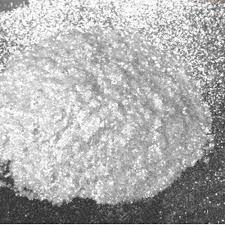

Mica Coarse Powder

Mica Coarse Powder Specification

- Application

- Paints ,Ceramics ,Rubber , Linoleum Flooring

- Product Type

- Minerals

Mica Coarse Powder Trade Information

- Minimum Order Quantity

- 27 Metric Tons

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Delivery Time

- 5 Days

- Packaging Details

- WE PROVIDE 25KG, 50KG PP BAGS, WE ALSO PROVIDE CUSTOMIZED PACKAGING AND PRINTING OPTIONS IN ALL SIZES

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, Eastern Europe, Middle East, Central America, South America, Africa

About Mica Coarse Powder

Versatile Applications in Multiple Industries

Mica Coarse Powder's unique properties make it indispensable in various fields. Its high heat resistance and insulating capabilities enhance paints, ceramics, rubber compounds, and linoleum flooring. The grayish silver color and pearlescent luster improve both performance and appearance. The coarse, rough powder form with irregular flakes is ideal for blending into industrial materials, offering reliability across diverse manufacturing settings.

Quality Assurance and Sourcing from India

As an exporter, manufacturer, and supplier based in India, quality remains a priority. The low moisture content and controlled bulk density prevent caking and ensure consistent product flow. Each batch undergoes thorough quality checks, ensuring it meets industry standards for stability, safety, and effectiveness in end-use applications such as paints and ceramics.

FAQ's of Mica Coarse Powder:

Q: How is mica coarse powder produced and processed to maintain its properties?

A: Mica coarse powder is produced by carefully crushing and grinding mica blocks to achieve coarse granules with irregular flakes and rough texture. Strict control during manufacturing preserves its low moisture content and maintains the natural pearlescent luster, heat resistance, and excellent insulating qualities.Q: What are the main benefits of using mica coarse powder in paints, ceramics, rubber, and flooring?

A: Mica coarse powder enhances products by providing high heat resistance, superior electrical insulation, and improved durability. Its rough, flaky nature adds texture and strength, while its grayish silver, pearlescent appearance contributes to aesthetic appeal, especially in paints and ceramics.Q: When should mica coarse powder be added during manufacturing processes?

A: Mica coarse powder is typically introduced during the mixing or compounding stage of production in paints, ceramics, rubber, and flooring. Early integration ensures even dispersion, allowing its thermal and insulating features to fully benefit the finished product.Q: Where is your mica coarse powder sourced from, and how is quality ensured?

A: Our mica coarse powder is sourced and processed in India, where we maintain strict quality control measures. Each batch undergoes regular testing for particle size, moisture content, bulk density, and insulating properties, ensuring compliance with industry specifications.Q: How is mica coarse powder used in linoleum flooring production?

A: In linoleum flooring manufacturing, mica coarse powder is added to the mixture to improve dimensional stability, enhance heat resistance, and provide a consistent finish. Its insulating attributes and texture also help boost the product's durability and visual appeal.Q: What makes mica coarse powder suitable for high-performance applications?

A: The combination of good heat resistance, high insulating properties, and robust flake structure makes mica coarse powder ideal for demanding applications. Its low moisture content and medium bulk density contribute to reliable performance under various processing conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Minerals Category

Calcined Bauxite

Price Range 100.00 - 500.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Application : Abrasives, Refractories, Sand Blasting, Road Surfacing, Steel Plants, Furnace Linings

Product Type : Refractories

Shape : Other, Grains, Powder, Lumps

Usage & Applications : Steel, Cement, Glass Industries, Road Construction

Basic Ramming Mass

Price Range 90.00 - 250.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Application : Steel Industry, Furnace Lining, Iron and Steel Melting

Product Type : Refractories

Shape : Other, Granule / Powder

Usage & Applications : Used for lining of induction furnaces and foundries

Quartz Grits

Minimum Order Quantity : 25 Metric Tons

Application : Glass manufacturing, foundry, water filtration, construction, abrasive, ceramics, paint

Product Type : Other, Industrial Mineral / Granular Quartz

Shape : Other, Angular or rounded grits

Usage & Applications : Valve castings, epoxy flooring, water treatment, sand blasting, ceramics, construction

Attapulgite Powder API 13A Section 12

Price Range 140.00 - 390.00 USD ($) / Metric Ton

Minimum Order Quantity : 1000 Metric Tons

Application : Industrial, medicinal, thixotrope for coatings, adhesives, paint fertilizers, industrial absorbents

Product Type : Minerals

Shape : Powder

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry