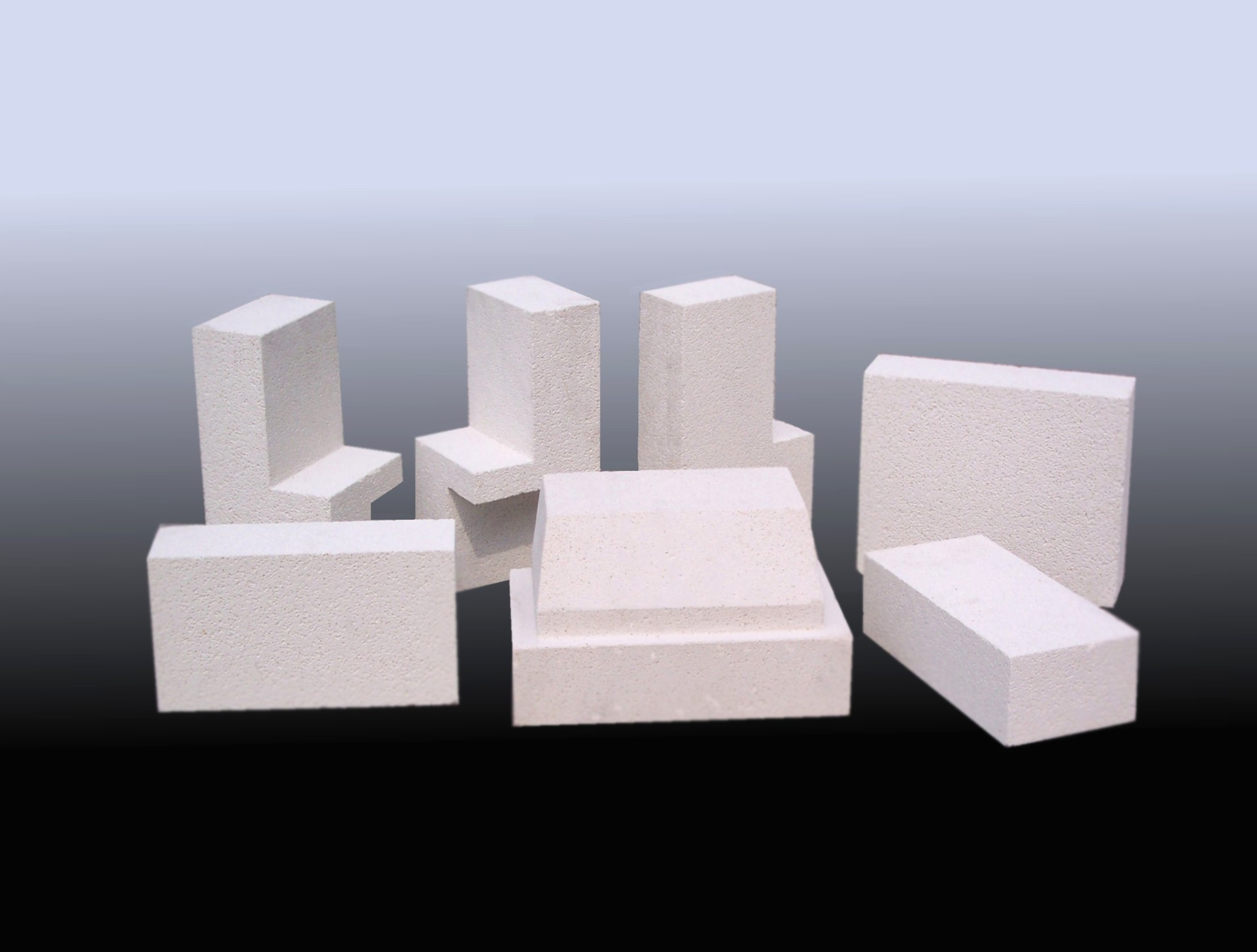

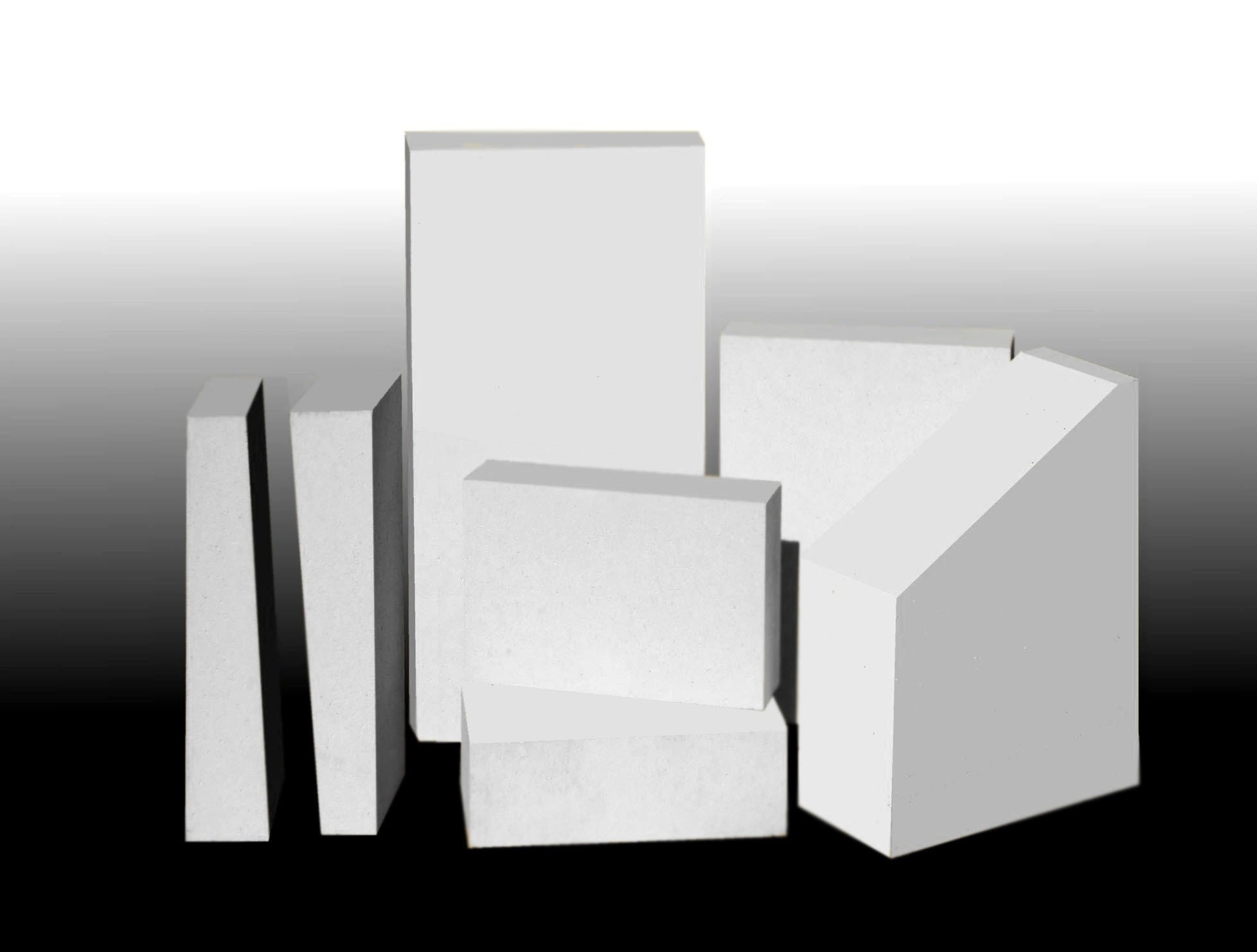

Insulating Fire Bricks

Price 0.50 USD ($)/ Piece

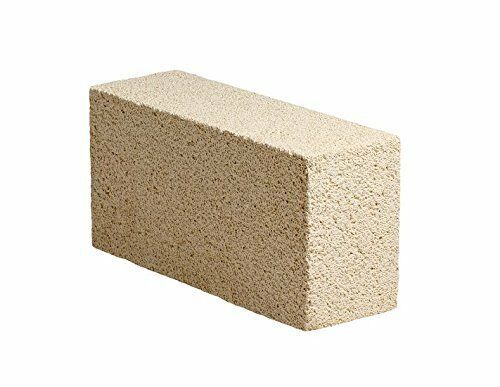

Insulating Fire Bricks Specification

- Purity(%)

- Alumina: 3045%

- Melting Point

- 1780C

- Density

- 1.2 Gram per cubic centimeter(g/cm3)

- Application

- Furnace insulation, Kilns, Fireplaces, Metal Industry, Chemical Plants

- Hardness (%)

- 60 70%

- Form

- Solid brick

- Chemical Composition

- Alumina-Silicate

- Surface Finish

- Smooth/matt

- Water Absorption

- 3550%

- Usage & Applications

- Ideal for thermal insulation in industrial furnaces and kilns

- Product Type

- Refractories

- Types of Refractories

- Insulating Refractory Brick

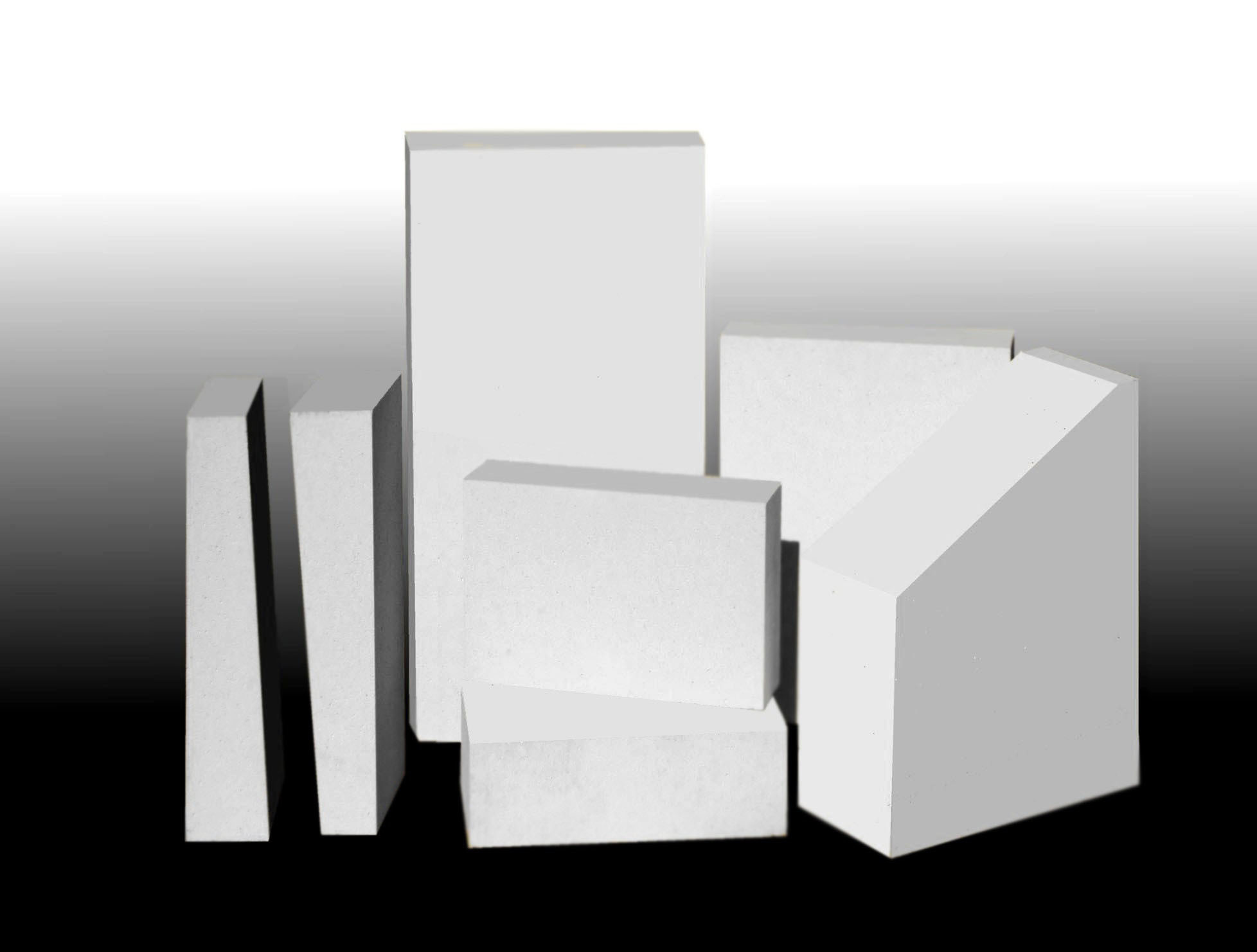

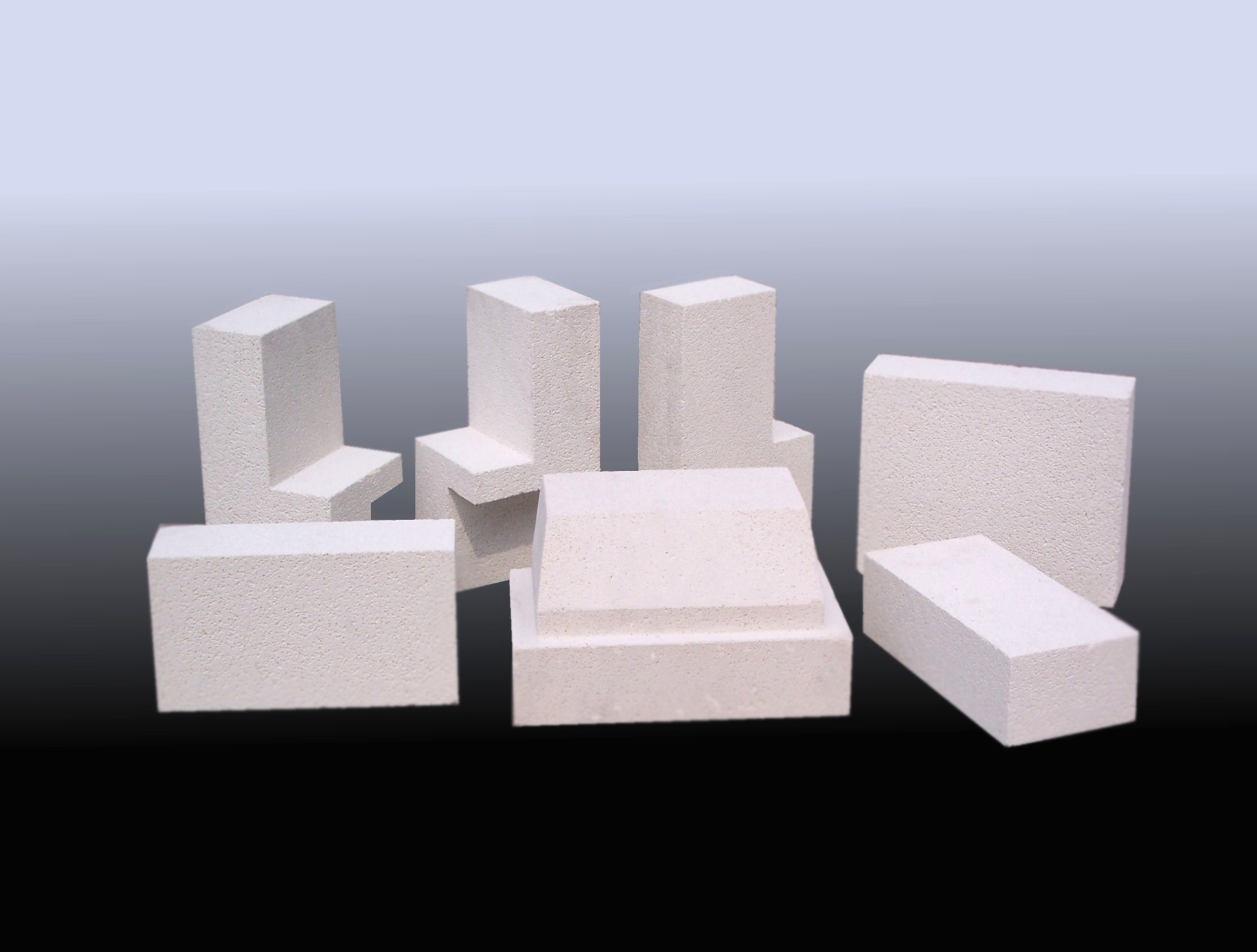

- Shape

- Rectangular brick

- Porosity

- High

- Dimensional Stability

- Excellent at high temperatures

- Strength

- Cold Crushing Strength: 15-35 kg/cm

- Specific Gravity

- 1.3 1.5

- Thermal Conductivity

- Low, typically 0.20.45 W/mK

- Color

- Light cream/white

- Thermal Expansion

- Low

- Insulation Rating

- Highly energy efficient

- Compressibility

- Rigid

- Fire Resistance

- Excellent resistance to thermal shocks

- Bulk Density

- 0.91.2 g/cm

- Shelf Life

- Unlimited when stored dry

- Packing

- Shrink-wrapped or carton box

- Acid Resistance

- Resistant to common acids

- Size

- Standard: 230 x 114 x 76 mm (custom sizes available)

- Manufacturing Method

- Pressed and fired

- Service Temperature

- Up to 1200C

- Flexural Strength

- 7 kg/cm

Insulating Fire Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Western Union, Delivery Point (DP), Telegraphic Transfer (T/T), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Asia, Australia, South America, Eastern Europe, Middle East, Africa, Central America, North America

About Insulating Fire Bricks

Insulating Fire Bricks

Superior Thermal Insulation for Industrial Applications

These insulating fire bricks deliver outstanding performance in high-temperature environments, such as furnaces, kilns, and fireplaces. Their high alumina content and robust manufacturing process ensure low thermal conductivity, making them highly energy efficient. Their light cream or white color indicates purity, and high porosity further enhances insulation efficiency while resisting thermal shocks and maintaining structural integrity under stress.

Versatile and Durable Construction Material

Engineered with a blend of alumina and silicate, these bricks are pressed, fired, and shaped to provide utmost durability and chemical resistance. With a specific gravity of 1.3 - 1.5 and cold crushing strength of 15-35 kg/cm2, they are capable of withstanding frequent thermal cycling. Their rigid and dimensional stability at elevated temperatures enables reliable, long-term use in diverse industrial applications.

FAQ's of Insulating Fire Bricks:

Q: How do insulating fire bricks contribute to energy efficiency in industrial settings?

A: These bricks have low thermal conductivity (typically 0.2-0.45 W/mK), which minimizes heat loss and maintains consistent temperatures within furnaces and kilns, resulting in significant energy savings during operation.Q: What is the best process for installing these insulating fire bricks in a furnace or kiln?

A: Ensure the inner surface is clean and dry before installation. Position bricks tightly in place, using appropriate refractory mortar if required. Custom sizing is available for specialized layouts, and shrink-wrapped or carton packaging protects bricks during transport and storage.Q: When should I consider using insulating fire bricks over dense fire bricks?

A: Opt for insulating fire bricks when the primary goal is to reduce heat loss and enhance energy efficiency, particularly in applications with service temperatures up to 1200C-such as kilns, furnaces, or fireplaces-where thermal insulation is crucial.Q: Where can these insulating fire bricks be applied?

A: They are ideal for use in industrial furnaces, kilns, fireplaces, and metal or chemical processing plants. Their versatility and resistance to acids make them suitable for a broad range of high-temperature industrial environments.Q: What benefits do these bricks offer in terms of durability and chemical resistance?

A: With a cold crushing strength of 15-35 kg/cm2 and resistance to common acids, these bricks provide long-lasting performance, even in demanding chemical or thermal environments, reducing maintenance needs.Q: How does the brick's composition affect its performance at high temperatures?

A: The alumina-silicate composition and high purity (30-45% alumina) guarantee excellent dimensional stability, low thermal expansion, and outstanding resistance to thermal shocks while retaining strength at elevated temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Alumina Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : 98%

Melting Point : 18001900C approx.

Thermal Conductivity : Good (varies with composition)

Types of Refractories : Basic Refractory

Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : Above 97%

Melting Point : 2800C (approx.)

Thermal Conductivity : High

Types of Refractories : Basic Refractory

Silica Bricks

Price Range 1.50 - 3.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : SiO2 > 95%

Melting Point : 1710C

Thermal Conductivity : 1.01.2 W/mK

Types of Refractories : Acid Refractory

Silicon Carbide Brick

Price Range 2.00 - 10.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Purity(%) : 98%

Melting Point : 2200C 2400C

Thermal Conductivity : High (10 16 W/mK)

Types of Refractories : Other, High alumina, oxidebonded, nitridebonded

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry