Most Popular Products

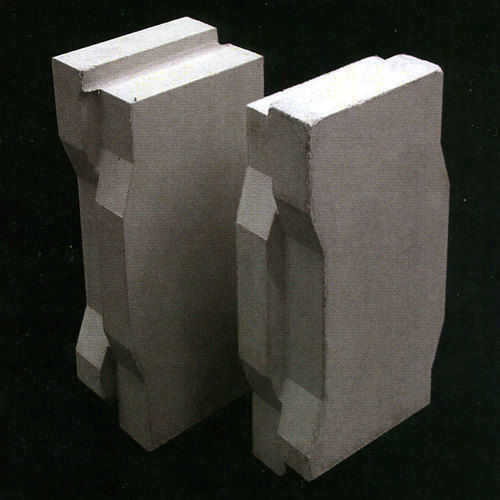

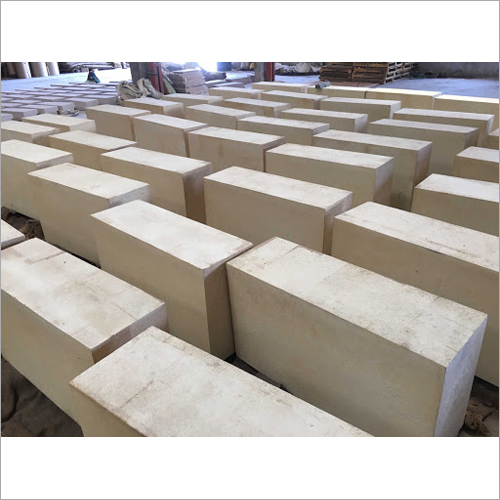

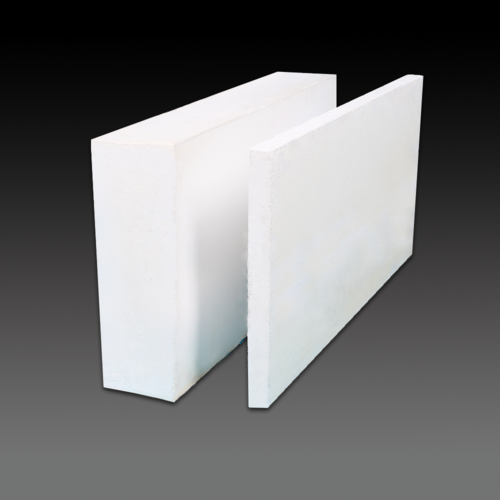

Calcium Silicate Blocks

MOQ : 200 Pieces

Calcium Silicate Blocks Specification

- Application

- Thermal insulation in industrial furnaces, kilns, and high-temperature processes

- Melting Point

- >1000C

- Chemical Composition

- Calcium Silicate, inert fillers, and additives

- Density

- 260 Gram per cubic centimeter(g/cm3)

- Purity(%)

- >90% (Calcium Silicate content)

- Surface Finish

- Smooth or slightly textured

- Form

- Solid Block

- Water Absorption

- <40%

- Usage & Applications

- Thermal insulation, refractory lining, fireproof partitions

- Hardness (%)

- High, retains rigidity at high temperatures

- Product Type

- Refractories

- Types of Refractories

- Insulating Refractory

- Shape

- Rectangular Block

- Porosity

- High, typically 75-80%

- Dimensional Stability

- Excellent at high temperatures, minimal shrinkage

- Strength

- Compressive Strength: 10-15 MPa

- Specific Gravity

- ~1.2 to 1.5

- Thermal Conductivity

- 0.035 0.095 W/mK at 20C

- Color

- White to Off-white

- Acid Resistance

- Moderate

- Length

- Up to 1000 mm

- Fire Resistance

- Excellent, suitable for fire protection

- Thickness

- 25 mm to 100 mm

- Width

- Up to 600 mm

- Toxicity

- Non-toxic and asbestos free

- Maximum Service Temperature

- Up to 1100°C

- Sound Absorption

- Good sound insulation properties

- Alkalinity

- Alkaline

- Odor

- Odorless

- Thermal Stability

- Retains properties at operating temperature range

Calcium Silicate Blocks Trade Information

- Minimum Order Quantity

- 200 Pieces

- FOB Port

- Mundra

- Payment Terms

- Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 2000 Pieces Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

About Calcium Silicate Blocks

Calcium Silicate Blocks

We are offering premium quality Plain Calcium Silicate Blocks which is known as one of the effective insulating elements that can be used to insulate high temperature pipes and various other equipment. It is widely used due to its capability to withstand high compressive strength and a temperature in between 650 to 930 degree Celsius to maintain the structural integrity. This slab like insulation unit also offers excellent resistance against the moisture and corrosion to increase the service life.

Exceptional Thermal Insulation Performance

Calcium Silicate Blocks are engineered to deliver superior thermal insulation properties in high-temperature environments. They maintain structural integrity and retain essential performance even when exposed to temperatures up to 1100C. Their low thermal conductivity ensures efficient heat containment, making them suitable for applications in industrial furnaces, kilns, and specialized fireproofing tasks.

Safe and Durable Material for Industrial Applications

With a non-toxic, asbestos-free formulation, Calcium Silicate Blocks provide dependable fire protection and sound insulation. Their high alkaline content, excellent compressive strength, and minimal shrinkage at elevated temperatures make them durable and long-lasting solutions for refractory linings and partition walls. The blocks' good sound absorption adds further protection in noisy, high-stress settings.

FAQ's of Calcium Silicate Blocks:

Q: How are Calcium Silicate Blocks installed for thermal insulation purposes?

A: Calcium Silicate Blocks can be cut to size and fixed to surfaces using mechanical anchoring or high-temperature adhesives. Installation should be carried out by trained professionals to ensure optimal thermal and fire resistance performance in industrial furnaces, kilns, or partitions.Q: What benefits do Calcium Silicate Blocks offer compared to traditional insulating materials?

A: These blocks provide superior fire resistance up to 1100C, excellent dimensional stability at high temperatures, high compressive strength, and are non-toxic and asbestos-free. Their low thermal conductivity improves energy efficiency and reduces heat loss, while their sound insulation properties enhance workplace safety.Q: When is it recommended to use Calcium Silicate Blocks in industrial settings?

A: Calcium Silicate Blocks are ideal when reliable thermal insulation, fireproofing, and sound insulation are required in environments such as furnaces, kilns, or other high-temperature processes. They ensure operational safety and longevity under extreme thermal conditions.Q: Where are Calcium Silicate Blocks commonly applied in industry?

A: These blocks are commonly used as insulation materials in refractory linings, industrial furnaces, kiln walls, fireproof partitions, and protective barriers for high-temperature equipment. They are supplied across various industries, including manufacturing and energy production.Q: What is the process of manufacturing Calcium Silicate Blocks?

A: Calcium Silicate Blocks are manufactured by blending calcium silicate with inert fillers and additives, shaping the mixture into rectangular blocks, and curing them to achieve the desired density, porosity, and rigidity. Strict quality control ensures consistent properties like high purity and compressive strength.Q: How does the alkaline nature of Calcium Silicate Blocks affect their applications?

A: The alkaline property of these blocks contributes to their overall stability under thermal stress and enhances their resistance to chemical corrosion, especially in environments exposed to moderate acid attack, ensuring durability in various industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Tiles & Blocks Category

Refractory Tiles

Price 0.15 USD ($) / Piece

Minimum Order Quantity : 3000 Pieces

Purity(%) : >90%

Form : Solid

Shape : Other, Rectangular, Square and customized

PCPF Blocks

Price Range 40.00 - 95.00 USD ($) / Piece

Minimum Order Quantity : 200 Pieces

Purity(%) : 85%98%

Form : Solid Block

Shape : Other, Rectangular/Custom

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry