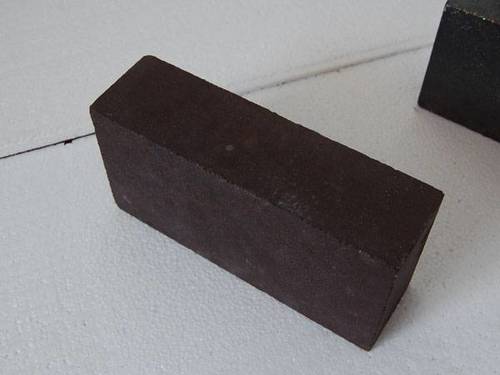

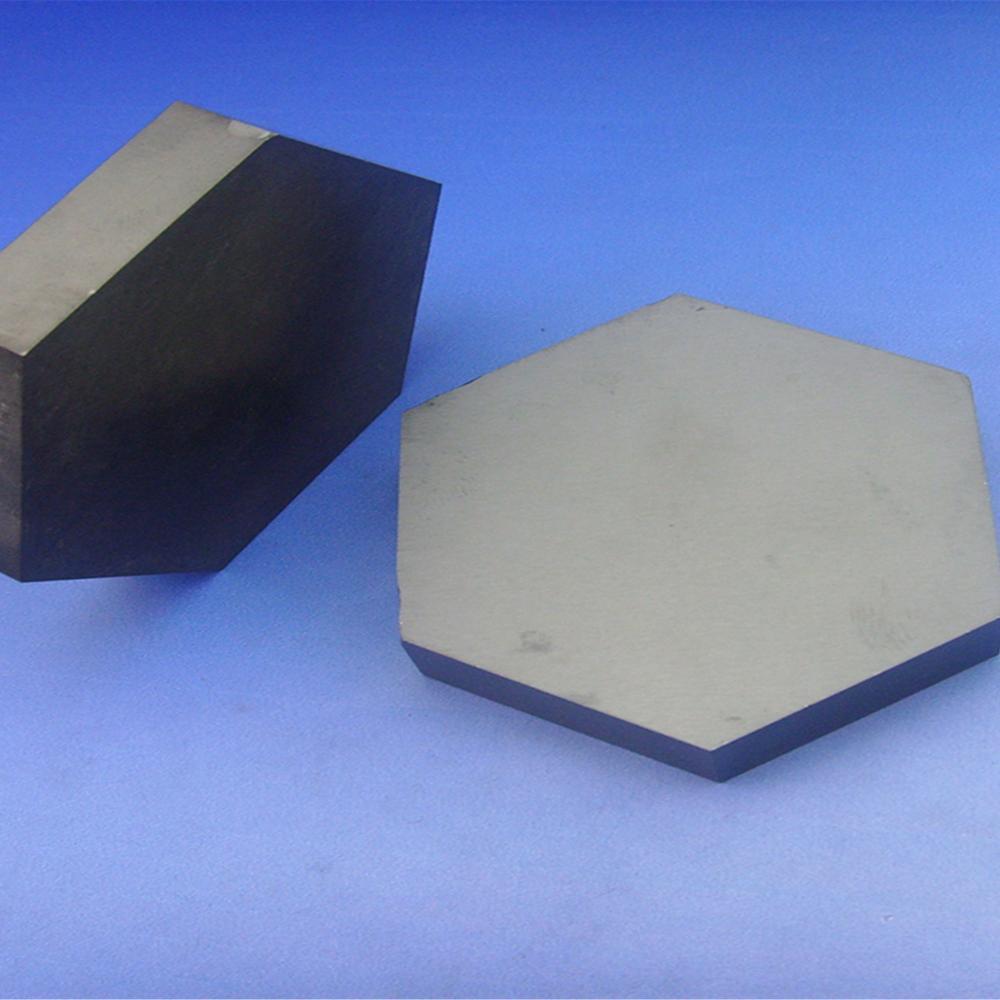

Silicon Carbide Brick

Silicon Carbide Brick Specification

- Purity(%)

- 98%

- Hardness (%)

- Mohs hardness 9

- Surface Finish

- Smooth, uniform

- Density

- 2.75 Gram per cubic centimeter(g/cm3)

- Application

- High temperature furnaces, Kiln furniture, Incinerators, Foundry lining, Metal melting

- Form

- Solid brick, standard & custom sizes

- Water Absorption

- <0.5%

- Usage & Applications

- Lining of kilns & furnaces, heat exchangers, boilers, power plants

- Melting Point

- 2200C - 2400C

- Chemical Composition

- Silicon Carbide (SiC), minor binders

- Product Type

- Refractories

- Types of Refractories

- High alumina, oxide-bonded, nitride-bonded

- Shape

- Rectangular, customized

- Porosity

- 14 18%

- Dimensional Stability

- Excellent at high temperatures

- Strength

- Cold Crushing Strength 50 MPa

- Specific Gravity

- 2.6 2.75 g/cm

- Thermal Conductivity

- High (10 16 W/mK)

- Color

- Black / Grey

- Service Life

- Long

- Refractoriness Under Load (RUL)

- >1700°C

- Size

- 230x115x65 mm or as customized

- Apparent Porosity

- 15-20%

- Oxidation Resistance

- High

- Thermal Shock Resistance

- Very Good

- Bulk Density

- 2.6-2.8 g/cm³

- Abrasion Resistance

- Excellent

- Flexural Strength

- 10-12 MPa

Silicon Carbide Brick Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

About Silicon Carbide Brick

Silicon carbide brick is also known as silicon carbide refractory brick or silicon carbide firebrick. It is made of high quality synthetically made silicon carbide grains (SiC) and selected bonding components, including nitride, Si3N4.They are widely used as lining bricks of large aluminum electrolytic cell. Silicon carbide brick offered by CMS INDUSTRIES is known for its chemical and physical properties in the foreign markets.

Superior Performance in Extreme Conditions

Silicon Carbide Brick delivers exceptional thermal and mechanical properties, ensuring reliable service in the harshest industrial settings. With its high refractoriness under load (>1700C) and excellent resistance to abrasion, oxidation, and rapid thermal change, this brick is designed to maximize operational longevity and safety in furnaces, kilns, and foundries.

Customized Solutions for Diverse Applications

Offered in both standard and tailored shapes and sizes, Silicon Carbide Brick is adaptable for various industries including metal melting, power plants, and heat exchangers. Its precise engineering accommodates custom requirements while maintaining high integrity and performance across different processes, serving as the backbone of modern refractory solutions.

FAQs of Silicon Carbide Brick:

Q: How is Silicon Carbide Brick used in industrial applications?

A: Silicon Carbide Brick is primarily utilized as a lining material in high temperature environments like furnaces, kilns, incinerators, heat exchangers, and foundries. Its outstanding thermal shock and abrasion resistance make it ideal for continuous exposure to extreme heat and mechanical stress, ensuring minimal maintenance and extended service life.Q: What are the primary benefits of using Silicon Carbide Brick?

A: The key benefits include excellent thermal conductivity, very low water absorption (<0.5%), high mechanical strength, superior resistance to oxidation and abrasion, and remarkable longevity at temperatures up to 2400C. Its stability under thermal cycling ensures consistent performance, reducing operational downtime and repair costs.Q: When should I choose Silicon Carbide Brick over other refractory materials?

A: Silicon Carbide Brick is best chosen when applications demand high refractoriness under load, frequent thermal shocks, or exposure to abrasive or corrosive environments. Its superior hardness (Mohs 9) and high purity ( 98%) make it particularly suited for demanding industries where other refractories may deteriorate quickly.Q: Where can Silicon Carbide Bricks be installed?

A: These bricks are ideal for installation in the hot zones of industrial furnaces, kilns, metal melting pots, incinerators, and areas exposed to direct flame or high heat transfer like boiler linings. Their adaptability in size and shape allows them to fit a wide range of designs specified by manufacturers.Q: What is the manufacturing process of Silicon Carbide Brick?

A: Silicon Carbide Bricks are manufactured by forming SiC grains, combined with minor binders, into bricks under high pressure. The bricks are then fired at very high temperatures, resulting in a solid, dense product with a smooth, uniform finish and very low porosity. Custom shapes and sizes can be produced according to client requirements.Q: Can the size and shape of Silicon Carbide Brick be customized?

A: Yes, in addition to the standard size of 230x115x65 mm, these bricks can be customized to specific dimensions or shapes to meet the requirements of unique furnace designs or industrial processes, thereby allowing flexible integration into new or existing systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Cupola Bricks

Price Range 0.20 - 0.50 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Density : 2100 Gram per cubic centimeter(g/cm3)

Application : Cupola Furnace Lining, Foundry Furnaces, Metallurgical Industry

Strength : Cold Crushing Strength >350 kg/cm

Specific Gravity : 2.3 2.6

Alumina Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Density : 3.10 Gram per cubic centimeter(g/cm3)

Application : Steel Industry, Ladle Lining, EAF Roof and Side Walls

Strength : >40 MPa (Cold Crushing Strength)

Specific Gravity : 2.80 3.10 g/cm

Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Density : 3.1 Gram per cubic centimeter(g/cm3)

Application : Steel making furnaces, ladles, converters, EAF lining

Strength : Cold Crushing Strength: 2535 MPa

Specific Gravity : 2.9 3.0

Fire Bricks

Price Range 1.00 - 2.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Density : 2.0 Gram per cubic centimeter(g/cm3)

Application : Furnaces, Kilns, Fireplaces, Lining of Boilers, High Temperature Construction

Strength : Cold Crushing Strength: 3545 MPa

Specific Gravity : 2.1 2.4

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry