Mullite Bricks

Mullite Bricks Specification

- Form

- Solid Brick

- Usage & Applications

- Lining of furnaces and kilns, glass tank furnaces, steel industry

- Melting Point

- Approximately 1850C to 1900C

- Water Absorption

- Below 5%

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Hardness (%)

- 72-78%

- Application

- Furnaces, kilns, incinerators, lining in glass and steel industries

- Chemical Composition

- Al2O3, SiO2

- Surface Finish

- Smooth

- Purity(%)

- 85-90%

- Product Type

- Refractories

- Types of Refractories

- Acid Refractory

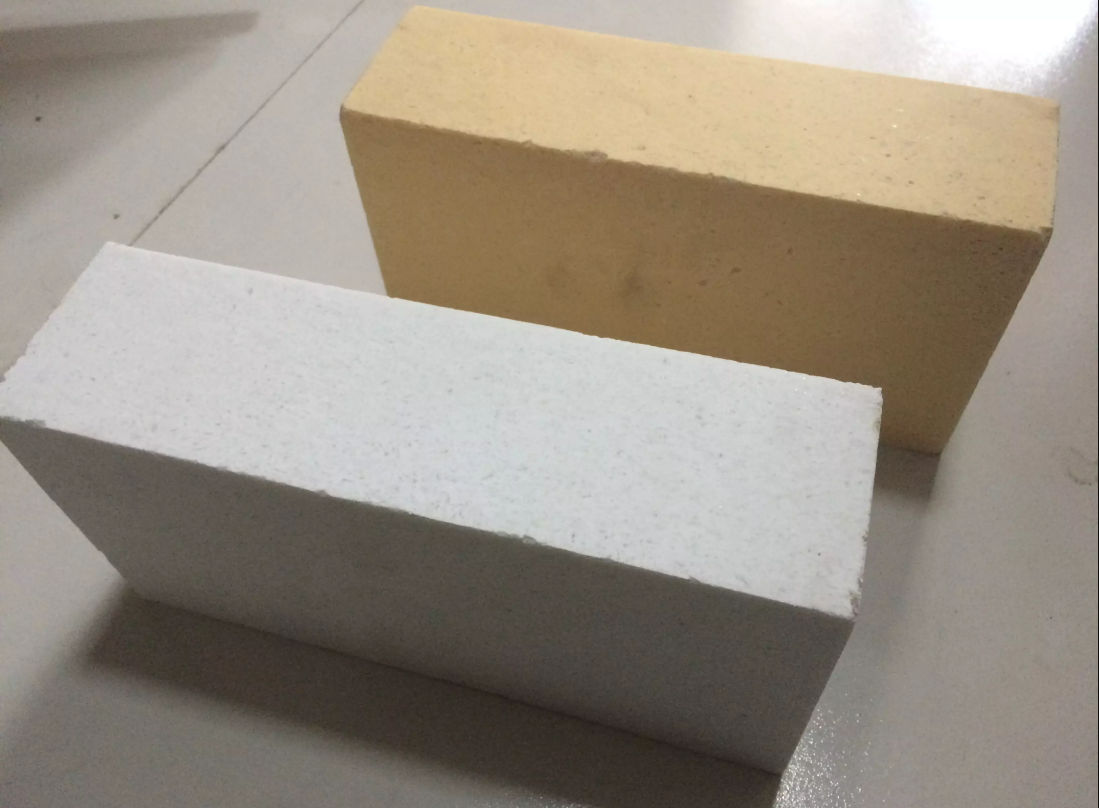

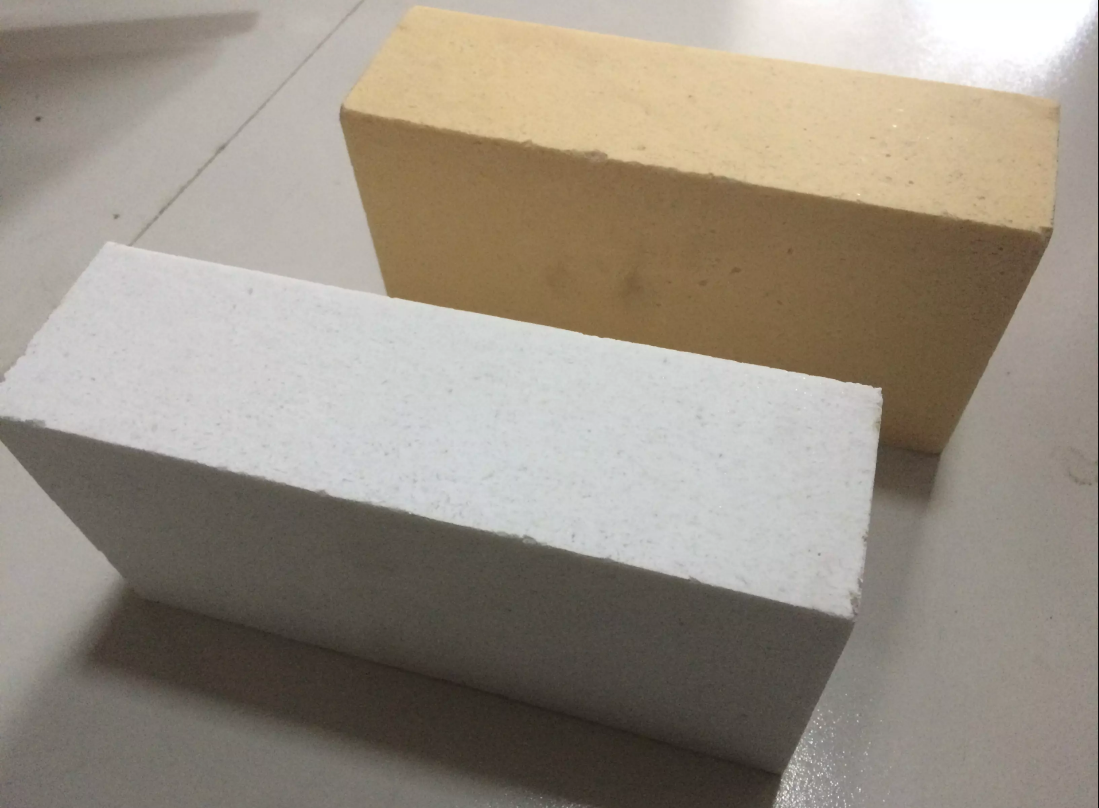

- Shape

- Rectangular, Brick Shape

- Porosity

- 17-23%

- Dimensional Stability

- Excellent at high temperatures

- Strength

- High mechanical strength

- Specific Gravity

- 2.6 - 2.8

- Thermal Conductivity

- Low

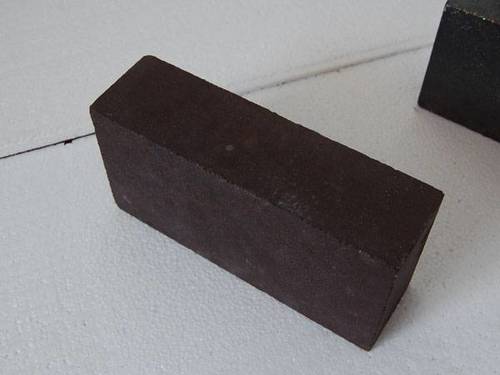

- Color

- Off White, Light Brown

Mullite Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Western Union, Letter of Credit (L/C), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, Western Europe, Central America, Middle East, South America, Asia, Eastern Europe, North America, Africa

About Mullite Bricks

Mullite Bricks

High Temperature Stability

Mullite Bricks offer excellent stability at temperatures up to 1700C, making them suitable for use in furnaces, kilns, and reactors exposed to rapid heating and cooling cycles. Their low thermal conductivity and superior resistance to thermal shock ensure dependable performance in demanding industrial environments.

Customizable Dimensions and Packaging

Regardless of your project's requirements, these refractory bricks are available in the standard 230 114 65 mm size, but customization is possible to fit unique designs. For secure transport and storage, all bricks are carefully packed using wooden pallets with plastic film wrapping, ensuring integrity during shipment.

Premium Composition for Industrial Durability

Constructed primarily from high-purity alumina (over 70%) and silica, with controlled porosity and high mechanical strength, these bricks deliver enduring performance in harsh chemical and thermal conditions. Their smooth surface finish and controlled water absorption contribute to their longevity and reliability.

FAQ's of Mullite Bricks:

Q: How are Mullite Bricks typically used in industrial applications?

A: Mullite Bricks are extensively used to line furnaces, kilns, glass tank furnaces, and incinerators in industries such as steel, glass, and chemical processing, due to their high strength and resistance to extreme heat.Q: What benefits do Mullite Bricks offer over other refractory materials?

A: These bricks provide excellent mechanical strength, low thermal expansion, and exceptional resistance to thermal shock, ensuring long service life and reliable performance at high temperatures up to 1700C.Q: When should Mullite Bricks be chosen for furnace lining?

A: Mullite Bricks are ideal when high service temperatures, excellent thermal shock resistance, and a low rate of thermal expansion are essential for the process, particularly in furnaces and kilns that experience rapid temperature changes.Q: Where can Mullite Bricks be installed?

A: They can be installed in various high-temperature environments, including industrial furnaces, kiln linings, incinerators, and inner linings for glass and steel-manufacturing units, wherever durability and high thermal resistance are required.Q: What is the process for customizing Mullite Brick sizes?

A: Customers can request customization based on their application needs; manufacturers can alter brick dimensions while maintaining the same material properties and structural integrity, ensuring a tailored fit for any installation.Q: How does the packaging ensure Mullite Bricks arrive undamaged?

A: Bricks are packed on sturdy wooden pallets with plastic film wrapping, providing protection against moisture and mechanical damage during transport and storage, which preserves their quality and structural performance.Q: What key properties make Mullite Bricks beneficial in the steel and glass industries?

A: Their high alumina content, low porosity, strong mechanical strength, and excellent dimensional stability under thermal stress make them particularly advantageous in these sectors, ensuring reliable operations and reduced maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Alumina Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : 98%

Strength : >40 MPa (Cold Crushing Strength)

Thermal Conductivity : Good (varies with composition)

Surface Finish : Smooth

Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : Above 97%

Strength : Cold Crushing Strength: 2535 MPa

Thermal Conductivity : High

Surface Finish : Smooth

Magnesite Bricks

Price Range 2.00 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : 85% to 95%

Strength : Cold Crushing Strength (CCS): 3060 MPa

Thermal Conductivity : 3.04.5 W/mK at 1000C

Surface Finish : Smooth

Cupola Bricks

Price Range 0.20 - 0.50 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : >98%

Strength : Cold Crushing Strength >350 kg/cm

Thermal Conductivity : Low

Surface Finish : Smooth

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry