Alumina Magnesia Carbon Bricks

Alumina Magnesia Carbon Bricks Specification

- Application

- Steel Industry, Ladle Lining, EAF Roof and Side Walls

- Water Absorption

- Low (<1%)

- Purity(%)

- 98%

- Usage & Applications

- Ladle Lining, EAF, Steel Making Furnaces

- Hardness (%)

- 85 95%

- Chemical Composition

- Alumina (65%), Magnesia (15-25%), Carbon (8-15%)

- Surface Finish

- Smooth

- Density

- 3.10 Gram per cubic centimeter(g/cm3)

- Melting Point

- 1800-1900C approx.

- Form

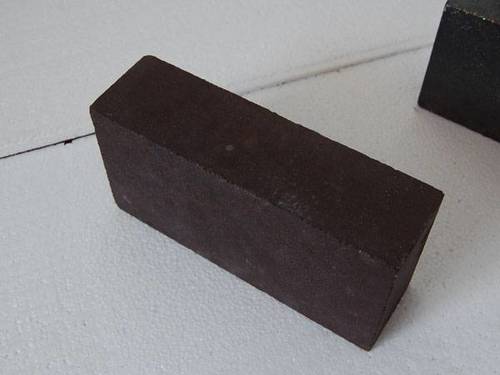

- Solid/Brick

- Product Type

- Refractories

- Types of Refractories

- Basic Refractory

- Shape

- Rectangular, Custom shapes

- Porosity

- 8 - 12%

- Dimensional Stability

- Excellent at high temperature

- Strength

- >40 MPa (Cold Crushing Strength)

- Specific Gravity

- 2.80 3.10 g/cm

- Thermal Conductivity

- Good (varies with composition)

- Color

- Dark grey to black

Alumina Magnesia Carbon Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

About Alumina Magnesia Carbon Bricks

Alumina Magnesia Carbon Bricks contains aluminum and silicon. It can be used in steel ladle bottom and metal zone, baking furnaces and blast furnace hearth. We are a leading Manufacture, Supplier and Exporter of Best Quality Alumina Magnesia Carbon Bricks as per the customer's needs and requirements.

Long Service Life in Steel Making Environments

Alumina Magnesia Carbon Bricks are specifically developed to endure harsh steel making conditions. Their ability to withstand high temperatures, mechanical stress, and corrosive slag results in an extended operational lifespan, reducing downtime and frequent replacements for ladle linings and electric arc furnace components.

Superior Resistance to Thermal and Chemical Stress

These bricks provide excellent thermal shock and spalling resistance, thanks to their optimized chemical composition and low porosity. Enhanced with additives for improved oxidation resistance, they remain structurally stable and retain strength even during rapid temperature fluctuations and exposure to steelmaking slag and molten metals.

Customizable Design and Reliable Performance

Manufactured in both standard and tailored sizes, the bricks offer dimensional stability and smooth surface finish. With high density (3.10 g/cm3) and low water absorption, their physical integrity ensures consistent performance. Exported globally from India, they meet diverse requirements for steel industry applications.

FAQ's of Alumina Magnesia Carbon Bricks:

Q: How do Alumina Magnesia Carbon Bricks enhance thermal shock resistance in steel manufacturing?

A: These bricks are designed with a balanced composition of alumina, magnesia, and carbon, which together provide excellent thermal shock resistance. They withstand rapid temperature changes encountered in ladle linings and furnace walls, reducing the risk of cracking and structural failure.Q: What benefits do additives provide for oxidation resistance in these bricks?

A: Additives integrated during manufacturing enhance the bricks' ability to resist oxidation at high temperatures. This prolongs their service life, maintains structural integrity, and prevents premature degradation from exposure to oxygen in steel making environments.Q: When should I choose customized sizes or shapes of these bricks for my project?

A: Custom sizes or shapes should be selected when your steel manufacturing setup involves unique furnace designs or requires specific linings for irregular areas. Customization improves installation efficiency and optimizes brick performance for specialized applications.Q: Where are Alumina Magnesia Carbon Bricks typically used in the steel industry?

A: They are widely utilized in steel ladle lining, electric arc furnace (EAF) roofs, side walls, and other high-temperature zones that require robust, corrosion-resistant refractory solutions with excellent dimensional stability.Q: What is the process for maintaining these bricks in steel making furnaces?

A: Regular visual inspection, timely cleaning to remove slag buildup, and replacement of bricks meeting wear thresholds will sustain their performance. Proper installation and adherence to maintenance protocols minimize operational disruptions.Q: How does the low apparent porosity of these bricks improve their effectiveness during use?

A: With apparent porosity of 10%, these bricks minimize penetration by slag and molten metals, contributing to high resistance against chemical attack and maintaining strength throughout their service life in aggressive working conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Magnesite Bricks

Price Range 2.00 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : 3.04.5 W/mK at 1000C

Chemical Composition : MgO (Magnesium Oxide): 8595%, SiO2: 36%, Fe2O3: 12%

Product Type : Refractories

Shape : Other, Rectangular, customized

Mullite Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : Low

Chemical Composition : Al2O3, SiO2

Product Type : Refractories

Shape : Other, Rectangular, Brick Shape

Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : High

Chemical Composition : MgO > 70%, C = 1020%

Product Type : Refractories

Shape : Other, Rectangular / Brickshaped

Cupola Bricks

Price Range 0.20 - 0.50 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : Low

Chemical Composition : High Alumina, Silica, Magnesia

Product Type : Refractories

Shape : Other, Rectangular, Arch, Wedge

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry