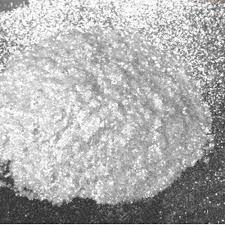

Silica Sand Powder

Price 350.00 USD ($)/ Metric Ton

Silica Sand Powder Specification

- Application

- foundry , glass , chemical

- Product Type

- Minerals

Silica Sand Powder Trade Information

- Minimum Order Quantity

- 28 Metric Tons

- Payment Terms

- Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Days after Acceptance (DA)

- Delivery Time

- 5 Days

- Packaging Details

- WE PROVIDE 25KG, 50KG PP BAGS, WE ALSO PROVIDE CUSTOMIZED PACKAGING AND PRINTING OPTIONS IN ALL SIZES

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

About Silica Sand Powder

High Purity and Consistency

Our silica sand powder is processed to achieve exceptionally high purity (99%) and reliable chemical composition, ensuring less than 1% moisture and more than 98% SiO2. This results in a product that meets the stringent requirements of glass and foundry industries, providing both quality and efficiency.

Versatile Applications Across Industries

This silica sand powder is perfectly suited for a range of applications including glass manufacturing, foundries, and the chemical sector. Its fine particle size and high whiteness also make it a preferred choice for industries requiring uniformity and aesthetic appeal.

FAQ's of Silica Sand Powder:

Q: How is the silica sand powder processed to achieve a 200 mesh average particle size?

A: The silica sand powder is processed using advanced grinding and sieving techniques to ensure a consistent average particle size of 200 mesh, resulting in a fine, uniform powder ideal for industrial applications.Q: What benefits does the high purity (99%) of this silica sand offer for glass and foundry applications?

A: The high purity level greatly reduces impurities in the final product, ensuring optimal chemical reactions in glass making and consistent casting quality in foundry operations. This leads to enhanced product strength and clarity.Q: When should I use this silica sand powder in comparison to coarser sand types?

A: This fine, 200 mesh silica sand powder is best used when a smooth surface finish, high reactivity, or precision casting is required, such as in high-quality glass production or intricate foundry molds, as opposed to coarser sands typically used in construction.Q: Where is this silica sand powder typically utilized within industrial processes?

A: It is primarily utilized in the glass manufacturing sector for producing clear, high-strength glass, and in foundries for preparing molding mixtures that require detailed, accurate castings. It is also used in certain chemical processes as a key ingredient.Q: What is the typical process for using this silica sand powder in glass manufacturing?

A: In glass manufacturing, the silica sand powder is mixed with other raw materials and melted at high temperatures to form glass. Its high whiteness and purity ensure optimal transparency and structural integrity in the resulting glass products.Q: Is there a benefit to the powder's off-white color and 90%+ whiteness for industrial uses?

A: Yes, the off-white color and high whiteness guarantee minimal coloring impurities, making the powder highly desirable for applications where clarity or aesthetic purity is crucial, such as specialty glass or high-end chemical synthesis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Minerals Category

Acidic Ramming Mass

Minimum Order Quantity : 20 MT Metric Tons

Product Type : Refractories

Application : Lining of induction furnaces for melting metals, especially steel and iron

Chemical Composition : Silica (SiO) > 99%, Trace impurities (Al2O3, Fe2O3, CaO, MgO)

Types of Refractories : Other, Acidic Refractories

Shape : Other, Granular / Powder

Mica Flakes

Product Type : Mica Flakes, Other

Application : Used in plastic rubber paints cosmetics and insulation materials

Chemical Composition : Potassium Aluminum Silicate

Types of Refractories : Other, Nonrefractory

Shape : Other, Irregular flakes

Mica Coarse Powder

Minimum Order Quantity : 27 Metric Tons

Product Type : Minerals

Application : Paints ,Ceramics ,Rubber , Linoleum Flooring

Calcined Kaolin Clay

Minimum Order Quantity : 25 Metric Tons

Product Type : Minerals

Application : "Ceramic body, Vitrified Tiles, Glaze Tile, Sanitary ware, Refractory, White Cement, Gray Cement "

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry