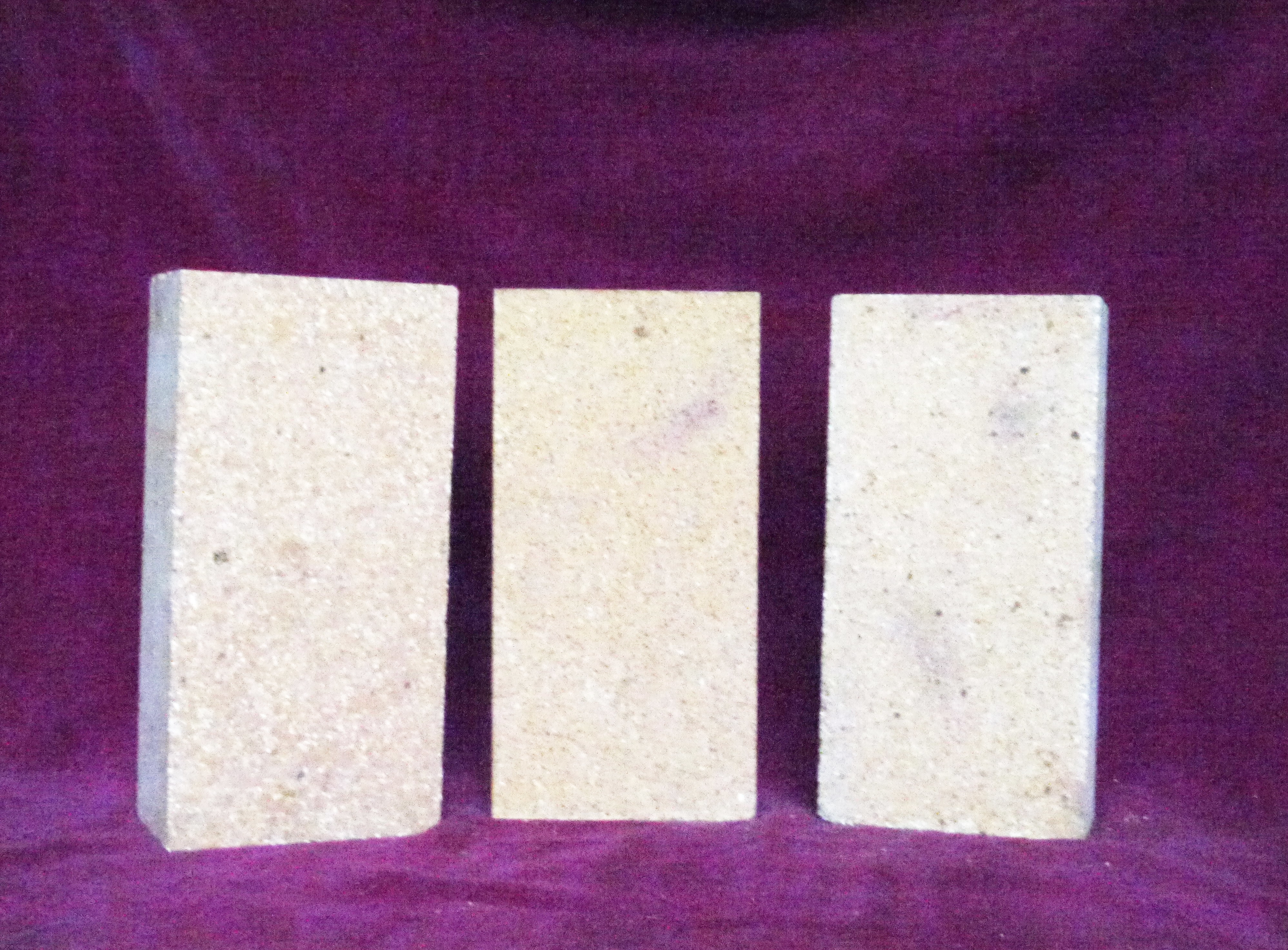

High Alumina Bricks

Price 0.12 USD ($)/ Piece

High Alumina Bricks Specification

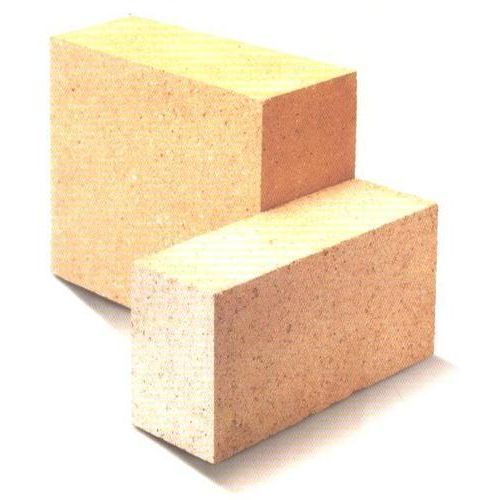

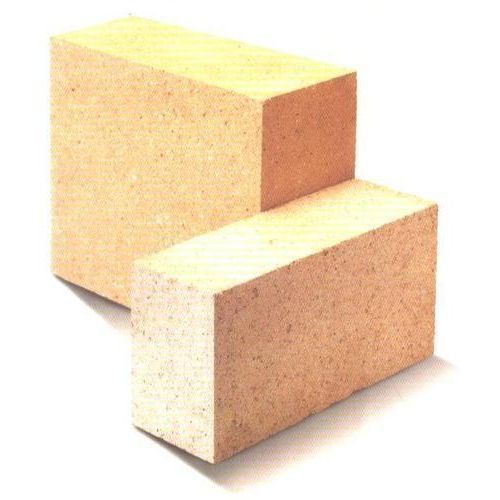

- Form

- Solid Brick

- Melting Point

- 1780C - 1850C

- Application

- Furnaces, kilns, incinerators, and lining in steel and cement industries

- Surface Finish

- Smooth

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Purity(%)

- Alumina content 45% - 80%

- Hardness (%)

- Mohs Hardness: 7 - 8

- Usage & Applications

- Used in steel plants, cement plants, glass industries, foundries, and other high-temperature environments

- Water Absorption

- < 12%

- Chemical Composition

- Al2O3, SiO2, small amounts of Fe2O3, TiO2

- Product Type

- Refractories

- Types of Refractories

- Acidic and Neutral

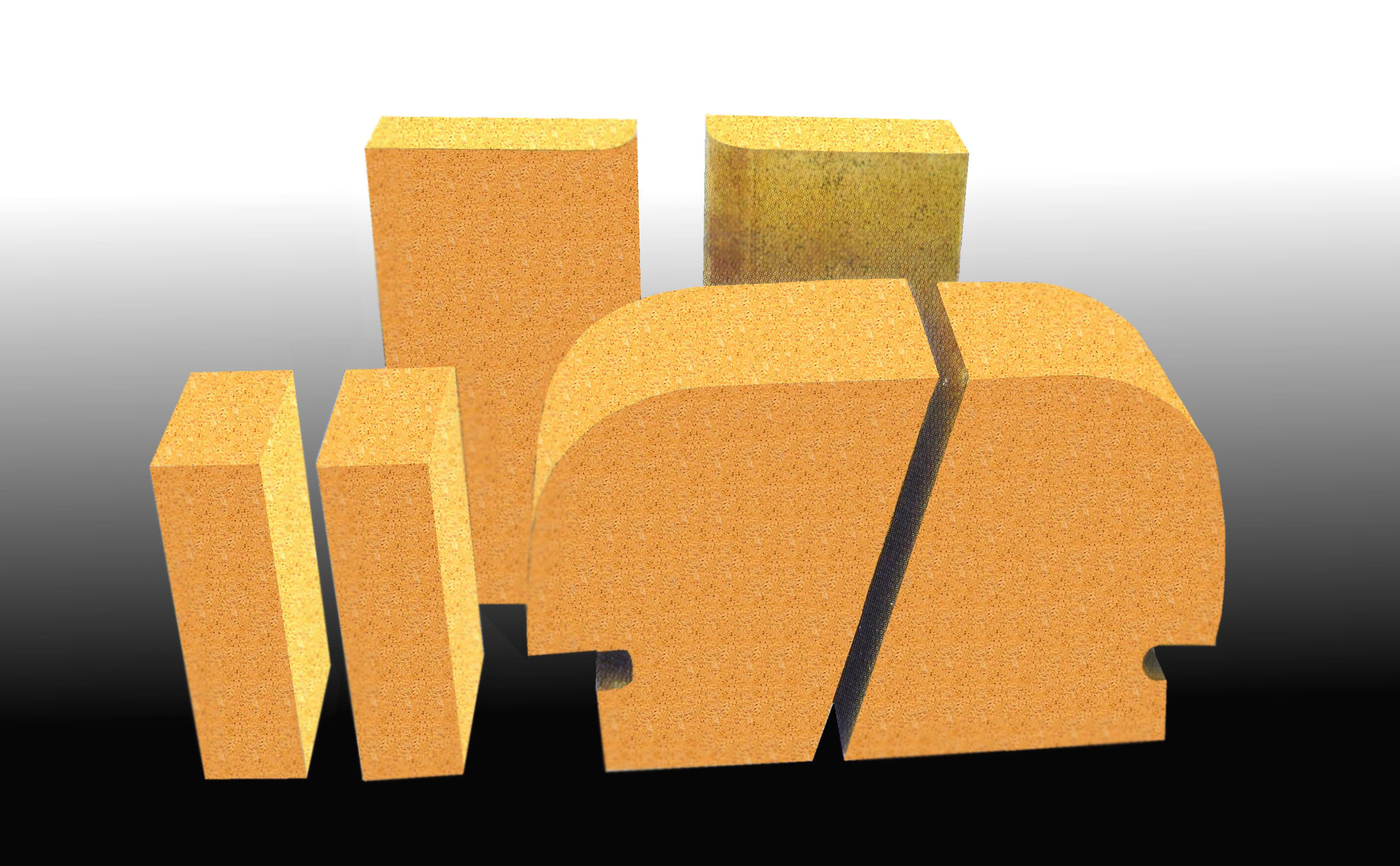

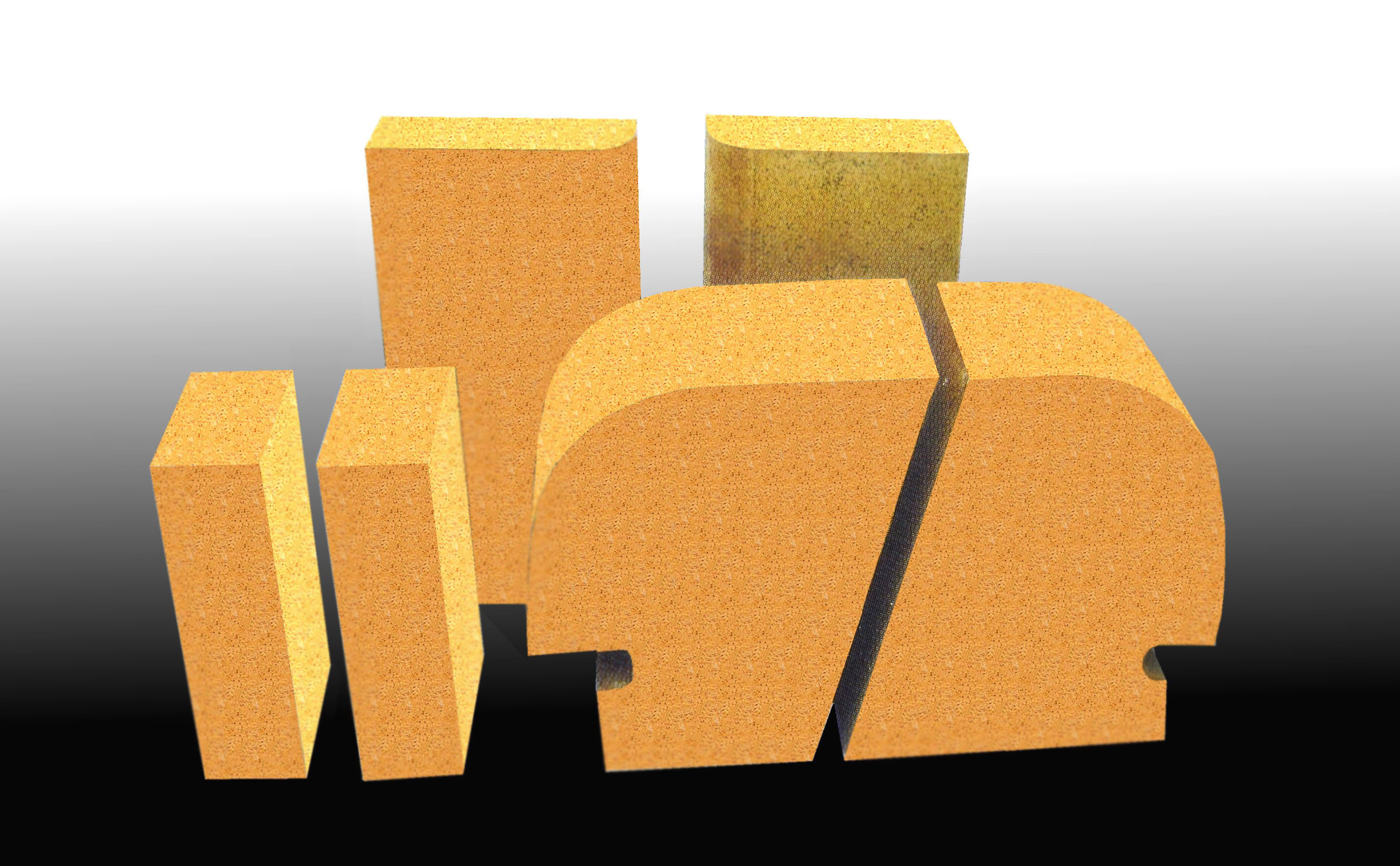

- Shape

- Rectangular, Arch, and Special Shapes

- Porosity

- 18% - 23%

- Dimensional Stability

- Excellent at high temperatures

- Strength

- Cold Crushing Strength > 50 MPa

- Specific Gravity

- 2.3 - 2.65

- Thermal Conductivity

- 0.8 - 1.5 W/mK

- Color

- Light Yellow to Brown

High Alumina Bricks Trade Information

- Minimum Order Quantity

- 2000 Pieces

- FOB Port

- Mundra

- Payment Terms

- Western Union, Letter of Credit (L/C), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 20000 Pieces Per Month

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

About High Alumina Bricks

High Alumina Bricks

Exceptional Thermal and Mechanical Properties

With high refractoriness under load (RUL) exceeding 1450C, and a service temperature up to 1700C, these bricks maintain stability and strength even in extreme conditions. Their superior cold crushing strength (>50 MPa) and high abrasion resistance ensure long-lasting structural integrity in industrial applications.

Versatility in Shape and Application

Offered in standard, arch, and custom shapes, the bricks are suitable for various installations. Their excellent dimensional stability and smooth finish enable use in steel plants, cement kilns, glass furnaces, and incinerators, meeting diverse requirements for lining and insulation.

Reliable Quality and Export Packaging

Certified under ISO 9001:2015, every batch undergoes stringent quality control. Bricks are securely packed on wooden pallets or export-worthy packaging for safe transport, supporting international supply and robust logistics.

FAQ's of High Alumina Bricks:

Q: How are high alumina bricks beneficial for industrial furnaces and kilns?

A: High alumina bricks offer remarkable thermal stability, high abrasion resistance, and superior compressive strength, ensuring reliable performance and longevity in furnaces, kilns, and similar high-temperature installations.Q: What is the standard size available, and are customized dimensions offered?

A: The standard size of our high alumina bricks is 230mm x 114mm x 76mm. We also provide custom sizes and shapes to meet specific installation and application requirements.Q: Where can these bricks be used in the industry?

A: They are widely utilized for lining furnaces, kilns, incinerators, steel and cement plants, glass industries, and foundries-anywhere high-temperature resistance and strength are essential.Q: What process ensures the bricks' high refractoriness and mechanical strength?

A: Our bricks are manufactured using high-purity alumina, advanced firing techniques, and tight quality control. This process guarantees refractoriness above 1450C and compressive strength exceeding 50 MPa.Q: What is the advantage of the brick's thermal expansion and porosity characteristics?

A: With controlled thermal expansion (30~35 107/C) and low apparent porosity (18-23%), these bricks provide exceptional dimensional stability and reduce heat loss, enhancing energy efficiency and safety in high-temperature environments.Q: How are the bricks packaged for export and transportation?

A: Bricks are packed on sturdy wooden pallets using export-worthy materials, ensuring they arrive safely and reliably at international destinations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Alumina Products Category

High Alumina Hanger And Shoulder Bricks

Price 6.00 USD ($) / Piece

Price Range 0.50 - 6.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Specific Gravity : 2.3 2.6

Surface Finish : Smooth

Density : 2.7 Gram per cubic centimeter(g/cm3)

High Alumina Fire Bricks

Price 0.50 USD ($) / Piece

Price Range 0.50 - 3.00 USD ($) / Piece

Minimum Order Quantity : 2000 Pieces

Specific Gravity : 2.3 2.7

Surface Finish : Smooth

Density : 2.7 Gram per cubic centimeter(g/cm3)

High Alumina Cement

Price Range 200.00 - 1000.00 USD ($) / Metric Ton

Minimum Order Quantity : 100 Metric Tons

Specific Gravity : 2.9 3.1

Surface Finish : Fine

Density : 3.1 Gram per cubic centimeter(g/cm3)

High Alumina Castables And Mortar Powder

Price Range 100.00 - 800.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Specific Gravity : 2.6 2.8 g/cm

Surface Finish : Smooth

Density : 2.8 Gram per cubic centimeter(g/cm3)

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry