Foundry Bentonite

Foundry Bentonite Specification

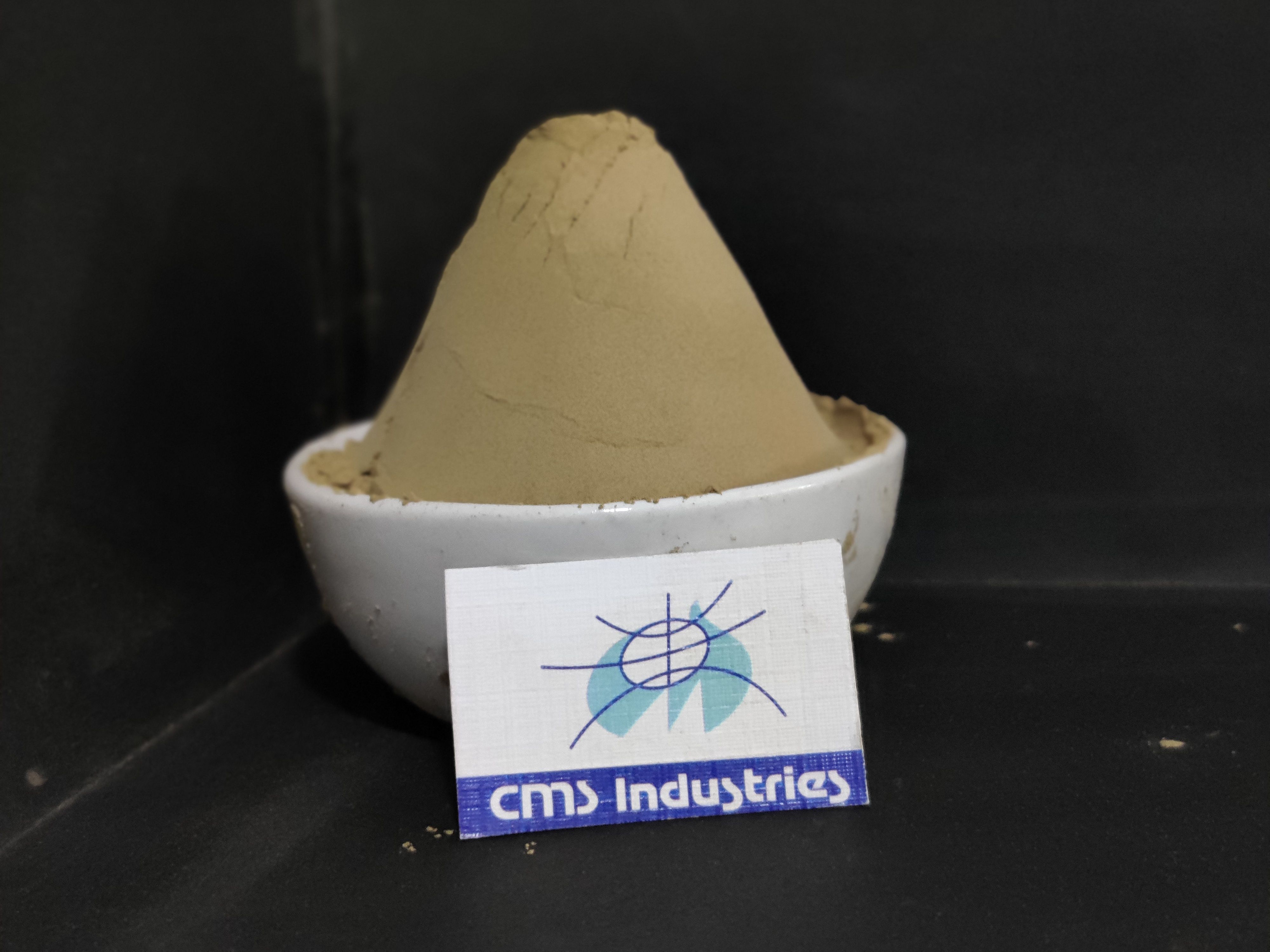

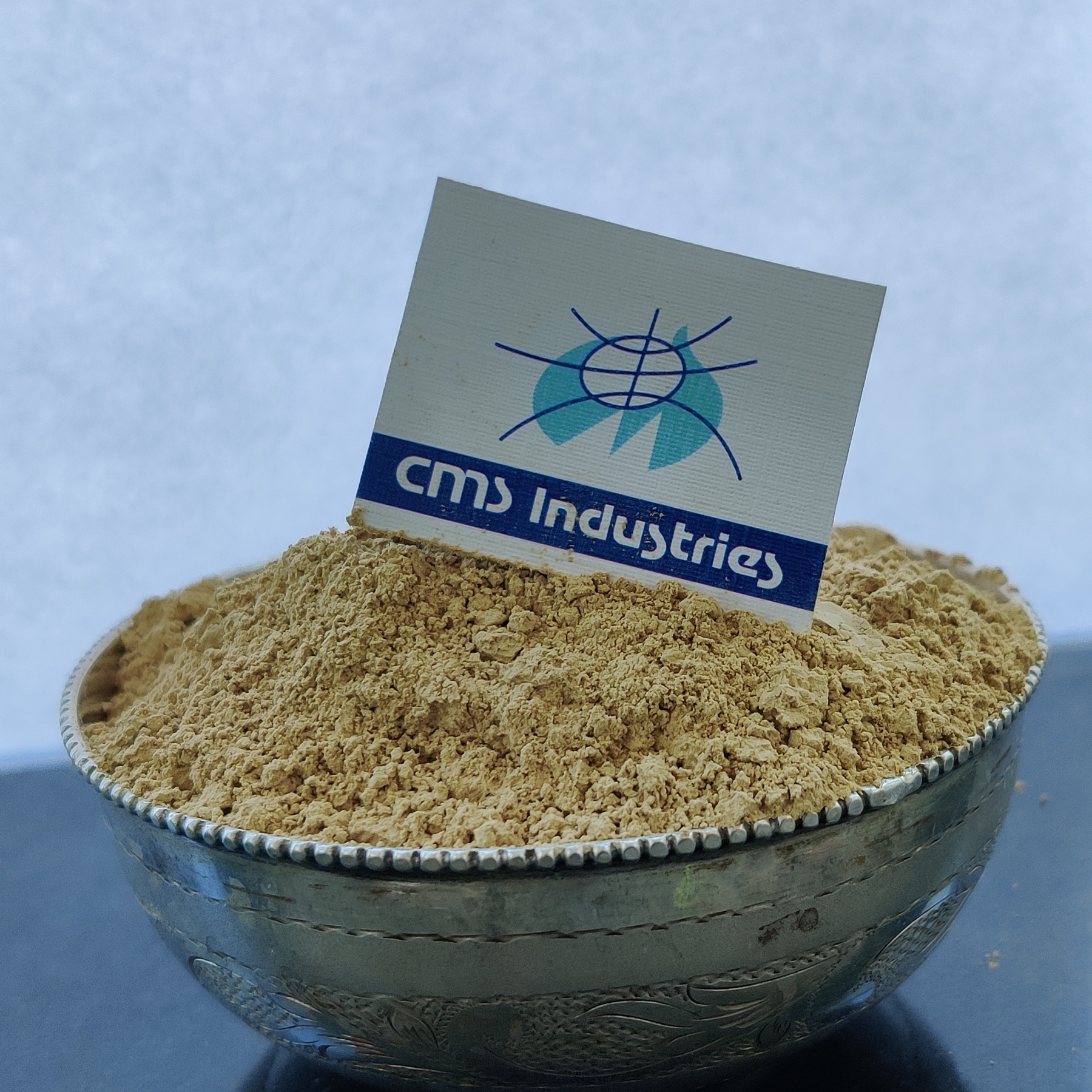

- Appearance

- Powder

- Application

- Chemical Industry

- Color

- Light Yellow

- Density

- 0.9-1.2 g/cm³

- Product Type

- Bentonite

- Swelling Property

- Excellent

- Strength

- High binding

- Mesh Size

- 200 mesh

- Moisture

- 9-13%

- PH Value

- 8-10

Foundry Bentonite Trade Information

- Minimum Order Quantity

- 28 Metric Ton

- Payment Terms

- Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Delivery Time

- 5 Days

- Packaging Details

- Customized and durable packaging, 25kgs & 40 kgs paper bags with liner, PP bags with liner 25 kgs & 50 kgs With and Without pallets, Jumbo bags in 1000 kgs, 1250 kgs, 1350 kgs, 1375kgs & 1400 kgs.

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Certifications

- SGS , QSS , INTERTEK ,API CERTIFICATION , ISO 9001:2015 , BUREAU VERITAS

About Foundry Bentonite

Indione of the largest bentonitemines owner, processor and exporter. We are exporting super premium qualityBentonite at competitive prices with prompt shipments. We provide all types ofpacking with customized printing options. Sodium bentonite is used extensivelyin iron and steel foundries. For large castings which require dry moulds,Sodium bentonite is put to use. Kutch Bentonite is famous for high qualitysodium Bentonite. It is used popularly as a bonding material in the preparationof moulding sand. Our provided all bentonite is mined in the Kachchh Gujarat,India.

WHY CMS INDUSTRIES?

CMS INDUSTRIEs foundry gradebentonite has the ability to develop favourable green and dry compressivestrength and can maintain high thermal stability with the capability todemonstrate excellent ramability. It can sustain mould strength in highpressure moulding. While acting as abinding agent for anhydrous casting sands It has wide moisture tolerance andhigh swelling volume while possessing high wet tensile strength. It also hashigh cohesive strength, thermal stability and low rejects.

Superior Binding and Swelling Performance

Foundry Bentonite is recognized for its potent binding abilities, making it essential in molding and casting applications within the chemical industry. The excellent swelling property supports uniform mixture formation, offering stability and reliability during processing.

Quality Assured by Indian Manufacturers

Sourced and processed by experienced manufacturers, suppliers, and exporters in India, this bentonite powder guarantees high standards of quality and purity. Its controlled moisture and mesh specifications provide consistent results across various industrial usage scenarios.

FAQ's of Foundry Bentonite:

Q: How is Foundry Bentonite utilized in the chemical industry?

A: Foundry Bentonite serves as a binding and absorbing agent in chemical industry applications such as foundry sand preparation, catalyst carriers, and decolorization processes due to its high binding capacity and excellent swelling properties.Q: What benefits does the high binding strength of Foundry Bentonite offer?

A: The elevated binding strength facilitates the formation of strong, cohesive molds, which enhances casting accuracy and reduces defects in finished products. This property makes it ideal for supporting precise chemical processing.Q: When should Foundry Bentonite be used during industrial processing?

A: Foundry Bentonite is typically introduced during the initial stages of mold preparation and formulation in chemical manufacturing, ensuring optimum binding and consistency throughout the process.Q: Where can I source Foundry Bentonite with these specifications?

A: You can obtain this bentonite from reputable exporters, manufacturers, and suppliers based in India, who offer reliable supply chains and quality certifications for industrial applications.Q: What is the process of ensuring moisture content in Foundry Bentonite?

A: Manufacturers monitor and regulate the moisture content between 9-13% during production to maintain optimal physical and chemical properties, resulting in superior performance for end-users.Q: How does the fine mesh size contribute to its industrial effectiveness?

A: The 200 mesh size ensures fine particle distribution, promoting uniform mixing and enhanced absorption, which is critical for chemical processes requiring precise material consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bentonite Category

Bentonite Powder

Price Range 40.00 - 75.00 USD ($) / Metric Ton

Minimum Order Quantity : 28

Application : Chemical Industry

Color : White

Product Type : Bentonite Products

Appearance : Powder

All Grades Of Bentonite

Price Range 40.00 - 75.00 USD ($) / Metric Ton

Minimum Order Quantity : 28

Application : Chemical Industry

Color : Light Yellow

Product Type : Bentonite Products

Appearance : Powder

Oil Drilling Bentonite

Price Range 40.00 - 75.00 USD ($) / Metric Ton

Minimum Order Quantity : 28

Application : Chemical Industry

Color : Light Yellow

Product Type : Bentonite Products

Appearance : Powder

Bentonite Lumps

Price Range 40.00 - 75.00 USD ($) / Metric Ton

Minimum Order Quantity : 28

Application : Chemical Industry

Color : White

Product Type : Bentonite Products

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry