Calcined Bauxite

Calcined Bauxite Specification

- Hardness (%)

- Mohs Hardness 8 - 8.5

- Usage & Applications

- Steel, Cement, Glass Industries, Road Construction

- Form

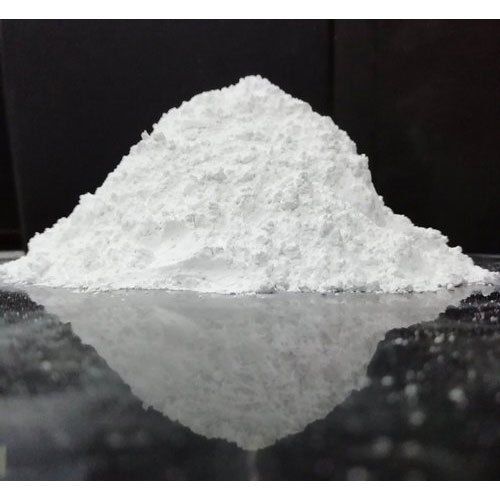

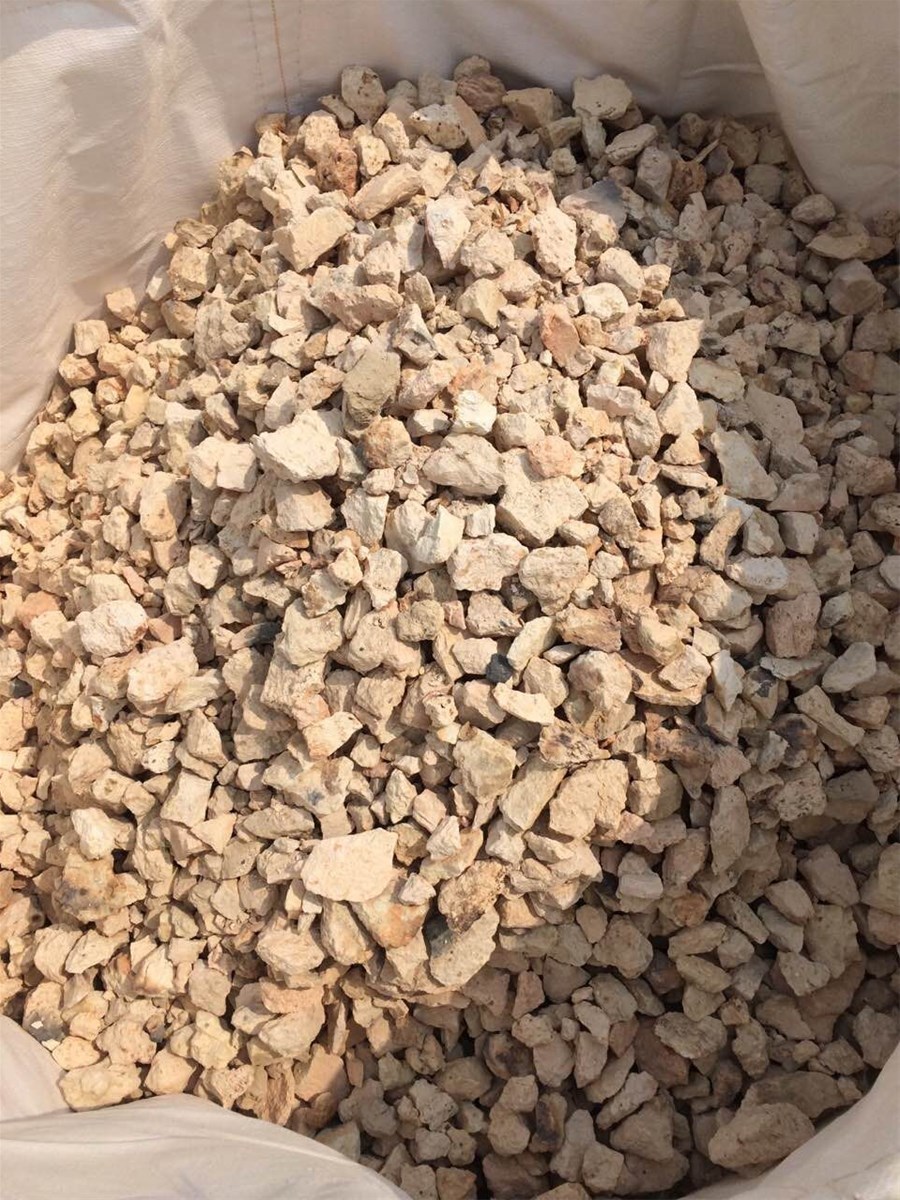

- Lump, Powder, Granules

- Surface Finish

- Rough to Granular

- Melting Point

- 1780C - 1850C

- Chemical Composition

- Al2O3: 80-88%, Fe2O3: 2-4%, TiO2: 2-4%, SiO2: 4-6%

- Water Absorption

- <1%

- Application

- Abrasives, Refractories, Sand Blasting, Road Surfacing, Steel Plants, Furnace Linings

- Density

- 3.10 Gram per cubic centimeter(g/cm3)

- Purity(%)

- 80-88%

- Product Type

- Refractories

- Types of Refractories

- Calcined Bauxite Refractories

- Shape

- Grains, Powder, Lumps

- Porosity

- Low

- Dimensional Stability

- Excellent at High Temperatures

- Strength

- High Crushing Strength

- Specific Gravity

- 3.45 - 3.50 g/cm

- Thermal Conductivity

- Moderate to High

- Color

- Brown, Grey

- Thermal Expansion

- Low

- Abrasion Resistance

- Excellent

- Shelf Life

- Long, Stable Storage

- Bulk Density

- 1.40 - 1.60 T/m³

- Refractoriness Under Load (RUL)

- >1500°C

- Particle Size

- 0-1mm, 1-3mm, 3-5mm, 5-10mm or customized

- Packaging

- 25/50 kg HDPE bags or as required

- State

- Solid

- Grain Size

- As per requirement

Calcined Bauxite Trade Information

- Minimum Order Quantity

- 20 MT Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Western Union, Delivery Point (DP), Telegraphic Transfer (T/T), Days after Acceptance (DA)

- Supply Ability

- 500 Metric Tons Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, North America, Australia, Africa

About Calcined Bauxite

Calcined Bauxite

High-Performance Properties

Calcined Bauxite offers excellent refractoriness under load (>1500C), high crushing strength, and low water absorption (<1%). Its specific gravity ranges from 3.45 to 3.50 g/cm3, and it is renowned for outstanding abrasion resistance and low porosity. These attributes make it suitable for extreme industrial environments and challenging applications.

Versatile Particle Sizes & Forms

Our Calcined Bauxite is available in customizable grain sizes (0-1mm, 1-3mm, 3-5mm, 5-10mm) and in multiple shapes, such as lumps, powder, and granules. The varying forms allow tailored solutions for diverse processes, from abrasives and refractories to sand blasting and road construction.

Reliable Packaging & Long Shelf Life

To ensure safety and ease of handling, Calcined Bauxite is packaged in high-quality HDPE bags of 25 or 50 kg, or per customer requirements. Its stable storage and long shelf life guarantee consistent performance and reduce material wastage over time.

FAQ's of Calcined Bauxite:

Q: How is Calcined Bauxite used in steel and cement industries?

A: Calcined Bauxite is employed as a raw material in the production of refractory linings, which protect furnaces and kilns from high temperatures and abrasion in steel and cement plants. Its high Al2O3 content and crushing strength help extend the operational life of these industrial linings.Q: What is the process for customizing particle size or grain size of Calcined Bauxite?

A: We offer Calcined Bauxite in standard sizes ranging from 0-1mm up to 5-10mm, and can customize grain size based on specific customer requirements, ensuring optimal performance for intended applications. The material is processed and screened to achieve consistency and precision in sizing.Q: What benefits does Calcined Bauxite provide in road surfacing and construction?

A: Calcined Bauxite's excellent abrasion resistance, high hardness (Mohs 8-8.5), and rough granular surface ensure long-lasting, non-slip roads. It supports improved durability and safety in both standard and high-traffic construction scenarios due to its dimensional stability and low porosity.Q: When should Calcined Bauxite be applied for refractory purposes?

A: Calcined Bauxite is recommended for refractory applications when extreme temperatures, above 1500C, and high mechanical strength are required. Its stability and low thermal expansion make it a preferred choice for critical furnace, kiln, and similar high-heat environments.Q: Where is Calcined Bauxite sourced and supplied from?

A: Calcined Bauxite is manufactured, exported, and supplied by verified producers in India, ensuring reliable quality and timely global delivery for industrial customers.Q: What are the recommended packaging options for Calcined Bauxite?

A: Calcined Bauxite is securely packed in 25 kg or 50 kg HDPE bags, or according to client requirements. This packaging ensures material integrity, safety in handling, and ease of transportation.Q: How does the low thermal expansion of Calcined Bauxite benefit different industrial applications?

A: Low thermal expansion in Calcined Bauxite reduces the risk of cracking or structural failure during rapid temperature changes, making it ideal for refractory linings, furnace parts, and other high-temperature industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Minerals Category

Feldspar Lumps

Price Range 35.00 - 150.00 USD ($) / Metric Ton

Minimum Order Quantity : 27 Metric Tons

Application : ceramic , tiles ,glass

Product Type : Minerals

Attapulgite Clay API 13A Section 12

Price Range 140.00 - 390.00 USD ($) / Metric Ton

Minimum Order Quantity : 27 Metric Tons

Application : Industrial, medicinal, thixotrope for coatings, adhesives, paint fertilizers, industrial absorbents

Product Type : Minerals

Quartz Powder

Price 210 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : oil well drilling, glass making , watches , foundry , refactory industry , petroleum industry , ceramic

Product Type : Minerals

Silica Sand Crystal

Price 210 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : foundry , glass , chemical

Product Type : Minerals

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry