Fire Bricks

Fire Bricks Specification

- Hardness (%)

- Above 60%

- Purity(%)

- 85-99%

- Density

- 2.0 Gram per cubic centimeter(g/cm3)

- Form

- Solid Block

- Application

- Furnaces, Kilns, Fireplaces, Lining of Boilers, High Temperature Construction

- Chemical Composition

- Al2O3 (Alumina), SiO2 (Silica), minor Fe2O3, CaO, MgO

- Water Absorption

- 15-25%

- Melting Point

- 1700C - 1800C

- Usage & Applications

- Used for construction of fire resistant structures and lining of high temperature equipment.

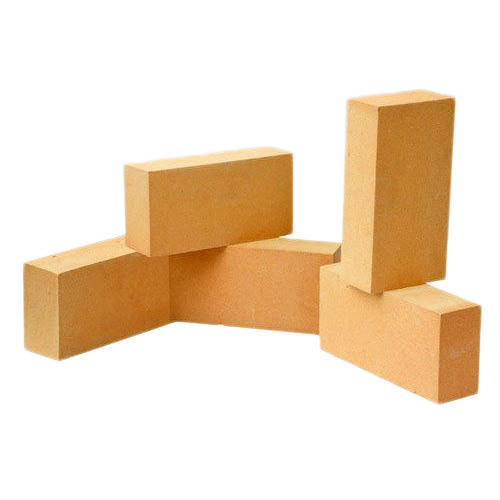

- Surface Finish

- Smooth

- Product Type

- Refractories

- Types of Refractories

- Acidic Refractory

- Shape

- Rectangular Brick

- Porosity

- 22-28%

- Dimensional Stability

- Excellent at High Temperatures

- Strength

- Cold Crushing Strength: 35-45 MPa

- Specific Gravity

- 2.1 - 2.4

- Thermal Conductivity

- 0.8 - 1.3 W/m.K

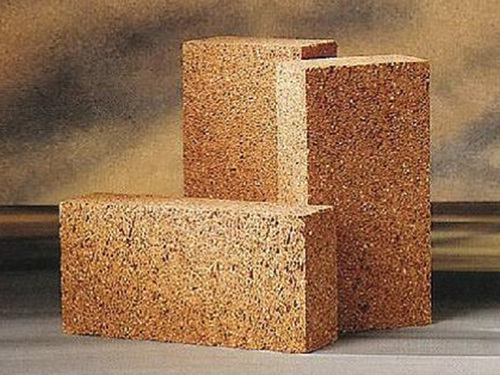

- Color

- Light Yellowish, Off White

Fire Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa

About Fire Bricks

Fire Bricks is a block of ceramic material used in lining furnaces, kilns,fireboxes, and fireplaces. It is built primarily to withstand high temperature,but will also usually have a low thermal conductivity for greater energy efficiency. In the making of firebrick, fireclay is fired in the kiln until it is partly vitrified. We are a leading Manufacture, Supplier and Exporter of Best Quality of Fire brick as per the customers needs and requirements.

Superior Strength and Thermal Stability

These fire bricks provide outstanding cold crushing strength (3545 MPa) and excellent dimensional stability, enabling reliable performance in intense thermal environments. Designed to withstand up to 1400C and featuring high resistance to abrasion, they are perfect for applications requiring prolonged exposure to extreme heat.

Highly Resistant to Chemical and Mechanical Stress

Thanks to their acidic refractory properties and good acid resistance, these bricks endure aggressive environments commonly found in industrial furnaces and kilns. The smooth surface finish, bulk modulus of 2.1 GPa, and hardness above 60% further enhance their durability against mechanical and chemical stress.

Versatile Applications and Easy Handling

Ideal for constructing fire-resistant structures and lining various high-temperature equipment, our fire bricks are tailored for industry, commercial, and residential use. Stacked on pallets and shrink-wrapped, they are easy to transport and handle at construction sites or factories.

FAQs of Fire Bricks:

Q: How are these fire bricks used in high-temperature applications?

A: These fire bricks are commonly used for lining furnaces, kilns, boilers, and fireplaces. Their high thermal stability and cold crushing strength allow them to maintain structure and insulation at service temperatures up to 1400C, making them suitable for constructing fire-resistant barriers in various industrial settings.Q: What is the benefit of using fire bricks with high cold crushing strength and abrasion resistance?

A: High cold crushing strength (350380 kg/cm) ensures the bricks can withstand mechanical and thermal stresses without deforming or cracking. Combined with very high abrasion resistance, these bricks offer durability and longevity even in environments with frequent mechanical impact or material movement.Q: When should I consider using these acidic refractory fire bricks?

A: You should opt for these acidic refractory bricks when building or repairing structures exposed to high heat and acidic conditions, such as industrial furnaces, reactors, and kiln linings. Their good acid resistance and thermal properties protect against chemical corrosion and thermal shock.Q: Where are these fire bricks typically installed?

A: These fire bricks are widely installed in industrial settings, such as linings for furnaces, kilns, and boilers, as well as in fireplaces and high-temperature construction projects. Their versatility makes them suitable for both commercial and residential fire-resistant constructions.Q: What is the process for ensuring quality and proper packaging of the bricks?

A: Each fire brick is manufactured according to IS 6:1983 standards, with additional customizations available on order. Finished bricks are carefully stacked on pallets and shrink-wrapped to protect against damage during transportation and to facilitate easy on-site handling.Q: How does the chemical composition enhance their performance?

A: The bricks are formulated with a high proportion of alumina (Al2O3) and silica (SiO2), ensuring superior heat resistance and dimensional stability. Minor additions of Fe2O3, CaO, and MgO further improve their durability, acid resistance, and mechanical strength for demanding applications.Q: What advantages does the smooth surface finish and dimensional stability provide?

A: A smooth surface finish promotes tight fitting and uniform lining, reducing gaps where heat loss can occur. Excellent dimensional stability at elevated temperatures ensures the bricks retain their shape and integrity, minimizing maintenance and enhancing the lifespan of the structure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Silicon Carbide Brick

Price Range 2.00 - 10.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : High (10 16 W/mK)

Water Absorption : <0.5%

Usage & Applications : Lining of kilns & furnaces, heat exchangers, boilers, power plants

Porosity : 14 18%

Fire Clay Bricks

Price Range - 2.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : 1.0 1.3 W/mK at 1000C

Water Absorption : 15 20%

Usage & Applications : Ideal for construction of lining in furnaces, chimneys, boilers, and other hightemperature industrial applications.

Porosity : 20 28%

Insulation Bricks

Price Range 1.00 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : Low thermal conductivity, 0.250.35 W/mK

Water Absorption : 1820%

Usage & Applications : Thermal insulation, lining for kilns, stoves and furnace walls

Porosity : High porosity (4560%)

Silica Bricks

Price Range 1.50 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Thermal Conductivity : 1.01.2 W/mK

Water Absorption : < 5%

Usage & Applications : Used in thermal processing industries, glass manufacturing, steel plants, coke ovens, and other hightemperature furnaces

Porosity : 1622%

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry