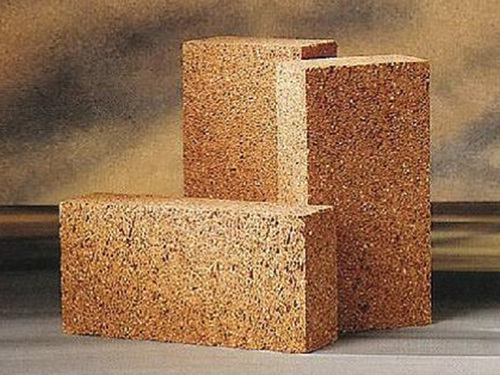

Magnesite Bricks

Magnesite Bricks Specification

- Usage & Applications

- Furnace Lining, Kilns, Regenerators

- Surface Finish

- Smooth

- Melting Point

- Approximately 2800C

- Chemical Composition

- MgO (Magnesium Oxide): 85-95%, SiO2: 3-6%, Fe2O3: 1-2%

- Density

- 3.0 Gram per cubic centimeter(g/cm3)

- Form

- Solid Bricks

- Hardness (%)

- Above 95%

- Application

- Lining of steel making furnaces, non-ferrous metal furnaces, and glass tank regenerators

- Water Absorption

- < 2%

- Purity(%)

- 85% to 95%

- Product Type

- Refractories

- Types of Refractories

- Basic Refractories

- Shape

- Rectangular, customized

- Porosity

- 15-18%

- Dimensional Stability

- Excellent at high temperature

- Strength

- Cold Crushing Strength (CCS): 30-60 MPa

- Specific Gravity

- 2.8-3.0

- Thermal Conductivity

- 3.04.5 W/mK at 1000C

- Color

- Light brown to yellow

Magnesite Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C), Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

About Magnesite Bricks

Magnesite Bricks also called magnesia bricks, magnesium bricks, magnesite refractory bricks and magnesite fire brick. It is one of the most widely used basic refractory bricks. Magnesite Bricks belong to magnesite refractories and contain magnesium oxide content more than 90%. We are a leading Manufacture, Supplier and Exporter of Best Quality of Magnesite Bricks as per the customer's needs and requirements.

Superior Thermal and Mechanical Properties

Magnesite Bricks are distinguished by their high melting point (approximately 2800C) and good thermal shock resistance. Their chemical composition, predominated by high-purity MgO (85-95%), ensures durability and longevity under intense heat and pressure. These bricks demonstrate stable thermal conductivity (3.0-4.5 W/mK at 1000C) and excellent dimensional stability for demanding furnace applications.

Manufacturing and Quality Assurance

Produced via advanced high-temperature sintering processes, Magnesite Bricks from India maintain consistent quality and strength. ISO 9001:2015 certification affirms rigorous production standards. Finished with a smooth surface and low water absorption (<2%), these bricks meet stringent requirements for industrial refractory applications.

FAQ's of Magnesite Bricks:

Q: How are Magnesite Bricks manufactured for optimal performance in aggressive environments?

A: Magnesite Bricks are produced using a high-temperature sintering process, which enhances their density, strength, and slag resistance. This process ensures the bricks exhibit excellent stability and durability when used for lining furnaces exposed to intense heat and corrosive slag.Q: What makes Magnesite Bricks suitable for furnace lining in steel making and non-ferrous industries?

A: Their high refractoriness under load (RUL above 1550C at 0.2 MPa), bulk density, and excellent resistance to basic slags make Magnesite Bricks ideal for protecting furnace linings in steel-making, non-ferrous metal processing, and glass tank regenerators.Q: When should Magnesite Bricks be used in industrial applications?

A: Magnesite Bricks are best employed in environments requiring high thermal and mechanical stability, such as steel furnaces, kilns, and glass regenerators. Their long service life and resistance to wear and chemical attack ensure reliability in continuous high-temperature operations.Q: Where can customized sizes of Magnesite Bricks be sourced from?

A: Customized and standard sizes of Magnesite Bricks can be obtained from manufacturers, suppliers, and exporters based in India. Brick dimensions are tailored to meet specific customer requirements for various furnace configurations.Q: What benefits do Magnesite Bricks offer over other refractory types?

A: Magnesite Bricks provide superior slag resistance, high melting points (approx. 2800C), and excellent dimensional stability at elevated temperatures. These advantages result in prolonged service life and reduced maintenance for industrial furnace linings.Q: How do Magnesite Bricks contribute to thermal efficiency in furnaces?

A: The bricks' stable thermal conductivity (3.0-4.5 W/mK at 1000C) helps maintain uniform heat distribution within furnaces, enabling energy-efficient operations and consistent product quality during high-temperature processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Alumina Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Chemical Composition : Alumina (65%), Magnesia (1525%), Carbon (815%)

Density : 3.10 Gram per cubic centimeter(g/cm3)

Form : Solid/Brick

Hardness (%) : 85 95%

Insulation Bricks

Price Range 1.00 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Chemical Composition : Al2O3 (Alumina), SiO2 (Silica)

Density : 1100 Gram per cubic centimeter(g/cm3)

Form : Solid

Hardness (%) : 5060%

Cupola Bricks

Price Range 0.20 - 0.50 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Chemical Composition : High Alumina, Silica, Magnesia

Density : 2100 Gram per cubic centimeter(g/cm3)

Form : Solid Brick

Hardness (%) : >80%

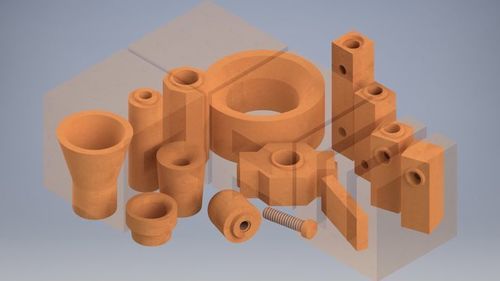

Bottom Pouring Sets

Price Range 40.00 - 160.00 USD ($) / Metric Ton

Minimum Order Quantity : 400 Metric Tons

Chemical Composition : Al2O3, SiO2, CaO, Fe2O3; AluminoSilicates

Density : 2.3 Gram per cubic centimeter(g/cm3)

Form : Sets/Built assemblies

Hardness (%) : Approx. 65% 70%

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry