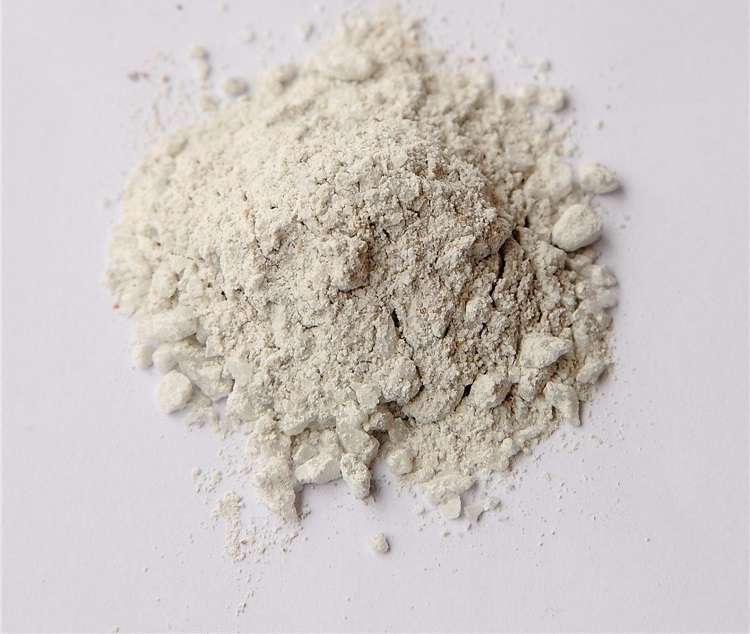

Basic Ramming Mass

Basic Ramming Mass Specification

- Form

- Powder / Granules

- Purity(%)

- 95-98%

- Surface Finish

- Granular / Powdered Finish

- Chemical Composition

- CaO, MgO, SiO2, Fe2O3

- Hardness (%)

- 60-75

- Density

- 2.8 Gram per cubic centimeter(g/cm3)

- Melting Point

- 1700-1800C

- Usage & Applications

- Used for lining of induction furnaces and foundries

- Water Absorption

- Low

- Application

- Steel Industry, Furnace Lining, Iron and Steel Melting

- Product Type

- Refractories

- Types of Refractories

- Basic Refractory

- Shape

- Granule / Powder

- Porosity

- Low

- Dimensional Stability

- Excellent at High Temperature

- Strength

- High Cold Crushing Strength

- Specific Gravity

- 2.70-2.90

- Thermal Conductivity

- Good

- Color

- Off White to Light Grey

Basic Ramming Mass Trade Information

- Minimum Order Quantity

- 20 MT Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 500 Metric Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

About Basic Ramming Mass

Basic Ramming Mass

Basicramming mass are magnesia based refractory mass used as the refractory liningmaterial in the furnaces. Its main characteristics are fine finish, thermalresistance and extended durability. We are a leading Manufacture, Supplier andExporter of Best Quality of Basic ramming mass as per the customers needs andrequirements.

Itis a bulk material made of fused magnesia as raw material, with varioussuperfine powder additives and fused cement or composite resin as binder. Theproperties of it are good erosion resistance, good chemical stability, goodshock resistance, good abrasion resistance and good anti stripping property.Basic ramming mass offered by CMS INDUSTRIES is known for its chemical andphysical properties in the foreign markets.

Exceptional Thermal Performance

Our Basic Ramming Mass demonstrates a refractoriness under load (RUL) exceeding 1500C while featuring a melting point of 1700-1800C. This ensures your furnace lining holds structural integrity, reduces maintenance intervals, and supports optimal energy efficiency in high-temperature steel and iron applications.

Superior Purity and Strength

Composed mainly of CaO, MgO, SiO2, and Fe2O3, this mass offers 9598% purity and a high cold crushing strength. The low porosity and water absorption rates deliver enhanced longevity and robust performance, even under aggressive operating conditions commonly encountered in the steel industry.

Flexible Sizing and Application

Available in both granular and powdered finishes, and packaged to suit varied industrial needs, our ramming mass is adaptable for specific furnace configurations. Its customizable grain size and dependable shelf life ensure versatility and ease in handling for exporters, manufacturers, and end-users alike.

FAQs of Basic Ramming Mass:

Q: How should Basic Ramming Mass be stored to maximize its shelf life?

A: Basic Ramming Mass should be stored in a cool, dry place, away from moisture, to maintain its quality and effectiveness. When kept under these recommended conditions, it can retain its properties for up to 12 months.Q: What benefits does high alkalinity provide in Basic Ramming Mass for furnace applications?

A: High alkalinity improves resistance to slag corrosion and chemical attacks from metal oxides, making the mass especially effective in the iron and steel melting processes. This extends the service life of the furnace lining and enhances operational reliability.Q: Where is Basic Ramming Mass typically used?

A: This product is predominantly used in the steel industry, specifically for lining of induction furnaces and in foundries for iron and steel melting. Its high-temperature stability makes it suitable for demanding furnace environments.Q: When should I consider customizing the grain size of the ramming mass?

A: Customization of grain size is advisable when specific furnace design parameters or metallurgical requirements dictate unique compaction, sintering, or thermal expansion profiles. Consulting with our technical experts helps tailor the mass to your operational needs.Q: What is the process for applying Basic Ramming Mass in furnace linings?

A: The material is installed by ramming or tamping into the furnace walls or bottom in a layered manner. Proper compaction and moisture control are essential to achieve optimal density and performance during subsequent heating cycles.Q: How does the low LOI (<2%) of this ramming mass benefit its application?

A: A low loss on ignition ensures minimal volumetric change and superior stability during the initial heating of the furnace, reducing the risk of lining failure or structural compromise.Q: What distinguishes your Basic Ramming Mass as a reliable solution for furnace operations?

A: Our product delivers consistent chemical composition, high purity (95-98%), excellent dimensional stability, and robust mechanical strength. Its low porosity and adaptive packaging further ensure trouble-free storage, transportation, and handling for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Minerals Category

Mica Flakes

Product Type : Mica Flakes, Other

Application : Used in plastic rubber paints cosmetics and insulation materials

Calcite Powder

Minimum Order Quantity : 25 Metric Tons

Product Type : Minerals

Application : paint , poultry , cattle feed, white wash

Raw Kaolin Clay

Minimum Order Quantity : 25 Metric Tons

Product Type : Minerals

Application : "Ceramic body, Vitrified Tiles, Glaze Tile, Sanitary ware, Refractory, White Cement, Gray Cement "

Mica Chips

Minimum Order Quantity : 27 Metric Tons

Product Type : Minerals

Application : Paints ,Ceramics ,Rubber , Linoleum Flooring

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry