Magnesia Carbon Bricks

Magnesia Carbon Bricks Specification

- Hardness (%)

- 85%

- Usage & Applications

- Steel Industry, ladle lining, converters, electric arc furnace walls and roofs

- Surface Finish

- Smooth

- Chemical Composition

- MgO > 70%, C = 10-20%

- Form

- Solid Brick

- Water Absorption

- 0.3%

- Density

- 3.1 Gram per cubic centimeter(g/cm3)

- Application

- Steel making furnaces, ladles, converters, EAF lining

- Melting Point

- 2800C (approx.)

- Purity(%)

- Above 97%

- Product Type

- Refractories

- Types of Refractories

- Basic Refractory

- Shape

- Rectangular / Brick-shaped

- Porosity

- Low ( 6%)

- Dimensional Stability

- Excellent at high temperature

- Strength

- Cold Crushing Strength: 25-35 MPa

- Specific Gravity

- 2.9 - 3.0

- Thermal Conductivity

- High

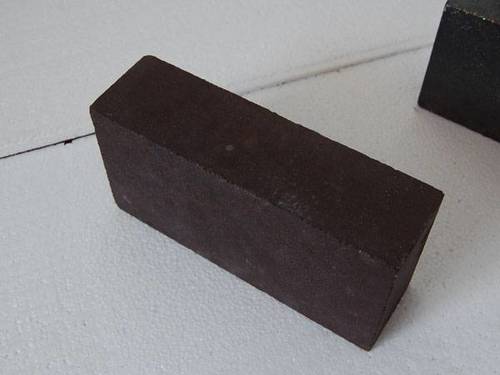

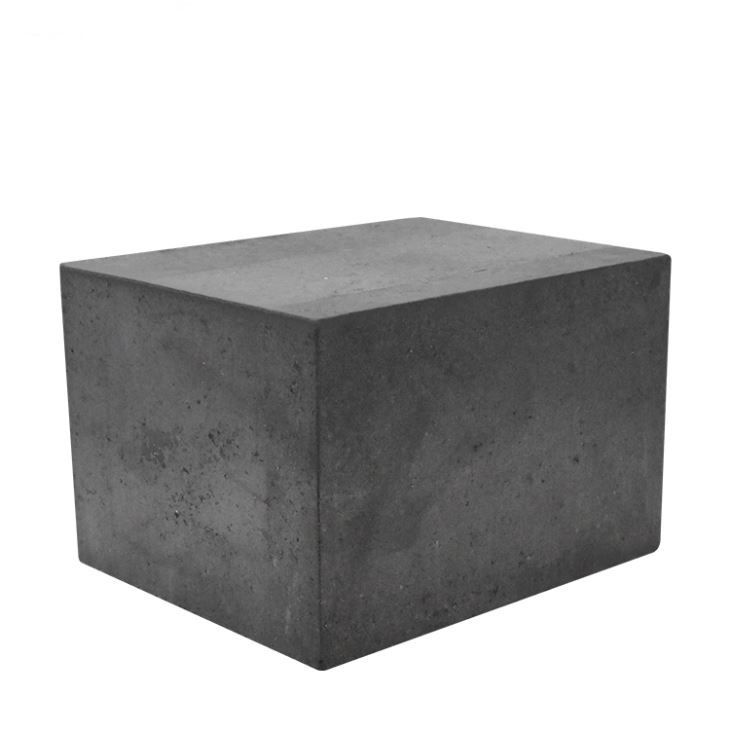

- Color

- Black / Dark Grey

Magnesia Carbon Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, North America, Africa

About Magnesia Carbon Bricks

Magnesia Carbon Bricks

Superior Refractory Performance

Magnesia Carbon Bricks offer excellent performance at high temperatures, with maximum operating temperatures reaching 1800C and a melting point of approximately 2800C. Their robust structure, low porosity, and high thermal conductivity make them essential for demanding thermal applications in steel-making and iron-processing industries.

Exceptional Durability and Strength

Engineered with a cold crushing strength of 25-35 MPa and a modulus of rupture between 6-10 MPa, these bricks withstand mechanical and thermal stresses encountered in furnaces and ladles. The use of phenolic resin as a binding agent further contributes to their longevity and reduces water absorption below 0.3%.

Versatile and Customizable Solutions

Available in standard and customizable sizes, Magnesia Carbon Bricks are well-suited for diverse steel industry usage, including ladle linings, converter walls, and EAF roofs. Their high purity, smooth surface, and excellent dimensional stability enable precise installation and extended refractory service life.

FAQ's of Magnesia Carbon Bricks:

Q: How are Magnesia Carbon Bricks used in steel plants?

A: Magnesia Carbon Bricks are primarily used as lining materials in steel-making furnaces, ladles, converters, and electric arc furnace (EAF) walls and roofs. Their excellent thermal shock and oxidation resistance make them ideal for withstanding the rapid temperature changes and corrosive environments found in steel plants.Q: What benefits do anti-oxidants add to Magnesia Carbon Bricks?

A: Anti-oxidants incorporated into Magnesia Carbon Bricks enhance oxidation resistance, extending brick life during high-temperature operations. They prevent carbon oxidation, thereby maintaining structural integrity and reducing maintenance frequency in aggressive furnace conditions.Q: When should Magnesia Carbon Bricks be selected for industrial applications?

A: These bricks should be chosen when high-temperature resilience, thermal shock resistance, and low porosity are required. Applications such as steel-making, iron manufacturing, and foundry operations benefit from their dimensional stability and resistance to chemical and thermal attack.Q: What is the process for installing Magnesia Carbon Bricks in a furnace lining?

A: Installation involves placing the bricks in the designated area, ensuring close alignment for a strong refractory wall. Phenolic resin binding agent is often used to enhance adhesion, and customized sizes allow for optimal fitting in complex furnace designs, improving thermal insulation and performance.Q: Where can Magnesia Carbon Bricks be sourced or supplied?

A: Magnesia Carbon Bricks are available from exporters, manufacturers, and suppliers in India and globally. Ensuring a reputable supplier guarantees access to bricks with verified chemical composition, mechanical strength, and dimensional accuracy needed for demanding industrial environments.Q: What makes the bricks suitable for service temperatures up to 1800C?

A: Their high MgO content (over 70%) and carbon levels (10-20%), combined with low porosity and high density, enable the bricks to endure extreme temperatures. This ensures reliable operation and longevity in furnaces operating at up to 1800C.Q: How does the low porosity of Magnesia Carbon Bricks benefit furnace applications?

A: Low porosity ( 6%) reduces the risk of slag and gas penetration, improving the longevity and efficiency of furnace linings. This enhances the overall structural performance and minimizes downtime caused by refractory wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Fire Clay Bricks

Price Range - 2.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Refractories

Chemical Composition : Al2O3 3045%, SiO2 5065%, Fe2O3 < 3%

Color : Buff to Light Brown

Form : Solid brick

Mullite Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Refractories

Chemical Composition : Al2O3, SiO2

Color : Off White, Light Brown

Form : Solid Brick

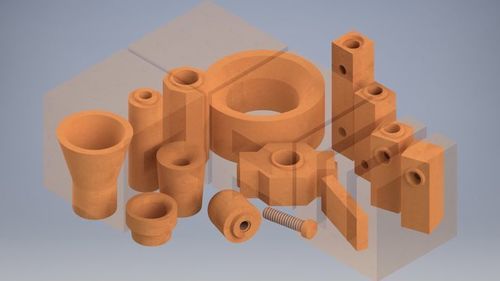

Bottom Pouring Sets

Price Range 40.00 - 160.00 USD ($) / Metric Ton

Minimum Order Quantity : 400 Metric Tons

Product Type : Refractories

Chemical Composition : Al2O3, SiO2, CaO, Fe2O3; AluminoSilicates

Color : Light Brown / Beige

Form : Sets/Built assemblies

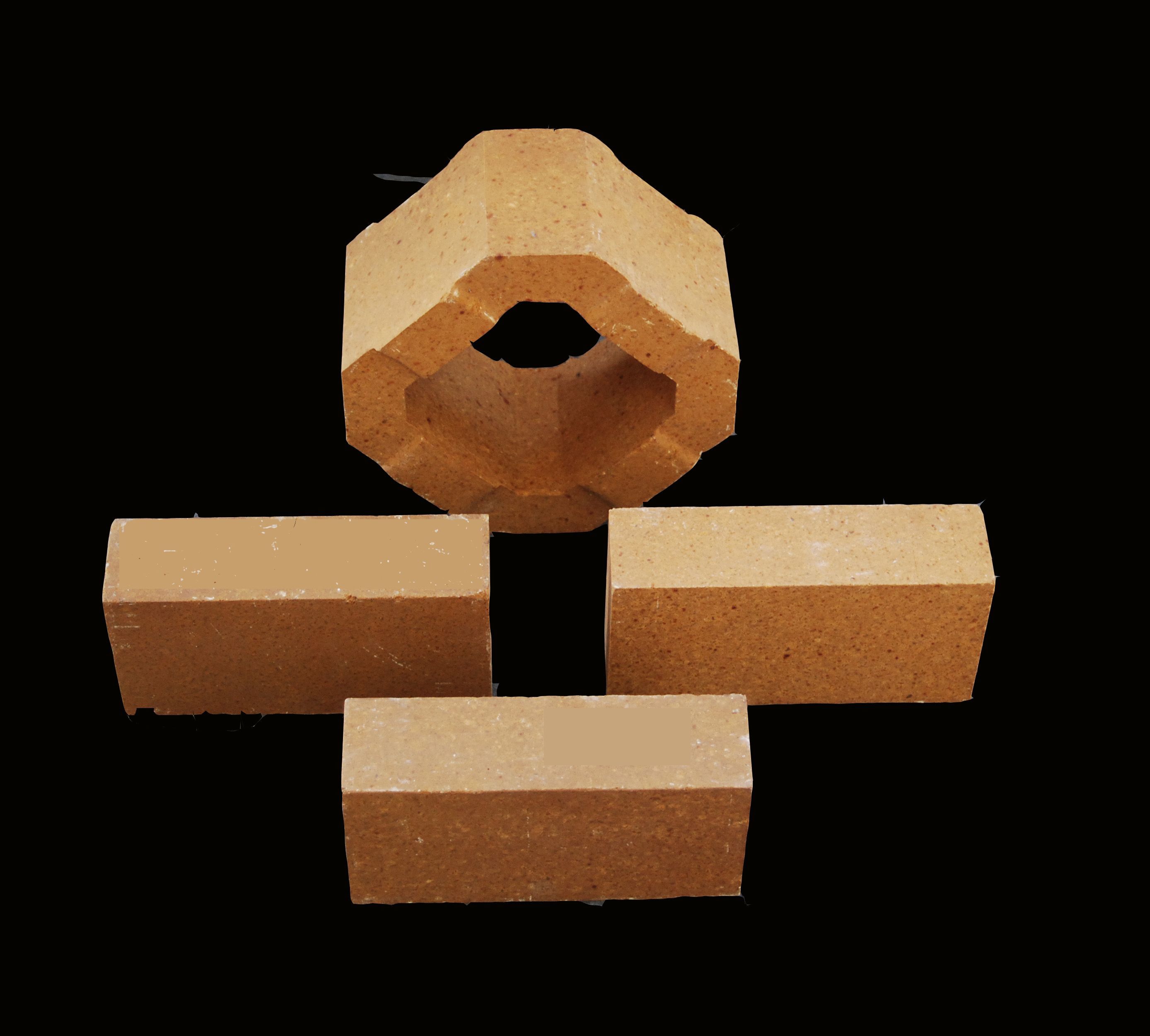

Cupola Bricks

Price Range 0.20 - 0.50 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Refractories

Chemical Composition : High Alumina, Silica, Magnesia

Color : Light Brown/Red

Form : Solid Brick

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry