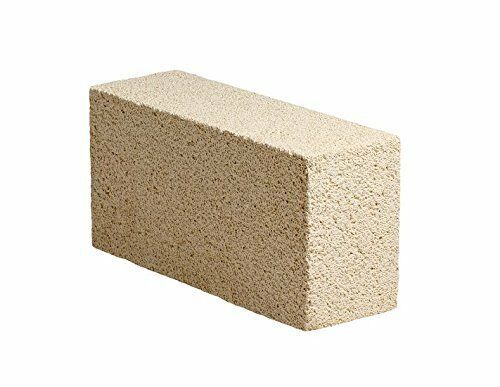

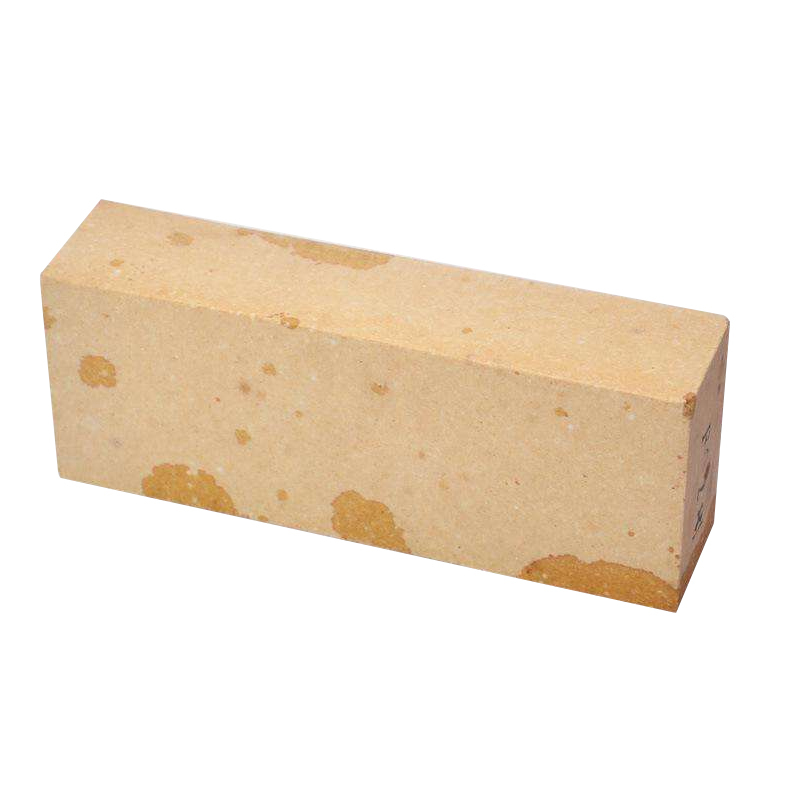

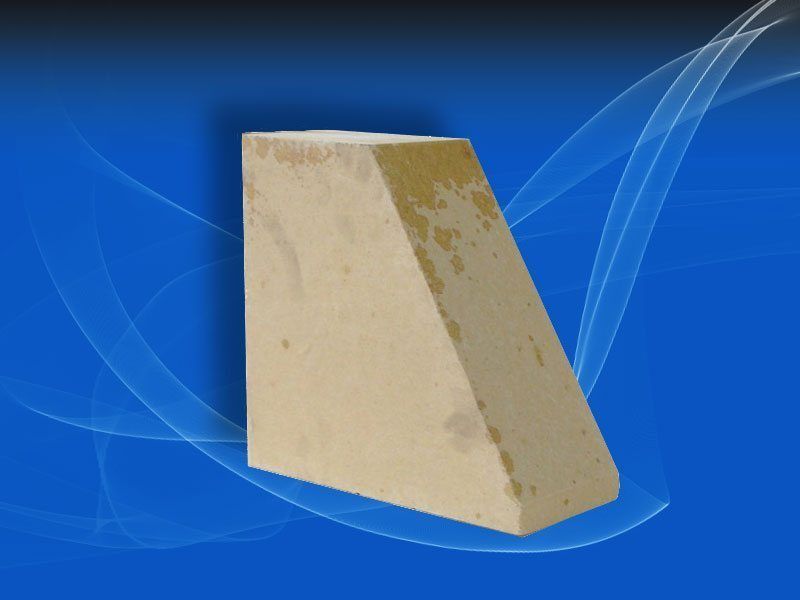

Silica Bricks

Silica Bricks Specification

- Application

- Furnace Lining, Coke Oven, Glass Furnace, Hot Blast Stoves, Electric Arc Furnace

- Purity(%)

- SiO2 > 95%

- Density

- 1.95 Gram per cubic centimeter(g/cm3)

- Water Absorption

- < 5%

- Form

- Solid Brick

- Surface Finish

- Smooth

- Hardness (%)

- 6575

- Melting Point

- 1710C

- Chemical Composition

- SiO2, Fe2O3, Al2O3, CaO

- Usage & Applications

- Used in thermal processing industries, glass manufacturing, steel plants, coke ovens, and other high-temperature furnaces

- Product Type

- Refractories

- Types of Refractories

- Acid Refractory

- Shape

- Rectangular, Arch, Customized

- Porosity

- 1622%

- Dimensional Stability

- Excellent at High Temperature

- Strength

- Cold Crushing Strength > 35 MPa

- Specific Gravity

- 1.81.95

- Thermal Conductivity

- 1.01.2 W/mK

- Color

- Light Yellow to White

- Packing Type

- Wooden Pallet/Standard Export Packaging

- Resistance to Acid Slag

- High

- Permanent Linear Change (PLC)

- <0.2% at 1450C

- Apparent Porosity

- 2022%

- Thermal Expansion

- Significant at temperatures above 1390C

- Refractoriness Under Load (RUL)

- 1400C minimum

- Size

- 230mm x 114mm x 65mm (standard), custom sizes available

- Manufacturing Process

- Pressed and fired at high temperature

- Bulk Density

- 1.851.95 g/cm

Silica Bricks Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Western Union, Delivery Point (DP), Telegraphic Transfer (T/T), Days after Acceptance (DA)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America

About Silica Bricks

Silica bricks are acid refractory materials with good resistant ability to acid slag.The SiO2 content of silica brick takes up 94%. The larger amount of the SiO2 content of silica raw materials, the higher the refractoriness. We are a leading Manufacture, Supplier and Exporter of Best Quality of Silica brick as per the customer's needs and requirements.

Superior Thermal Stability for Industrial Furnaces

Silica Bricks exhibit significant thermal expansion above 1390C, but maintain excellent dimensional stability even in demanding environments. Their acid refractory nature and resistance to chemical attack ensure reliable performance in furnaces, glass manufacturing, steel plants, and coke ovens. With a refractoriness under load of at least 1400C, these bricks provide durable protection for your heat-intensive operations.

High Purity SiO2 Content Guarantees Longevity

Containing more than 95% SiO2, Silica Bricks are engineered for outstanding refractoriness and low permanent linear change, even at temperatures reaching 1450C. The superior chemical composition supports extended service life and optimal performance under aggressive conditions encountered in thermal processing industries, ensuring value for your investment.

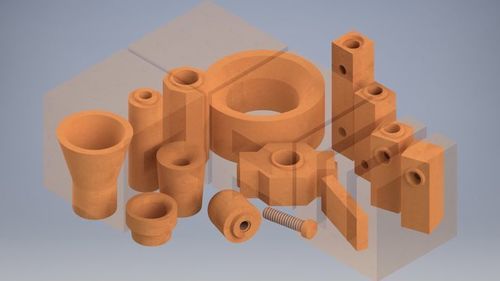

Customizable Sizes and Shapes for Diverse Applications

Whether your project demands the standard 230mm x 114mm x 65mm size or tailored dimensions, Silica Bricks can be manufactured to fit specific design requirements, including rectangular and arch forms. This flexibility enables seamless integration into various furnace designs. Transportation is streamlined with wooden pallet and export packaging, minimizing breakage during shipping.

FAQ's of Silica Bricks:

Q: How are Silica Bricks manufactured for high-temperature applications?

A: Silica Bricks are produced by pressing raw materials containing high-purity SiO2, followed by firing them at elevated temperatures. This process imparts unique properties such as excellent dimensional stability and resistance to acid slag in thermal environments.Q: What is the main benefit of using Silica Bricks in thermal processing industries?

A: The main benefit is their high refractoriness under load (minimum 1400C), which ensures the bricks retain strength, resist chemical attack, and provide long-lasting insulation in high-temperature furnaces like glass plants, coke ovens, and steel manufacturing units.Q: Where can Silica Bricks be effectively used?

A: They are widely used as lining materials in furnaces, glass manufacturing units, steel plants, coke ovens, hot blast stoves, and electric arc furnaces, thanks to their durability and acid refractory nature.Q: What sizes and shapes of Silica Bricks are available?

A: The standard size offered is 230mm x 114mm x 65mm, but custom sizes and shapes-including rectangular, arch, and other configurations-can be manufactured to cater to specific requirements.Q: What chemical composition ensures the durability of Silica Bricks?

A: Silica Bricks comprise over 95% SiO2 along with minor components like Fe2O3, Al2O3, and CaO. This composition contributes to their exceptional acid resistance and mechanical strength at high temperatures.Q: How does significant thermal expansion affect the usage of Silica Bricks?

A: Although Silica Bricks exhibit significant thermal expansion above 1390C, their excellent dimensional stability at high temperature ensures consistent and safe performance as refractory linings within industrial settings.Q: What packaging is used for exporting Silica Bricks internationally?

A: For safe transport, Silica Bricks are packed on wooden pallets or in standard export packaging, which provides enhanced protection against breakage during shipping and delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bricks Category

Insulating Fire Bricks

Minimum Order Quantity : 500 Pieces

Melting Point : 1780C

Chemical Composition : AluminaSilicate

Usage & Applications : Ideal for thermal insulation in industrial furnaces and kilns

Product Type : Refractories

Alumina Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Melting Point : 18001900C approx.

Chemical Composition : Alumina (65%), Magnesia (1525%), Carbon (815%)

Usage & Applications : Ladle Lining, EAF, Steel Making Furnaces

Product Type : Refractories

Bottom Pouring Sets

Price Range 40.00 - 160.00 USD ($) / Metric Ton

Minimum Order Quantity : 400 Metric Tons

Melting Point : Up to 1700C

Chemical Composition : Al2O3, SiO2, CaO, Fe2O3; AluminoSilicates

Usage & Applications : Bottom Pouring of Ingots, Steel Casting

Product Type : Refractories

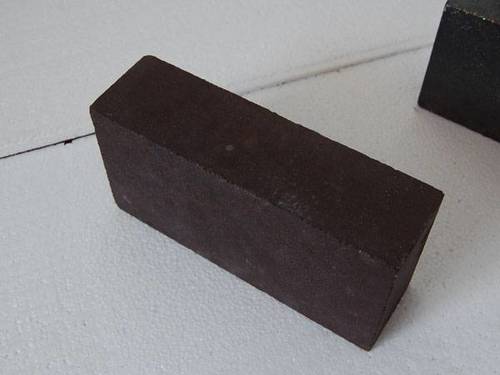

Magnesia Carbon Bricks

Price Range 2.50 - 5.00 USD ($) / Piece

Minimum Order Quantity : 500 Pieces

Melting Point : 2800C (approx.)

Chemical Composition : MgO > 70%, C = 1020%

Usage & Applications : Steel Industry, ladle lining, converters, electric arc furnace walls and roofs

Product Type : Refractories

|

CMS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry