Acidic Ramming Mass

Acidic Ramming Mass Specification

- Purity(%)

- > 99% (Silica)

- Form

- Loose Granular/Powder

- Hardness (%)

- High, ~7 (Mohs scale)

- Application

- Lining of induction furnaces for melting metals, especially steel and iron

- Water Absorption

- Negligible

- Usage & Applications

- Induction furnace lining, patching, repairing and sintering

- Surface Finish

- Uniform and granular

- Chemical Composition

- Silica (SiO) > 99%, Trace impurities (Al2O3, Fe2O3, CaO, MgO)

- Melting Point

- 1770C - 1830C

- Density

- 1.8 Gram per cubic centimeter(g/cm3)

- Product Type

- Refractories

- Types of Refractories

- Acidic Refractories

- Shape

- Granular / Powder

- Porosity

- Low, ensuring higher density and strength

- Dimensional Stability

- Excellent stability at high temperatures

- Strength

- High mechanical strength, especially after sintering

- Specific Gravity

- 2.6 - 2.7

- Thermal Conductivity

- Low, suitable for thermal insulation

- Color

- White to Off-white

- Moisture Content

- < 0.5%

- Bulk Density

- 1.75 - 1.85 g/cm³

- Shelf Life

- 12 months when stored properly

- Loss on Ignition

- < 0.5%

- Packaging Type

- HDPE Bags / Jumbo bags (25 kg, 50 kg, 1 ton)

- Sintering Temperature

- Approx. 1200°C - 1350°C

- pH

- Neutral to slightly acidic

- Grain Size

- 0-5 mm (customizable as per furnace design)

Acidic Ramming Mass Trade Information

- Minimum Order Quantity

- 20 MT Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 500 Metric Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

About Acidic Ramming Mass

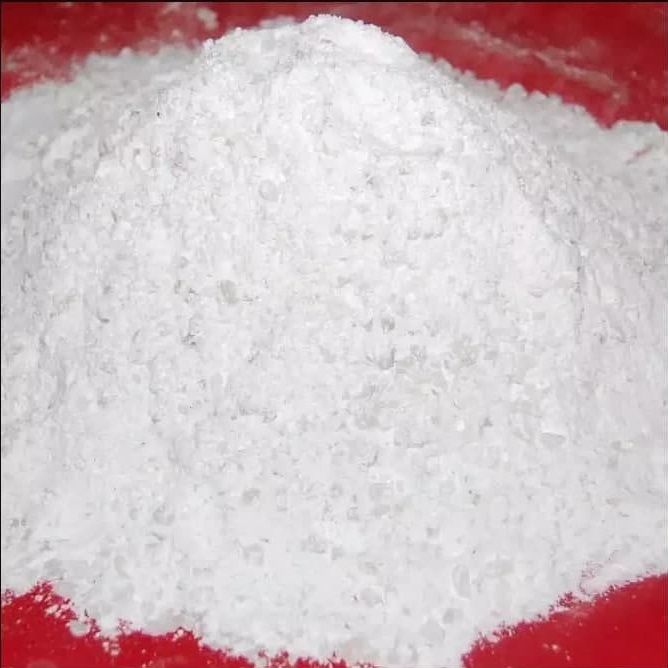

Acidic Ramming Mass

AcidicRamming Mass also known as silica ramming mass. It is used in CorelessInduction Furnaces, for melting of scrap. High performance Silica Ramming Mixesdesigned to minimize erosion in induction melting. Silica ramming mass cansafely be used up to an operating temperature of 1700C. We are a leadingManufacture, Supplier and Exporter of Best Quality of Acidic Ramming Mass asper the customers needs and requirements.

Therole of Acidic Ramming Mass in steel melting through induction Furnace is veryimportant. Its important features are removing iron or steel contents by thepowerful magnet, eliminate the moisture and store the ramming mass in dry anddust free area. Acidic ramming mass offered by CMS INDUSTRIES is known for itschemical and physical properties in the foreign markets.

Superior Performance for Induction Furnace Linings

Acidic Ramming Mass is formulated for exceptional lining performance in induction furnaces, ensuring stability and durability at high operational temperatures. Its high silica content delivers reliable resistance to melt corrosion and supports thermal insulation, protecting the furnace structure while optimizing energy efficiency. Users benefit from reduced downtime and enhanced furnace lifespan.

Customizable Grain Size and Reliable Packaging

Available in granular or powder form with a wide range of adjustable grain sizes (0-5 mm), Acidic Ramming Mass can be tailored to your specific furnace design requirements. Packaging options, including 25 kg, 50 kg, and 1-ton HDPE or jumbo bags, safeguard product integrity during storage and handling, extending shelf life and facilitating ease of use for manufacturers, exporters, and suppliers.

FAQ's of Acidic Ramming Mass:

Q: How is Acidic Ramming Mass applied in induction furnace linings?

A: Acidic Ramming Mass is spread and compacted manually or pneumatically onto furnace walls and the bottom, then sintered at approximately 1200C - 1350C to form a hard, durable protection layer for melting steel and iron.Q: What are the main benefits of using this product for furnace lining?

A: The material provides excellent thermal insulation, high mechanical strength after sintering, and remarkable dimensional stability even at elevated temperatures, leading to longer furnace life and reduced risk of contamination.Q: When should the ramming mass be replaced or patched?

A: Replacement or patching is recommended when visible wear, erosion, or cracks begin to compromise the integrity of the furnace lining, typically after several melting cycles or as dictated by your operational protocols.Q: Where can Acidic Ramming Mass be sourced in India?

A: This product is widely available through established manufacturers, suppliers, and exporters across India, specializing in refractory materials for the steel and metallurgical industries.Q: What is the recommended storage process for maintaining shelf life?

A: Store Acidic Ramming Mass in its original HDPE or jumbo bags in a cool, dry area, protected from moisture and contaminants, to preserve its quality and performance for up to 12 months.Q: What makes this ramming mass suitable for high-temperature applications?

A: With a melting point up to 1830C and a composition of >99% silica, the ramming mass offers excellent dimensional stability, low porosity, and high strength under extreme heat, making it ideal for induction furnace linings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Minerals Category

Calcined Bauxite

Price Range 100.00 - 500.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Product Type : Refractories

Application : Abrasives, Refractories, Sand Blasting, Road Surfacing, Steel Plants, Furnace Linings

Shape : Other, Grains, Powder, Lumps

Color : Brown, Grey

Feldspar Crystal

Price Range 35.00 - 150.00 USD ($) / Metric Ton

Minimum Order Quantity : 27 Metric Tons

Product Type : Minerals

Application : ceramic , tiles ,glass

Shape : Other

Color : Brown, grey,pink and white

Raw Kaolin Clay

Minimum Order Quantity : 25 Metric Tons

Product Type : Minerals

Application : "Ceramic body, Vitrified Tiles, Glaze Tile, Sanitary ware, Refractory, White Cement, Gray Cement "

Washed China Clay

Price Range 45.00 - 250.00 USD ($) / Metric Ton

Minimum Order Quantity : 25 Metric Tons

Product Type : Minerals

Application : paints, plastics, glass, ,Adhesives Sealants, Cosmetics Soap , rubber ,white cement, Refractory bricks

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry