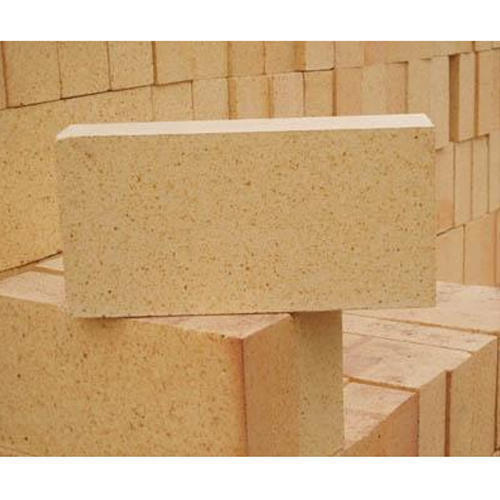

High Alumina Fire Bricks

High Alumina Fire Bricks Specification

- Application

- Furnaces, Kilns, Stoves, Boilers, Incinerators, Chimneys lining, Steel Industry, Cement Industry

- Water Absorption

- < 10%

- Melting Point

- > 1700C

- Hardness (%)

- > 90%

- Surface Finish

- Smooth

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Alumina content: 40-90%

- Purity(%)

- Up to 90%

- Form

- Solid Brick

- Usage & Applications

- Industrial lining for furnaces, kilns, boilers; construction in high-temperature zones

- Product Type

- Refractories

- Types of Refractories

- High Alumina

- Shape

- Rectangular / Custom Shapes

- Porosity

- 19% - 23%

- Dimensional Stability

- High; Maintains Shape at High Temperature

- Strength

- Cold Crushing Strength: 35 - 80 MPa

- Specific Gravity

- 2.3 - 2.7

- Thermal Conductivity

- 1.5 - 2.0 W/mK (at 1000C)

- Color

- Light Yellow / Buff

High Alumina Fire Bricks Trade Information

- Minimum Order Quantity

- 2000 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 20000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa

About High Alumina Fire Bricks

We offer premium quality acid resistant bricks, tiles and special shapes. These are commonly used in power stations, storage vessels, petrochemical industry, galvanizing plants and similar places where high chemical resistance isrequired.

Engineered for Extreme Performance

Designed to meet the rigorous demands of industrial environments, High Alumina Fire Bricks provide exceptional resistance to thermal shock and maintain dimensional stability under high temperature. Their low apparent porosity (18% - 23%) and superior wear resistance make them a reliable choice for prolonged use in furnaces, kilns, and similar applications.

Custom Sizes and Versatile Applications

These bricks are available in both standard 230 x 115 x 75 mm dimensions and customized shapes, allowing precise fit for specialized linings in steel, cement, and other high-temperature industries. They are widely used for lining furnaces, boilers, incinerators, and chimneys, providing structural integrity and thermal insulation.

Adhering to Industry Standards

Manufactured in compliance with IS:6 and IS:8 Indian standards, High Alumina Fire Bricks guarantee consistent quality and performance. Their high alumina content (up to 90%) ensures excellent purity and strength, while the advanced manufacturing process provides a smooth finish and low water absorption, maximizing lifespan and reliability.

FAQ's of High Alumina Fire Bricks:

Q: How are High Alumina Fire Bricks used in industrial applications?

A: High Alumina Fire Bricks are primarily used for lining furnaces, kilns, stoves, incinerators, boilers, and chimneys. Their role is to provide thermal insulation and structural support under extreme heat, ensuring safe and efficient operation in industries like steel, cement, and power generation.Q: What advantages do High Alumina Fire Bricks offer compared to other refractory bricks?

A: These bricks deliver superior resistance to high temperatures (up to 1790C), excellent thermal shock resistance, high compressive strength (35 - 80 MPa), and low porosity, which translates to better insulation and durability. Their high alumina content ensures exceptional chemical stability and wear resistance, reducing maintenance frequency.Q: When should High Alumina Fire Bricks be selected over standard fire bricks?

A: You should opt for High Alumina Fire Bricks when the application involves sustained exposure to very high temperatures, aggressive chemical environments, or frequent thermal cycling. Situations requiring enhanced mechanical strength and longevity-such as steel or cement kilns-particularly benefit from these grades.Q: What is the process for installing High Alumina Fire Bricks in industrial linings?

A: Installation typically involves preparing the furnace or kiln shell, placing bricks in a staggered (bonded) format to reduce heat loss and increase strength, and securing them using refractory mortars. Custom shapes and sizes can be produced for seamless lining and minimal gaps, ensuring optimal performance.Q: Where are these bricks manufactured and are custom sizes available?

A: High Alumina Fire Bricks are manufactured in India by leading exporters and suppliers. Standard sizes (230 x 115 x 75 mm) are readily available, and manufacturers can provide custom sizes and shapes to fit unique industrial requirements.Q: How does thermal expansion affect the performance of these bricks?

A: With a controlled thermal expansion (0.8% - 1.3% at 1000C), these bricks maintain their shape and stability, even after repeated heating and cooling cycles. This property enhances dimensional stability, reducing the risk of cracking or spalling under severe temperature changes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Alumina Products Category

High Alumina Hanger And Shoulder Bricks

Price Range 0.50 - 6.00 USD ($) / Piece

Price 6.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Density : 2.7 Gram per cubic centimeter(g/cm3)

Surface Finish : Smooth

Chemical Composition : Al2O3 content > 60%, SiO2, Fe2O3

High Alumina Bricks

Price 0.12 USD ($) / Piece

Minimum Order Quantity : 2000 Pieces

Density : 2.7 Gram per cubic centimeter(g/cm3)

Surface Finish : Smooth

Chemical Composition : Al2O3, SiO2, small amounts of Fe2O3, TiO2

Refractory Mortar Powder

Price Range 100.00 - 700.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Density : 2.2 Gram per cubic centimeter(g/cm3)

Surface Finish : Smooth

Chemical Composition : Alumina, Silica, Calcium Oxide (CaO), Minor Oxides

High Alumina Castables And Mortar Powder

Price Range 100.00 - 800.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Density : 2.8 Gram per cubic centimeter(g/cm3)

Surface Finish : Smooth

Chemical Composition : Al2O3 5090%, SiO2, Fe2O3, CaO (varied)

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry