Calcium Silicate Boards

Calcium Silicate Boards Specification

- Usage & Applications

- Thermal insulation, fire protection, construction, marine, petrochemical industries

- Water Absorption

- Below 45%

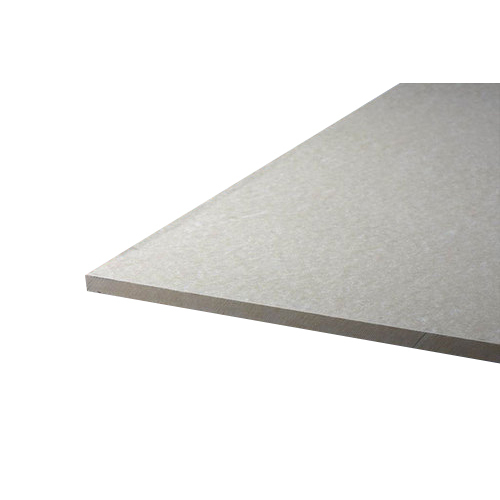

- Surface Finish

- Smooth

- Form

- Board

- Density

- 1000 Gram per cubic centimeter(g/cm3)

- Application

- Wall partition, false ceiling, duct covering, fireproofing, high-temperature insulation

- Hardness (%)

- Above 90%

- Purity(%)

- Above 90%

- Chemical Composition

- Calcium Silicate, minor components (silica, lime, reinforcing fibers)

- Melting Point

- 1000C - 1100C

- Product Type

- Refractories

- Types of Refractories

- Insulating Refractory

- Shape

- Rectangular boards or panels

- Porosity

- High (approx. 8090%)

- Dimensional Stability

- High dimensional stability under temperature fluctuations

- Strength

- Flexural strength: 5 8 MPa

- Specific Gravity

- 0.85 1.0

- Thermal Conductivity

- 0.035 0.11 W/mK

- Color

- White to off-white

- Edge Type

- Square or tapered edge

- pH Value

- Neutral to alkaline (7 10)

- Compressive Strength

- 2.5 6.0 MPa

- Thickness

- 6 mm to 50 mm (common range)

- Sound Insulation

- Up to 35 dB (depending on thickness)

- Moisture Content

- 10%

- Fire Resistance

- Non-combustible, conforms to IS 976:1963, Class 1 & 2 fireproofing

- Service Temperature

- Up to 1000C continuous exposure

- Length x Width

- Usually 1220 x 2440 mm or as specified

Calcium Silicate Boards Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Western Union, Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

About Calcium Silicate Boards

Calcium Silicate Boards

Superior Fire Protection and Thermal Insulation

Designed to meet stringent fire safety standards, Calcium Silicate Boards deliver outstanding fire resistance. Tested to IS 976:1963 Class 1 & 2 specifications, these non-combustible boards tolerate continuous exposure up to 1000C. Their high thermal stability and low thermal conductivity (0.035-0.11 W/mK) ensure reliable insulation, keeping premises safe and efficient even in high-temperature environments.

Structural Reliability and Dimensional Accuracy

Calcium Silicate Boards maintain excellent dimensional stability under temperature fluctuations, thanks to their engineered porosity and density (approximately 1000 g/cm3). Square or tapered edges enhance installation versatility, while the smooth surface and sturdy construction give both aesthetic appeal and practical resilience. Available in various thicknesses and sizes, they deliver superior structural support in diverse environments.

Multifunctional Applications Across Industries

With a combination of fire protection, acoustic insulation (up to 35 dB), and moisture resistance, Calcium Silicate Boards are a go-to solution for wall partitions, ceilings, duct covering, and specialized insulation. They are widely utilized in construction, marine, petrochemical, and industrial settings for exporter, manufacturer, and supplier needs across India.

FAQ's of Calcium Silicate Boards:

Q: How are Calcium Silicate Boards typically installed in construction projects?

A: Calcium Silicate Boards can be cut and fixed using screws or mechanical fasteners to metal or wooden framing systems. Square or tapered edges facilitate easy joint flushness and finishing. Proper joint treatment and priming are recommended for applications like wall partitions and false ceilings.Q: What benefits do Calcium Silicate Boards offer for fireproofing and high-temperature insulation?

A: Owing to their non-combustibility, conforming to IS 976:1963 Class 1 & 2, and a service temperature up to 1000C, Calcium Silicate Boards provide outstanding fire protection. Their low thermal conductivity and high dimensional stability further ensure dependable insulation in environments facing extreme heat.Q: When should Calcium Silicate Boards be chosen over other insulation materials?

A: These boards are ideal whenever fire safety, thermal insulation, and acoustic control are critical-especially in areas requiring frequent exposure to high temperatures and stringent fireproofing, such as duct coverings, marine insulation, or industrial partitions.Q: Where are Calcium Silicate Boards most commonly used?

A: Calcium Silicate Boards see extensive usage in commercial and industrial construction, marine vessels, petrochemical plants, and areas requiring sound insulation. They are indispensable for wall partitions, ceilings, and duct insulation, particularly where fire resistance is mandatory.Q: What is the process for maintaining Calcium Silicate Boards over time?

A: Routine inspection for mechanical damage and moisture ingress is recommended. Due to their low moisture content ( 10%) and high hardness, these boards require minimal regular maintenance-typically limited to cleaning and prompt repair of any damaged sections.Q: What usage advantages do Calcium Silicate Boards have in terms of health and environment?

A: With a neutral to alkaline pH (7-10), high purity (above 90%), and being asbestos-free, Calcium Silicate Boards are safe for indoor environments. Their durable, non-toxic composition supports healthy air quality and complies with environmental safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in insulating and Castables Products Category

Ultra Low Cement Castables

Price Range 100.00 - 800.00 USD ($) / Metric Ton

Price 100.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 Metric Tons

Melting Point : 1700 1800C

Strength : High mechanical strength, Cold Crushing Strength (CCS) > 110 MPa after firing

Hardness (%) : High hardness, above 90%

Low Cement Castables

Price Range 100.00 - 800.00 USD ($) / Metric Ton

Price 100.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Melting Point : Above 1700C

Strength : High cold crushing strength (60100 MPa at 110C)

Hardness (%) : Above 98%

Conventional Castable Powder

Price 100.00 USD ($) / Metric Ton

Minimum Order Quantity : 25 MT Metric Tons

Melting Point : 1600C 1800C

Strength : High Cold Crushing Strength (CCS)

Hardness (%) : Above 90%

Dense Castable

Price Range 100.00 - 500.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 Metric Tons

Melting Point : 1800C 1850C

Strength : 60 70 kg/cm (Cold Crushing Strength)

Hardness (%) : 65 70%

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry