High Alumina Cement

High Alumina Cement Specification

- Chemical Composition

- High Al2O3 content, typically 50%-60% alumina

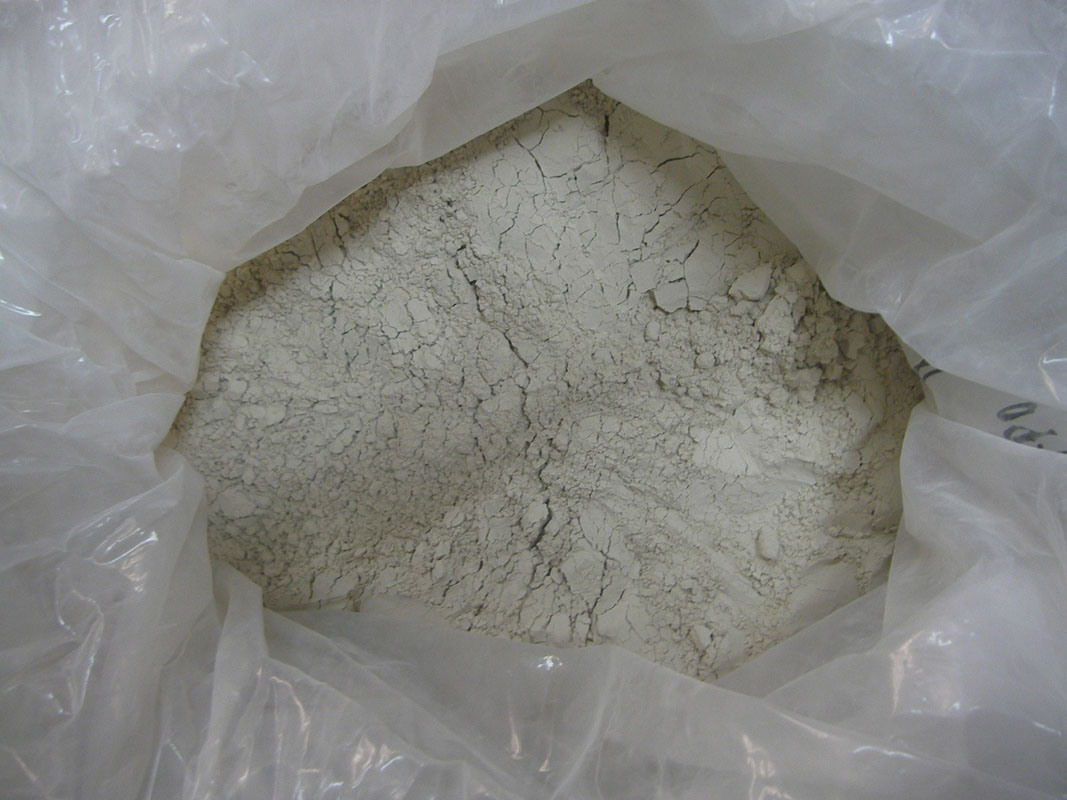

- Form

- Powder

- Hardness (%)

- High

- Usage & Applications

- Used in refractory lining, kiln furniture, and heat resistant mortars

- Surface Finish

- Fine

- Purity(%)

- 50%-60% Al2O3

- Water Absorption

- Low

- Application

- Used for refractory constructions, furnaces, and high temperature installations.

- Melting Point

- Approx. 1600C - 1700C

- Density

- 3.1 Gram per cubic centimeter(g/cm3)

- Product Type

- Refractories

- Types of Refractories

- High Alumina Refractories

- Shape

- Powder

- Porosity

- Medium

- Dimensional Stability

- Excellent at elevated temperatures

- Strength

- High initial strength, approx. 30-40 MPa after 24 hours

- Specific Gravity

- 2.9 - 3.1

- Thermal Conductivity

- Low

- Color

- Dark Gray / Black

High Alumina Cement Trade Information

- Minimum Order Quantity

- 100 Metric Tons

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Delivery Point (DP), Days after Acceptance (DA)

- Supply Ability

- 1000 Metric Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

About High Alumina Cement

High Alumina Cement (HAC) is also known as Calcium Aluminate Cement (CAC). It is widely used in production of monolithic refractories. It is also used for special construction applications, steel plants, etc. It is composed of calcium aluminates, unlike Portland cement which is composed of calcium silicates. Itis manufactured from limestone or chalk and bauxite. We are a leading Manufacture, Supplier and Exporter of Best Quality High Alumina Cement or Calcium Aluminate Cement as per the customer requirements.

Superior High Alumina Formulation

Manufactured with high purity alumina (50%-60%), this cement delivers outstanding mechanical and thermal properties. Its high initial strength, low thermal conductivity, and minimal expansion on heating make it suitable for demanding refractory applications in furnaces and kilns.

Engineered for Extreme Conditions

High Alumina Cement is designed to perform under severe environments, with a maximum service temperature up to 1600C. It provides excellent resistance against alkali attack, corrosion, and fire, ensuring long-term durability and safety for industrial installations.

Convenient Packaging and Shelf Life

Packed in 25 kg and 50 kg bags, this cement maintains a shelf life of 6-12 months if stored in dry, sealed conditions. Its fine powder consistency allows for easy mixing and application, supporting efficient construction and repair processes.

FAQ's of High Alumina Cement:

Q: How should High Alumina Cement be stored to maintain its shelf life?

A: To ensure a shelf life of 6-12 months, High Alumina Cement should be kept in a dry place and tightly sealed to prevent moisture ingress and degradation.Q: What is the recommended curing process for optimum strength development?

A: For best results and maximum strength, the cement should be cured under moist conditions after application to allow proper hydration and minimize premature drying.Q: When can high compressive strength be expected after application?

A: High Alumina Cement achieves a compressive strength of 30-50 MPa within 24 hours of application, making it suitable for rapid construction schedules.Q: Where is High Alumina Cement commonly used?

A: High Alumina Cement is primarily used in refractory constructions, such as furnace linings, kiln furniture, and other high-temperature installations due to its superior thermal and chemical stability.Q: What are the benefits of using High Alumina Cement in high-temperature applications?

A: This cement offers excellent fire resistance, negligible expansion on heating, superior corrosion and alkali resistance, and maintains dimensional stability, making it ideal for demanding heat-intensive environments.Q: How is High Alumina Cement supplied for industrial use?

A: It is available in powder form packaged in 25 kg and 50 kg bags, facilitating easy transport and handling for both large and small-scale projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Alumina Products Category

High Alumina Fire Bricks

Price 0.50 USD ($) / Piece

Price Range 0.50 - 3.00 USD ($) / Piece

Minimum Order Quantity : 2000 Pieces

Chemical Composition : Alumina content: 4090%

Form : Solid Brick

Hardness (%) : > 90%

High Alumina Hanger And Shoulder Bricks

Price 6.00 USD ($) / Piece

Price Range 0.50 - 6.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Chemical Composition : Al2O3 content > 60%, SiO2, Fe2O3

Form : Solid brick

Hardness (%) : >8 Mohs

High Alumina Bricks

Price 0.12 USD ($) / Piece

Minimum Order Quantity : 2000 Pieces

Chemical Composition : Al2O3, SiO2, small amounts of Fe2O3, TiO2

Form : Solid Brick

Hardness (%) : Mohs Hardness: 7 8

Refractory Mortar Powder

Price Range 100.00 - 700.00 USD ($) / Metric Ton

Minimum Order Quantity : 20 MT Metric Tons

Chemical Composition : Alumina, Silica, Calcium Oxide (CaO), Minor Oxides

Form : Powder

Hardness (%) : 6070%

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry