PCPF Blocks

MOQ : 200 Pieces

PCPF Blocks Specification

- Usage & Applications

- Industrial high-temperature applications, thermal insulation, structural lining

- Form

- Solid Block

- Hardness (%)

- 60%-80%

- Chemical Composition

- Alumina, Silica, Other Additives

- Surface Finish

- Smooth

- Application

- Kilns, Furnaces, Lining, Boilers, Incinerators, Foundries

- Purity(%)

- 85%-98%

- Water Absorption

- 8%-12%

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Melting Point

- 1400C - 1750C

- Product Type

- Refractories

- Types of Refractories

- Fire Clay Bricks, High Alumina Bricks, Insulation Bricks

- Shape

- Rectangular/Custom

- Porosity

- 18%-24%

- Dimensional Stability

- Excellent at High Temperatures

- Strength

- High Cold Crushing Strength

- Specific Gravity

- 1.8 - 2.3

- Thermal Conductivity

- 0.8-1.2 W/mK

- Color

- Light Cream/Off White

PCPF Blocks Trade Information

- Minimum Order Quantity

- 200 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 2000 Pieces Per Month

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe, Asia

About PCPF Blocks

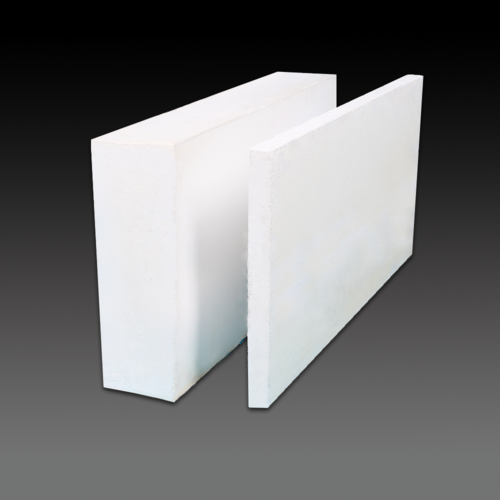

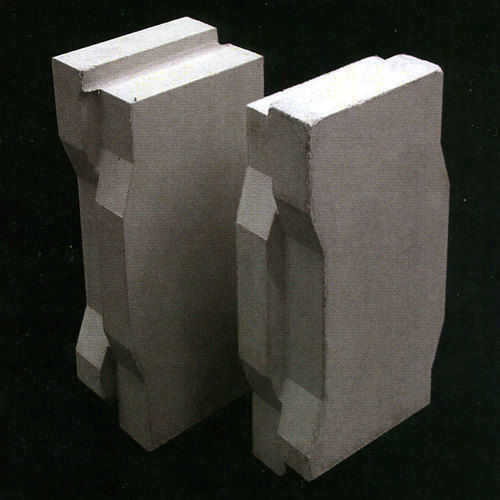

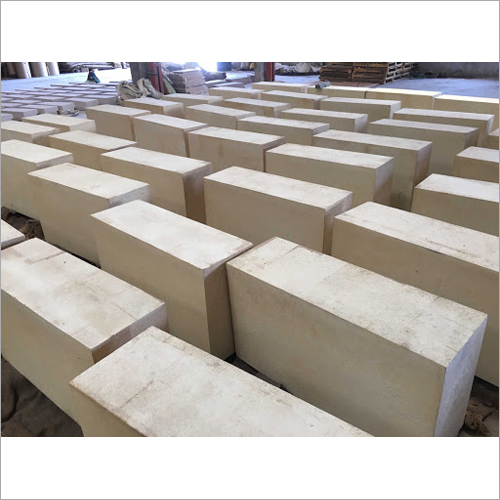

PCPF Blocks

Another refractory item that customers can obtain from us is PCPF blocks for their steel manufacturing units. The pre cast pre fired blocks can resist erosion, wear, corrosion and thermal shocks. With high heat strength, these blocks can be installed and used in simple to critical areas. The durable, abrasion resistant and lasting blocks also find use in construction industry. Customers from cement, iron and other industries can also order from us these blocks in desired shapes, sizes and quantity.

Superior High-Temperature Performance

PCPF Blocks are engineered for excellent durability and performance in extreme heat environments, supporting temperatures up to 1700C. Their high cold crushing strength and robust chemical composition enable them to maintain integrity under mechanical and thermal stress, making them particularly suitable for industrial applications demanding consistent reliability and safety.

Versatile Applications and Customization

These blocks are available in both standard and custom sizes to fit a variety of industrial requirements. Their adaptability makes them ideal for use in kilns, furnaces, boilers, incinerators, and foundries. Their superior thermal insulation, refractoriness under load, and acid resistance optimize them for challenging operating conditions.

Eco-Friendly and Long Lasting

With a composition that is non-hazardous and environmentally responsible, PCPF Blocks are safe for workers and sustainable for the planet. When stored under dry conditions, their impressive shelf life ensures lasting effectiveness and cost-efficiency for both large-scale enterprises and smaller operations.

FAQs of PCPF Blocks:

Q: How are PCPF Blocks used in industrial applications?

A: PCPF Blocks are primarily used for lining and insulating industrial kilns, furnaces, boilers, incinerators, and foundries, providing durable structural support and effective thermal insulation in high-temperature environments.Q: What makes PCPF Blocks suitable for high-temperature operations?

A: Their high cold crushing strength, excellent thermal shock resistance, and refractoriness under load (over 1400C) ensure structural stability and integrity even at temperatures up to 1700C, making them reliable for continuous furnace operations.Q: When should I choose custom sizes over standard PCPF Block sizes?

A: Custom sizes are recommended when your installation requires specific dimensions for optimal fit and performance, ensuring a perfect match for unique equipment designs and maximizing insulation efficiency.Q: Where can I source PCPF Blocks for export or domestic supply in India?

A: PCPF Blocks are available through leading refractory manufacturers, exporters, and suppliers based in India, offering both domestic deliveries and international export options with secure packaging.Q: What is the typical process for installing PCPF Blocks?

A: Installation involves preparing the desired area, lining it with the blocks according to design specifications, and securing them using appropriate refractory mortar or bonding agents to ensure stability and thermal efficiency.Q: What are the benefits of using eco-friendly, non-hazardous PCPF Blocks?

A: These blocks are safe to handle, promote sustainable industrial practices, and help protect both operators and the environment while maintaining high performance and durability in service.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Tiles & Blocks Category

Calcium Silicate Blocks

Price Range 1.50 - 10.00 USD ($) / Piece

Minimum Order Quantity : 200 Pieces

Surface Finish : Smooth or slightly textured

Chemical Composition : Calcium Silicate, inert fillers, and additives

Hardness (%) : High, retains rigidity at high temperatures

Refractory Tiles

Price 0.15 USD ($) / Piece

Minimum Order Quantity : 3000 Pieces

Surface Finish : Smooth

Chemical Composition : Alumina, Silica, Clay

Hardness (%) : >80%

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry