O3, SiO2 (Alumina-silica based)

- Water Absorption

- Nil

- Form

- Modular Block

- Surface Finish

- Smooth, fiber-textured

- Usage & Applications

- Used in lining of industrial furnaces, kilns, and other thermal equipment

- Product Type

- Refractories

- Types of Refractories

- Acidic Refractories

- Shape

- Rectangular module, folded

- Porosity

- 45-55%

- Dimensional Stability

- Excellent dimensional stability at high temperatures

- Strength

- High compressive strength

- Specific Gravity

- ~2.6 g/cm

- Thermal Conductivity

- Low, typically 0.16-0.20 W/mK at 800C

- Color

- White

- Installation

- Anchored Type, Easy Mechanical Fixing

- Thermal Shock Resistance

- Excellent

- Environmental Safety

- Asbestos Free, Non-Toxic

- Heat Storage

- Low

- Classification Temperature

- 1260°C, 1350°C, 1430°C

- Sound Absorption

- Good

- Module Sizes Available

- 300x300x300 mm, 300x300x250 mm, Custom Sizes

- Service Temperature

- Up to 1400°C

Ceramic Fiber Module Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Western Union, Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

About Ceramic Fiber Module

Ceramic Fiber Module

Ceramicfiber module has excellent refractory, energy saving and insulating effects,and low heat storage. It improves the refractory and insulating integrity offurnaces and improves furnace construction process. It can be directly fixed onthe shell of the industrial furnace; installation is fast and easy. CMS INDUSTRIESis one of the leading manufacturers, suppliers and exporters of Ceramic FiberModule, which are known for their superior quality and for varied customizedfeatures.

Ceramicfiber module has its main properties they are low heat storage, faster insulation,superior to thermal stability, shock resistance, reduced shrinkage and goodsound absorption. Ceramic fiber modules are made from high quality needledBlanket, Edge staked (or) Folded with various anchors and other accessories toenable quick, convenient and efficient installation in most furnace linings.These prefabricated modules are designed to meet the thermal insulationrequirements of high temperature furnaces.

Superior Performance in Extreme Heat

Engineered for service up to 1400C, these ceramic fiber modules maintain their integrity and insulating power under the toughest industrial conditions. Their alumina-silica composition ensures low thermal conductivity and outstanding resistance to thermal shock, making them ideal for applications with rapid temperature variations.

Effortless Installation and Customization

Available in standard and custom sizes, our modules feature an anchored mechanical fixing system for quick and accurate placement. Their modular, folded design offers flexibility, adaptability to various furnace shapes, and straightforward maintenance or replacement.

Safe, Eco-friendly Material

These modules are entirely asbestos-free and non-toxic, prioritizing environmental safety and occupational health. Their high purity and absence of hazardous substances make them a secure choice for diverse industrial insulation needs.

FAQs of Ceramic Fiber Module:

Q: How are ceramic fiber modules installed in industrial furnaces?

A: Ceramic fiber modules are typically installed using an anchored mechanical fixing system, which secures each module to the furnace lining. This ensures a tight fit, excellent thermal insulation, and ease of installation or replacement.Q: What benefits do ceramic fiber modules offer over conventional insulation materials?

A: These modules provide low thermal conductivity, excellent thermal shock resistance, minimal heat storage, and high compressive strength. Their asbestos-free composition ensures environmental safety while delivering superior insulation and energy savings.Q: When should ceramic fiber modules be considered for kiln or furnace lining?

A: Ceramic fiber modules are recommended when high temperatures (up to 1400C), rapid thermal cycling, and strict energy efficiency are required, especially in kilns, industrial furnaces, boilers, petrochemical, or power generation equipment.Q: Where can these modules be used aside from industrial furnaces?

A: Apart from furnace and kiln linings, ceramic fiber modules are suitable for boilers, petrochemical processes, power generation plants, and other thermal equipment needing reliable high-temperature insulation.Q: What is the process for ordering custom-sized ceramic fiber modules?

A: To order custom sizes, specify the required dimensions and application details to the manufacturer or supplier. They will design and fabricate modules tailored to your equipments geometry, ensuring optimal fit and performance.Q: How does the modules chemical composition affect its performance?

A: The modules are made from high-purity alumina-silica fibers (Al2O3 and SiO2), which provide excellent dimensional stability, chemical resistance, and performance even at extreme temperatures, ensuring longevity and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ceramics Fiber Category

Cerawool Blanket

Price Range 100.00 - 1000.00 USD ($) / Cubic Meter

Minimum Order Quantity : 50 Cubic Meters

Surface Finish : Smooth and flexible

Hardness (%) : Soft (Nonrigid)

Form : Flexible blanket

Strength : Excellent tensile strength

Ceramic Fiber Board

Price Range 5.00 - 15.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Surface Finish : Smooth, Rigid Surface

Hardness (%) : Up to 60%

Form : Solid Board

Strength : Good compressive & flexural strength

Ceramic Fiber Cloth

Price Range 5.40 - 10.00 USD ($) / Kilograms

Minimum Order Quantity : 1500 Kilograms

Surface Finish : Soft, woven

Hardness (%) : 6070%

Form : Flexible cloth sheets

Strength : High tensile strength

Ceramic Fiber Rope

Minimum Order Quantity : 1500 Pieces

Surface Finish : Textile, ropelike

Hardness (%) : N/A (Flexible material)

Form : Braided or twisted rope

Strength : High tensile strength, good flexibility

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry