Fire Clay

MOQ : 20 MT Metric Tons

Fire Clay Specification

- Hardness (%)

- Up to 90%

- Chemical Composition

- Al2O3 (30-45%), SiO2 (50-60%), Fe2O3 (<2%), TiO2 (<1%)

- Usage & Applications

- Steel, glass, cement, power generation, ceramic, and chemical industries

- Density

- 2.10 Gram per cubic centimeter(g/cm3)

- Melting Point

- 1440C - 1780C

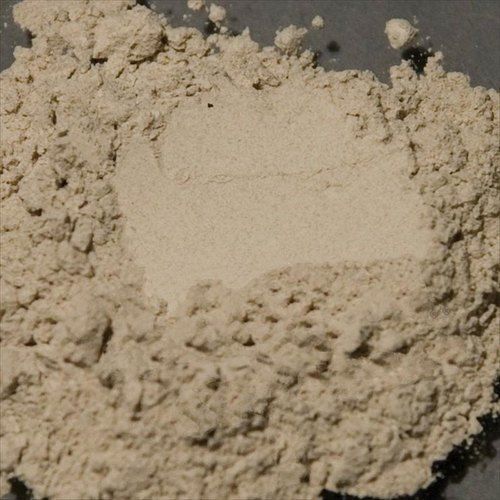

- Form

- Powder, Brick, Lump

- Surface Finish

- Granular, coarse or smooth (depending on processing)

- Water Absorption

- 10 - 14%

- Purity(%)

- 30-45% Al2O3, high purity option available

- Application

- Refractory linings, furnace construction, kilns, foundry, boiler work, incinerators

- Product Type

- Refractories

- Types of Refractories

- Fire clay refractory

- Shape

- Powder, lumps, bricks

- Porosity

- 18 - 30%

- Dimensional Stability

- Excellent, retains shape at high temperature

- Strength

- High compressive strength, excellent structural integrity under high temperature

- Specific Gravity

- 2.35 - 2.50

- Thermal Conductivity

- Low (0.81.2 W/mK at 1000C)

- Color

- Light brown to yellowish

Fire Clay Trade Information

- Minimum Order Quantity

- 20 MT Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 500 Metric Tons Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia

About Fire Clay

Fire Clay

Offered alumina Fire Clay Powder is a type of refractory mortar which is used as suitable joint filler. Excellent plasticity level, unique liquidity level, good adhesive strength and chemical attack resistance capacity are some of its key features. Provided Fire Clay Powder is appreciated for its low thermal co-efficiency level, minimal shrinkage rate at high temperature and stable volume. Standard of this powder can resist slag and its gas tightness deserves praise. Excellent mechanical strength and unique thermal performance are its main aspects.

Highly Resistant and Adaptable Fire Clay

Our fire clay offers excellent refractoriness under load, withstanding temperatures up to 1350C at 0.2 MPa, and displays minimal shrinkage (<2%) at 1400C. The material's low porosity (18-30%) and robust cold crushing strength make it suitable for various thermal applications, ensuring both safety and durability in intense conditions.

Custom Particle Size and Versatile Forms

We provide fire clay in powder, lump, or brick form, with customizable particle sizes as per customer requirements. The clay's surface finish can be tailored-granular, coarse, or smooth-optimizing it for specific industrial usage from furnace construction to foundry and boiler applications.

Superior Quality and Safe Packaging

Our fire clay is packaged in 25/50 kg HDPE bags or as specified, ensuring protection from moisture during transport and storage. Its high purity option and excellent thermal shock resistance guarantee longevity and efficient performance, particularly vital for frequent heating and cooling cycles in make-intensive industry environments.

FAQ's of Fire Clay:

Q: How is fire clay used in industrial refractory applications?

A: Fire clay is commonly used in refractory linings for furnaces, kilns, incinerators, and boiler work due to its high refractoriness, excellent structural integrity at elevated temperatures, and resistance to thermal shock. Its customizable particle size and versatile form factors make it suitable for steel, glass, cement, ceramic, and chemical industries.Q: What benefits does customizable particle size offer for fire clay?

A: Customizable particle size allows fire clay to meet specific process requirements, improving packing density, thermal conductivity, and surface finish. This leads to optimized performance in applications such as furnace linings, foundries, and boiler work, enhancing durability and efficiency.Q: When should I choose fire clay with high compressive strength and thermal shock resistance?

A: You should select fire clay with high compressive strength (180-250 kg/cm2) and excellent thermal shock resistance for environments where materials endure frequent heating and cooling cycles or high mechanical loads, such as incinerators, industrial kilns, and power generation setups.Q: Where can fire clay be stored to maintain its quality?

A: Fire clay should be stored in a dry, covered area away from moisture and contaminants. Proper storage in HDPE bags or designated containers preserves its chemical properties, particle integrity, and prevents unwanted reactions due to water absorption.Q: What is the process for ordering fire clay with custom specifications?

A: Customers can specify particle size, form (powder, lump, brick), and packaging requirements when placing orders. Manufacturers provide tailored solutions to suit volume, purity, and usage needs, supporting various industrial applications across India and for export.Q: How does fire clay's chemical composition improve its performance in refractory environments?

A: The balanced composition of Al2O3 (30-45%), SiO2 (50-60%), and minimal impurities (Fe2O3 <2%, TiO2 <1%) ensures high purity, refractoriness, and structural integrity. This mix supports low shrinkage and high dimensional stability at elevated temperatures, minimizing the risk of failure during thermal cycling.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Clay-Based Refractoriees Category

Ball Clay

Price Range 20.00 - 90.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Strength : High plasticity and bonding strength

Application : Ceramics, Refractories, Sanitary ware, Tiles, Pottery

Shape : Other, Powder or lumps

Silica Clay

Price 210 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Strength : 10001200C

Application : Paints

Shape : Other, Powdered

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry