Most Popular Products

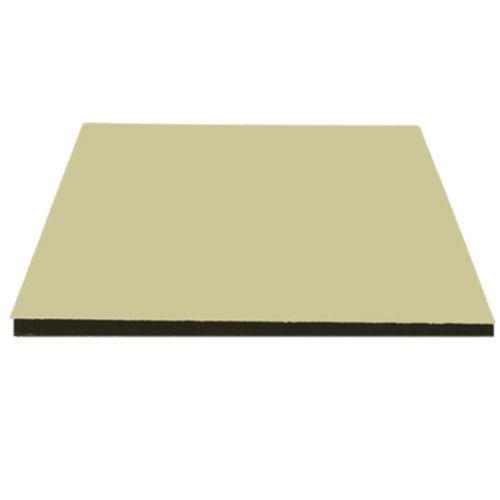

Acid Resistant Tiles

MOQ : 3000 Square Meters

Acid Resistant Tiles Specification

- Surface Finish

- Glazed / Smooth

- Melting Point

- Up to 1700C (varies by chemical composition and thickness)

- Purity(%)

- Above 98%

- Usage & Applications

- Chemical, pharmaceutical, food, and beverage industries; floors, drains, walls, reactor vessels

- Density

- 2.4 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Silica, Feldspar, Kaolin, Quartz, Alumina

- Application

- Acid storage tanks, chemical processing plants, flooring in laboratories and industries, pickling tanks, battery rooms

- Hardness (%)

- Mohs Hardness 7 9

- Water Absorption

- < 0.5%

- Form

- Tile

- Product Type

- Refractories

- Types of Refractories

- Acid Resistant Refractories

- Shape

- Rectangular, Square

- Porosity

- Low

- Dimensional Stability

- Excellent dimensional stability at high temperature and under acid attack

- Strength

- High compressive strength, typically above 700 kg/cm

- Specific Gravity

- 2.35 2.40

- Thermal Conductivity

- Low

- Color

- Light Grey

- Abrasion Resistance

- High

- Acid Resistance

- Excellent, resistant to almost all acids except hydrofluoric acid

- ISO Certification

- ISO 9001:2015

- Standard Compliances

- IS 4457:2007, ASTM C-279

- Installation Method

- Can be fixed using acid-proof cements and mortars

- Size Available

- 200x100x10 mm, 200x100x15 mm, custom sizes

- Bending Strength

- Minimum 40 N/mm²

- Service Temperature

- Up to 1000°C

Acid Resistant Tiles Trade Information

- Minimum Order Quantity

- 3000 Square Meters

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Western Union, Delivery Point (DP), Telegraphic Transfer (T/T), Days after Acceptance (DA)

- Supply Ability

- 30000 Square Meters Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia, Australia

About Acid Resistant Tiles

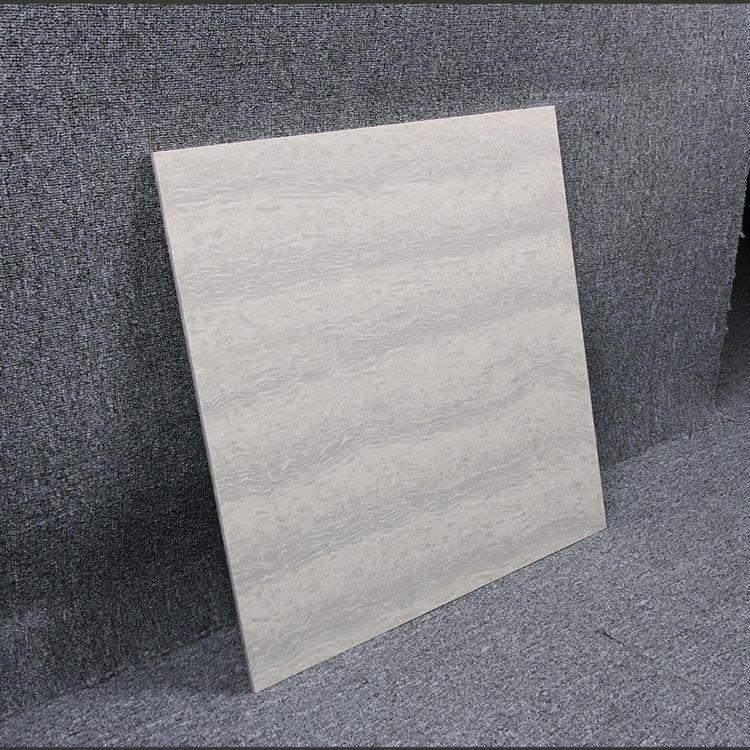

Acid Resistant Tiles

We offer premium quality acid resistant bricks, tiles and special shapes. These are commonly used in power stations, storage vessels, petrochemical industry,galvanizing plants and similar places where high chemical resistance isrequired.

Weare a leading Manufacture, Supplier and Exporter of Best Quality Acid Resistant Titles as per client's needs and requirements. Its main characteristic is water absorption, resistance to acid, compressive strength and flexural strength. Acid Resistant Titles offered by CMS INDUSTRIES is known for its chemical and physical properties in the foreign markets.

Engineered for Extreme Chemical Resistance

Crafted using high-purity raw materials, these tiles deliver exceptional resistance against an extensive range of acids-excluding hydrofluoric acid-ensuring lasting performance in demanding chemical and pharmaceutical settings. Their robust design also makes them highly suitable for the food and beverage industry where hygiene and durability are paramount.

Exceptional Strength and Thermal Stability

With a compressive strength typically above 700 kg/cm2 and minimum bending strength of 40 N/mm2, these acid resistant tiles promise unwavering structural integrity. Their ability to maintain dimensional stability at extreme temperatures (service up to 1000C, melting point up to 1700C depending on composition) ensures a longer lifespan and reduced maintenance in high-temperature applications.

Versatile Applications and Easy Installation

Acid resistant tiles can be installed efficiently with acid-proof cements and mortars, making them versatile for varied industrial applications-from floors, drains, and reactor vessels to battery rooms and pickling tanks. Their low porosity and smooth glazed surface contribute to easy cleaning and minimal maintenance, enhancing their usability in hygiene-sensitive areas.

FAQ's of Acid Resistant Tiles:

Q: How are acid resistant tiles installed in industrial environments?

A: These tiles are installed using acid-proof cements and mortars, ensuring a secure and chemically-resistant bond to floors, walls, drains, and tanks. Proper surface preparation and adherence to recommended installation guidelines are essential for optimal performance.Q: What applications are ideal for using acid resistant tiles?

A: Acid resistant tiles are best suited for settings where surfaces are frequently exposed to aggressive chemicals, such as acid storage tanks, chemical and pharmaceutical plants, pickling tanks, battery rooms, laboratory floors, reactor vessels, and food and beverage industries.Q: What benefits do these tiles provide over conventional flooring materials?

A: Compared to standard tiles, acid resistant tiles offer superior resistance to acids and abrasion, high mechanical strength, low water absorption, and excellent dimensional stability at extreme temperatures. These properties result in extended service life and fewer repairs.Q: When should acid resistant tiles be preferred over other refractory materials?

A: They should be chosen when exceptional chemical and thermal resistance is needed, especially in processes involving strong acids (except hydrofluoric acid) or high operational temperatures. Their performance is ideal for industries where both safety and durability are critical.Q: Where are acid resistant tiles manufactured and supplied from?

A: These tiles are produced and exported by certified manufacturers in India, adhering to ISO 9001:2015 and international standards like IS 4457:2007 and ASTM C-279, ensuring global quality compliance for industrial projects worldwide.Q: What is the chemical composition of these acid resistant tiles?

A: The tiles are primarily composed of high-quality silica, feldspar, kaolin, quartz, and alumina, resulting in high purity (above 98%) and imparting exceptional acid and thermal resistance.Q: How does the surface finish of the tile affect its usage?

A: The glazed or smooth surface finish minimizes porosity and water absorption, facilitating easy cleaning and maintenance. This enhances hygiene and prevents chemical penetration, making the tiles suitable for environments requiring strict sanitary controls.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Acid Resistant Products Category

Acid Resistant Mortar Powder

Price Range 100.00 - 400.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Product Type : Refractories

Shape : Powder

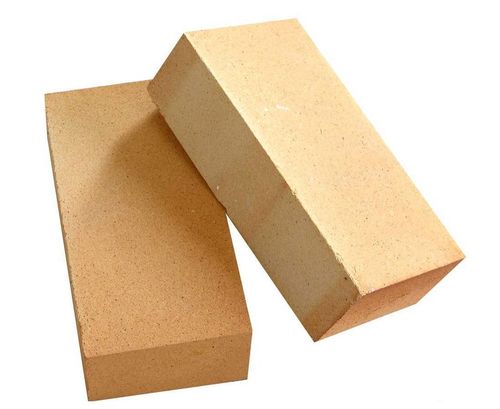

Acid Proof Bricks

Price Range 0.15 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Refractories

Shape : Brick

Acid Resistant Bricks

Price Range - 2.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Refractories

Shape : Brick

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry