Fire Clay Bricks

Fire Clay Bricks Specification

- Form

- Solid brick

- Chemical Composition

- Al2O3 30-45%, SiO2 50-65%, Fe2O3 < 3%

- Hardness (%)

- 80 - 95

- Water Absorption

- 15 - 20%

- Density

- 2.0 Gram per cubic centimeter(g/cm3)

- Surface Finish

- Smooth

- Purity(%)

- Al2O3 30-45%

- Melting Point

- Approx. 1400C - 1750C

- Application

- Furnaces, Kilns, Incinerators, Chimneys, Boiler linings

- Usage & Applications

- Ideal for construction of lining in furnaces, chimneys, boilers, and other high-temperature industrial applications.

- Product Type

- Refractories

- Types of Refractories

- Fire Clay Refractory

- Shape

- Rectangular (standard and custom shapes available)

- Porosity

- 20 - 28%

- Dimensional Stability

- High, retains shape at elevated temperatures

- Strength

- Cold Crushing Strength 250 - 400 kg/cm2

- Specific Gravity

- 2.1 - 2.5

- Thermal Conductivity

- 1.0 - 1.3 W/mK at 1000C

- Color

- Buff to Light Brown

- Color Uniformity

- Consistent across lots

- Service Temperature

- Up to 1400-1500C continuous

- Refractoriness Under Load (RUL)

- 1200C

- Moisture Content

- 1% by weight

- Size

- Standard size 230mm x 115mm x 75mm (custom sizes available)

- Fire Resistance

- Excellent (up to 1700C depending on composition)

- Bulk Density

- 2.1-2.3 g/cm

- Alumina Content

- 24-40% (varies with grade)

- Cold Crushing Strength

- 350 kg/cm

- Apparent Porosity

- 20-22%

- Silica Content

- 50-65%

Fire Clay Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, North America, South America, Eastern Europe, Middle East, Central America, Asia, Australia, Africa

About Fire Clay Bricks

Fire Clay Bricks

High Performance in Extreme Temperatures

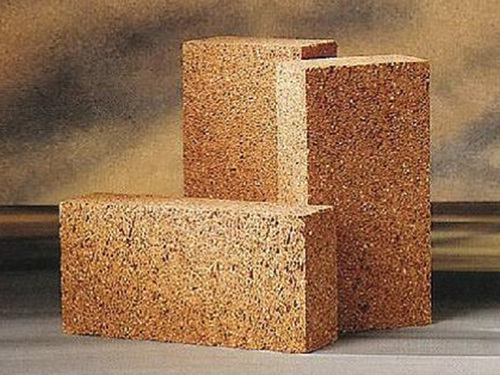

Fire Clay Bricks are recognized for their outstanding ability to withstand continuous service temperatures between 1400C and 1500C. Their refractoriness under load (RUL) exceeds 1200C, ensuring they retain shape and integrity even in the most demanding industrial applications such as furnaces and kilns.

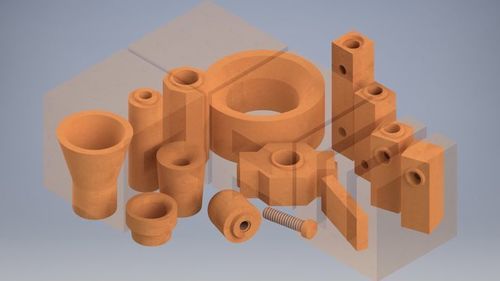

Precision Engineering and Customization

Available in the standard size of 230mm x 115mm x 75mm, and customizable for tailored projects, these bricks are manufactured to exacting standards. Uniform color, smooth finish, and consistent batch quality make them highly reliable for both small- and large-scale projects.

FAQs of Fire Clay Bricks:

Q: What are Fire Clay Bricks typically used for?

A: Fire Clay Bricks are commonly used for lining furnaces, kilns, incinerators, chimneys, and boilers in industries requiring excellent thermal resistance and durability. They serve as a protective layer, ensuring structural integrity during prolonged high-temperature operations.Q: How do Fire Clay Bricks perform under continuous high temperatures?

A: These bricks offer remarkable performance at continuous operating temperatures up to 1400-1500C. Their excellent fire resistance (up to 1700C depending on composition) and high dimensional stability prevent distortion and degradation over time.Q: What process is followed in manufacturing Fire Clay Bricks?

A: Fire Clay Bricks are produced by combining specific proportions of alumina and silica with other select minerals, shaping them into forms, and firing them at high temperatures. This process ensures optimal cold crushing strength, low porosity, and consistent color across batches.Q: Where can these Fire Clay Bricks be installed?

A: They are suitable for a variety of high-temperature environments, including industrial furnaces, chimneys, industrial boilers, and kilns. Custom sizes and shapes are also available for unique installation requirements.Q: What benefits do Fire Clay Bricks provide compared to other refractory materials?

A: These bricks offer a balance of durability, thermal stability, and chemical resistance, making them cost-effective and long-lasting solutions. High cold crushing strength and low moisture content also contribute to their structural reliability during prolonged use.Q: How do I select the right grade or size of Fire Clay Bricks for my application?

A: Selection depends on your process temperature, chemical atmosphere, and physical requirements. Standard size is 230mm x 115mm x 75mm, but custom sizes and grades with variable alumina and silica content are available to match specific operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Bottom Pouring Sets

Price Range 40.00 - 160.00 USD ($) / Metric Ton

Minimum Order Quantity : 400 Metric Tons

Hardness (%) : Approx. 65% 70%

Form : Sets/Built assemblies

Dimensional Stability : Other, High dimensional stability at elevated temperatures

Chemical Composition : Al2O3, SiO2, CaO, Fe2O3; AluminoSilicates

Magnesite Bricks

Price Range 2.00 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Hardness (%) : Above 95%

Form : Solid Bricks

Dimensional Stability : Other, Excellent at high temperature

Chemical Composition : MgO (Magnesium Oxide): 8595%, SiO2: 36%, Fe2O3: 12%

Silicon Carbide Brick

Price Range 2.00 - 10.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Hardness (%) : Mohs hardness 9

Form : Solid brick, standard & custom sizes

Dimensional Stability : Other, Excellent at high temperatures

Chemical Composition : Silicon Carbide (SiC), minor binders

Insulation Bricks

Price Range 1.00 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Hardness (%) : 5060%

Form : Solid

Dimensional Stability : Other, Excellent under high temperatures

Chemical Composition : Al2O3 (Alumina), SiO2 (Silica)

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry